Passive light-splitting RS-485 optical fiber bus local side system

A RS-485, bus station technology, applied in the field of industrial manufacturing, can solve the problem of not guaranteeing high-speed long-distance communication requirements, communication rate decline, etc., to achieve the effect of improving anti-lightning protection ability, cost saving, and system simplicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

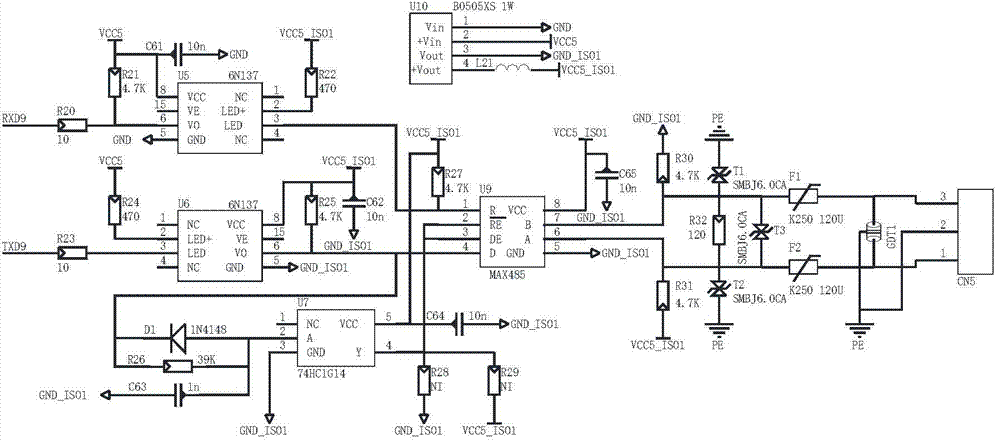

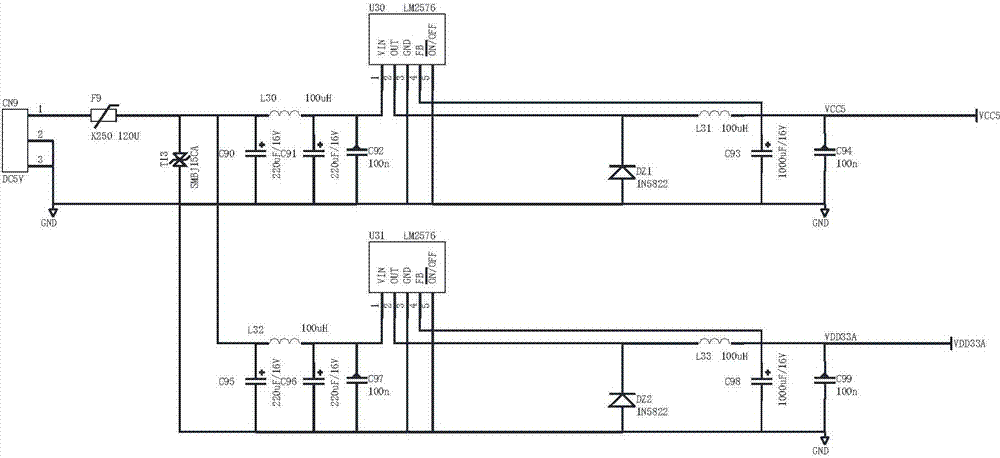

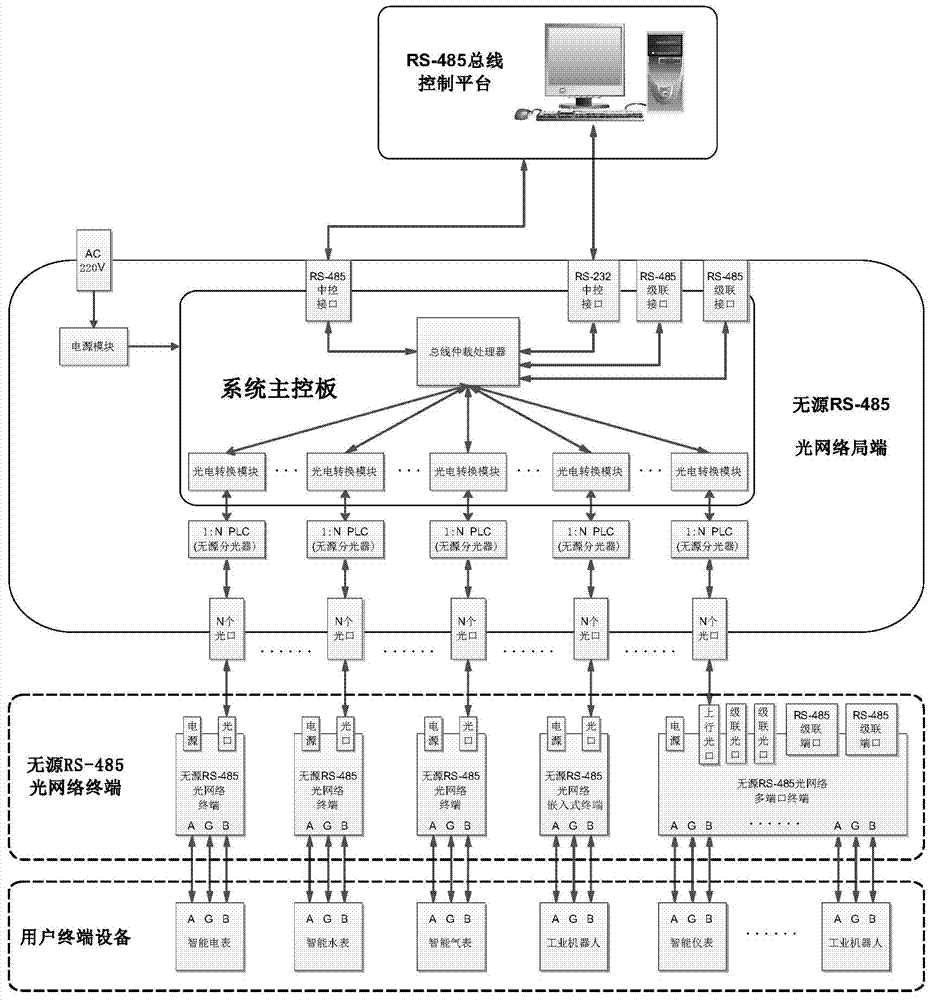

[0048] Example: see Figure 1 to Figure 21 , the present embodiment provides a passive optical splitting RS-485 optical fiber bus local end system, its two ends are respectively connected to the RS-485 bus control end of the passive optical splitting industrial optical fiber bus and the passive RS-485 optical network terminal; it includes Interconnected power supply module, main control board, multiple planar waveguide optical splitters and multiple optical ports, wherein the main control board includes RS-232 central control interface, RS-485 central control interface, two RS -485 cascading interface, a plurality of photoelectric conversion modules and bus arbitration processors, the RS-232 central control interface and two RS-485 cascading interfaces are connected to the bus arbitration processor and the RS-485 bus control end, the multiple One end of each photoelectric conversion module is connected to the bus arbitration processor, the other end is connected to one end of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com