A mixed-drink production line

A production line and hybrid technology, applied in food science and other directions, can solve the problems of poor taste of mixed drinks, affecting product quality, easy coking, etc., to ensure the quality of mixed drinks and avoid local coking effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

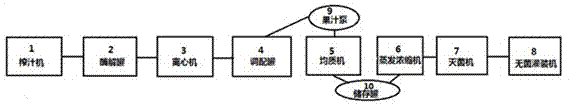

[0010] Such as figure 1 As shown, a mixed beverage production line includes juice extractors, enzymolysis tanks, centrifuges, blending tanks, homogenizers, evaporative concentrators, sealed tubular heat exchangers, and filling machines connected in sequence. Between the centrifuge and the homogenizer, a blending tank and a juice pump for delivering the juice in the blending tank to the homogenizer are arranged, and between the homogenizer and the tubular heat exchange There is a storage tank between the devices.

[0011] The above content is a further detailed description of the present invention in conjunction with specific preferred embodiments, and it cannot be assumed that the specific implementation of the present invention is limited to these descriptions. For those of ordinary skill in the technical field of the present invention, without depar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com