Cooling water circulation system applicable to high-flow test platform

A technology of cooling water system and test bench, which is applied in the direction of measuring device, engine test, machine/structural component test, etc. It can solve the problem that water cannot be replenished in time, and achieve the effect of reducing workload, simplifying the system and reducing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described in detail with reference to the accompanying drawings and embodiments.

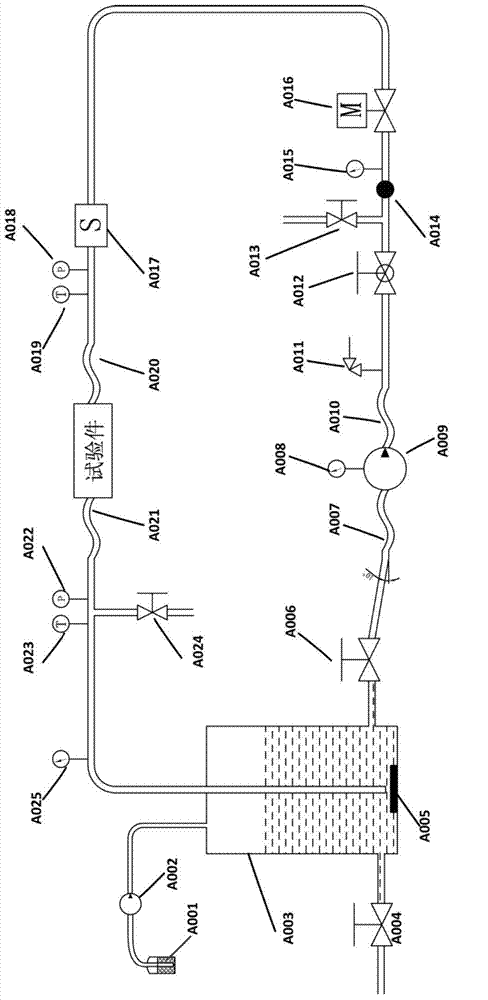

[0024] The present invention is a cooling water system suitable for large flow test benches, such as figure 1 As shown, specifically:

[0025] The barreled distilled water A001 is connected to the small water pump A002, and the water tank A003 is connected with the small water pump A002, the manual stop valve A004, and the manual stop valve A006. The damping block A005 is placed at the bottom of the water tank A003. Block A005 is located directly below the water pipe, and maintains a certain space distance to release the pressure of the distilled water coming out of the return pipe to prevent it from impacting the water tank A003. The water pipe is equipped with a pressure sensor A022, a temperature sensor A023 and a pressure gauge A025 to detect Distilled water state parameters, and also set a three-way connection manual shut-off valve A024, manual ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com