Extractive rectification process control method based on effective relative gain matrix method

A relative gain matrix and extractive distillation technology, applied in the field of extractive distillation process control based on the effective relative gain matrix method, can solve the problem that the small changes of input and output cannot be eliminated, the controlled variable fluctuates greatly, and deviates from the initial setting state. and other problems to achieve the effect of maintaining product qualification, maintaining stability, and maintaining process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, but not to limit the present invention. In addition, it should be noted that, for the convenience of description, only parts related to the present invention are shown in the drawings but not all content.

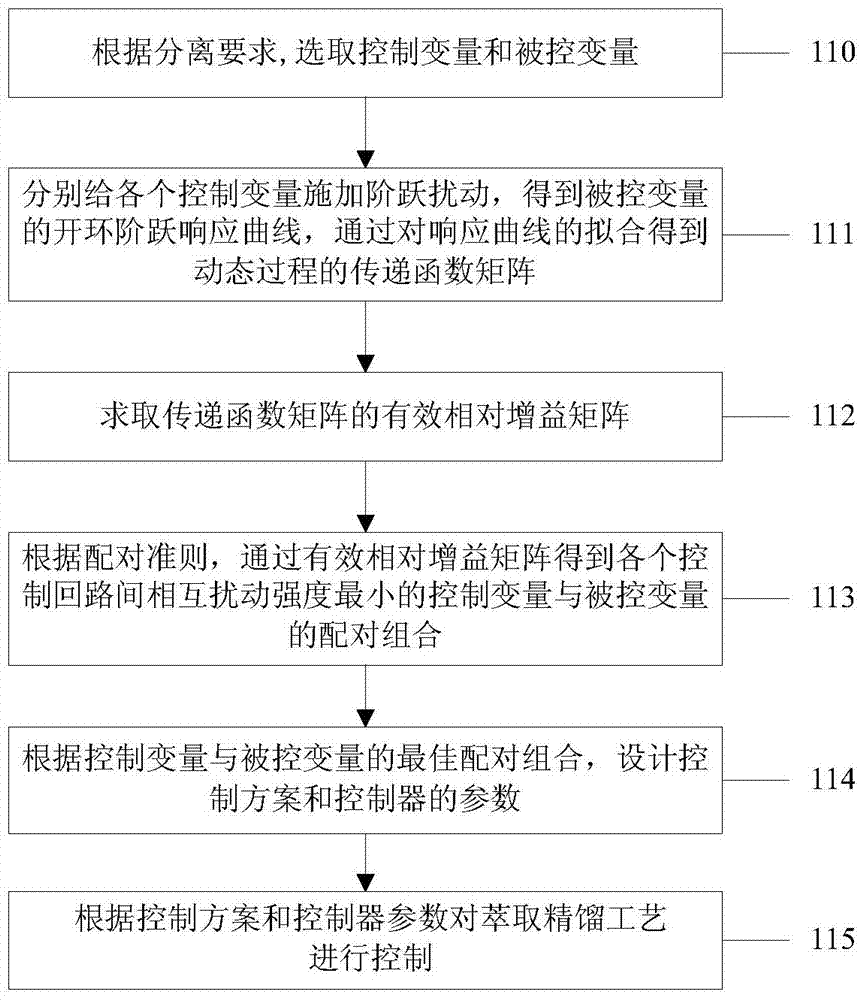

[0045] Such as figure 1 As shown, the present invention provides a kind of extractive distillation process control method based on effective relative gain matrix method, and the method comprises the following steps:

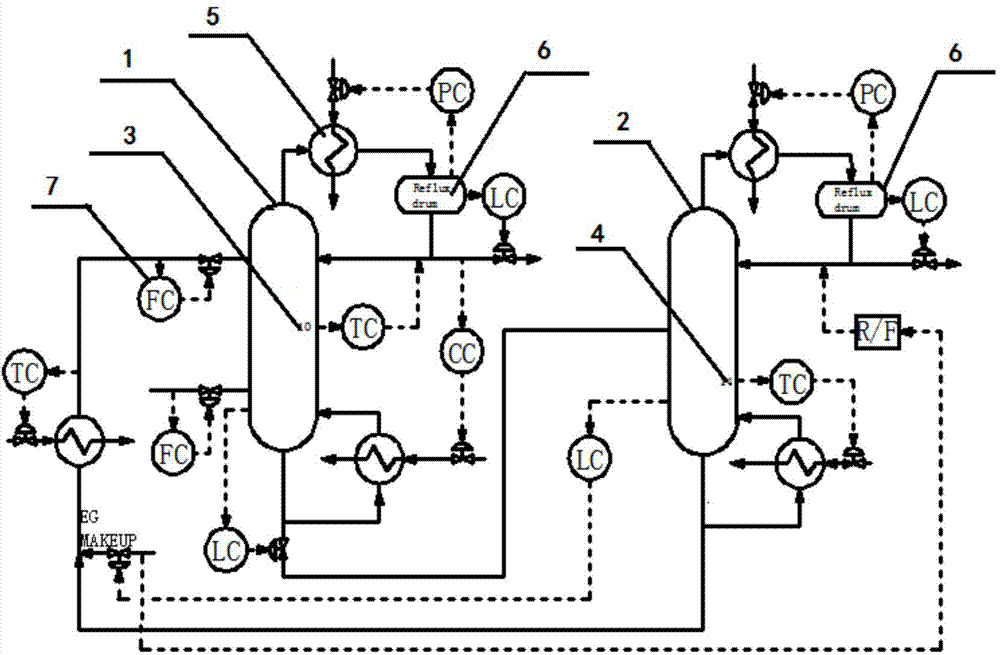

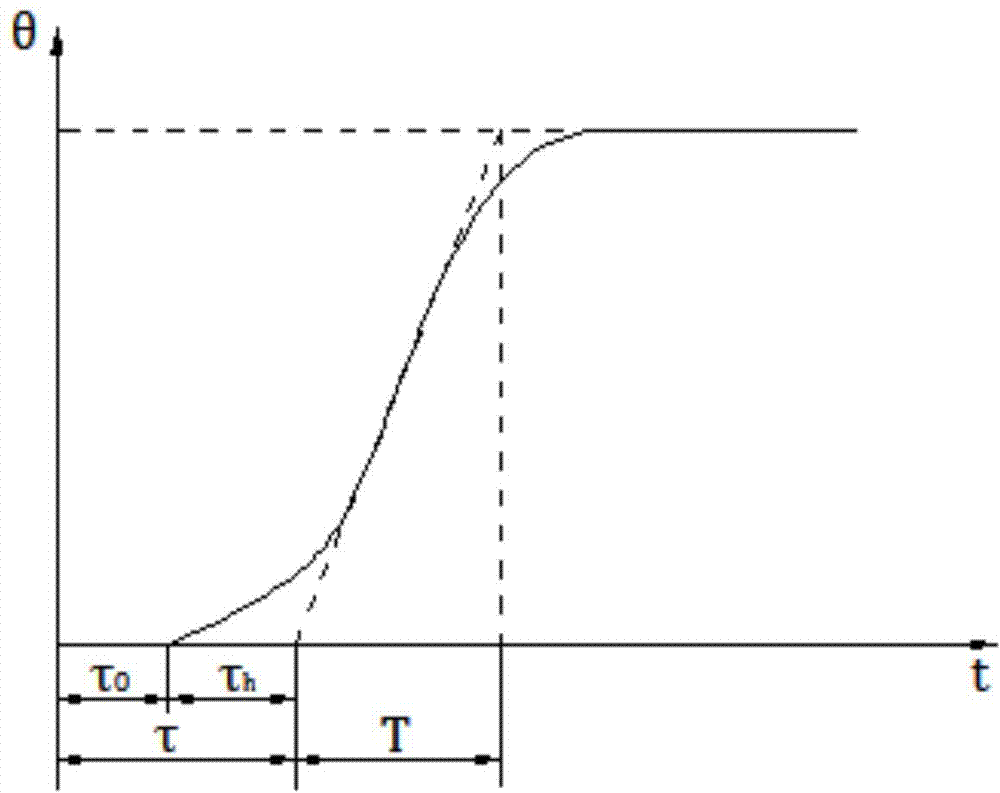

[0046] Step 110: according to separation requirements, select the reflux ratio of the extractive distillation tower, the reflux ratio of the extractant recovery tower, the heat load of the reboiler of the extractive distillation tower and the heat load of the reboiler of the extractant recovery tower as control v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com