Tobacco leaf harvesting method and cigarette manufacturing method

A harvesting method and technology of tobacco leaves, applied in the field of tobacco, can solve the problems of ignorance of the physiological and biochemical changes in the mature tobacco leaves of tobacco leaves, etc., and achieve the effects of improving operability, pure and comfortable aftertaste, and strong comprehensiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0064] Embodiment 1: according to the tobacco leaf that the method for the present invention gathers

[0065] 1. Harvesting of tobacco leaves

[0066] Harvest as follows:

[0067] (1) Lower leaves

[0068] Leaf veins, 2 / 3 of the main veins turn white, from the base of the leaf to more than the tenth branch or more than 65% of the leaf area turns yellow or basically turns yellow, both sides of the branch are slightly green; the hair on the tip of the leaf is slightly receded, and the angle between the stem and the leaf is close to 90° °.

[0069] (2) Middle leaves

[0070] The greenness of the leaves is reduced, the surface of the leaves is light yellow, the tips and margins of the leaves turn yellow and white, the main veins are completely white, 1 / 3 to 2 / 3 of the branch veins turn white, the base of the leaves is yellowish, and 80% of the leaves are from the base to the sixth branch The leaf area turns yellow or basically turns yellow, and the sides of the branch veins a...

Embodiment 2

[0075] Example 2: Tobacco leaves harvested according to traditional methods

[0076] 1. Harvesting of tobacco leaves

[0077] The tobacco leaves of Example 1 are collected from the same field and the same year, and the planting methods of the tobacco leaf varieties and tobacco seedlings are also the same.

[0078] Specifically, harvest according to the following methods:

[0079] Lower leaves: leaf surface yellow-green, 6-7 percent yellow, main veins whitened by more than 1 / 2;

[0080] Middle leaves: the leaf surface is light yellow, 7-8 percent yellow, and more than 2 / 3 of the main veins turn white;

[0081] Upper leaves: Leaf surfaces are light yellow, 8-9 percent yellow, and more than 3 / 4 of the main veins turn white.

[0082] 2. Baking of tobacco leaves

Embodiment 3

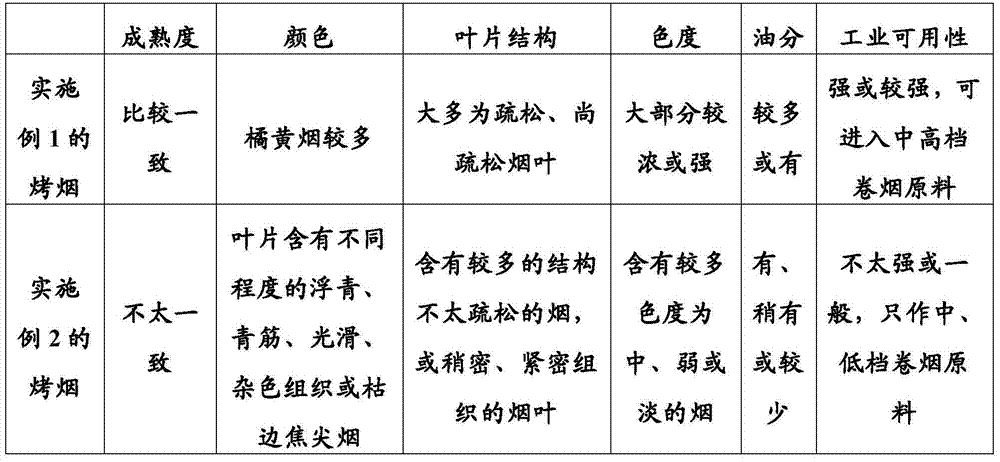

[0084] Embodiment 3: the comparison of the macro index of the tobacco leaf harvested by different methods

[0085] 1. Experimental samples

[0086] The tobacco leaves of different harvesting methods of Examples 1 and 2 were processed through the same curing process.

[0087] 2. Experimental method

[0088] The metrics for comparison are shown in Table 1 below.

[0089] Leaf structure, chroma, and oil content are judged according to the national standard of "Cured Tobacco" (GB 2635-92, Flue-cured Tobacco [S]) and physical standard samples.

[0090] 3. Experimental results

[0091] As in Table 1 below.

[0092] Table 1: Comparison of macro indicators of tobacco leaves harvested by different methods (upper leaf, middle leaf and lower leaf are compared as a whole)

[0093]

[0094] The results show that the performance of the roasted tobacco leaves harvested by the method of the present invention is relatively consistent in maturity, and the roasted leaves have no or ver...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com