Mushroom drying equipment

A technology for drying equipment and shiitake mushrooms, which is applied in the fields of application, food processing, food science, etc. It can solve the problems of shiitake mushroom pollution, shiitake mushroom mildew, and moisture cannot be discharged in time, so as to achieve uniform heating and prevent mildew.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Specific embodiments of the present invention are described below in conjunction with accompanying drawing:

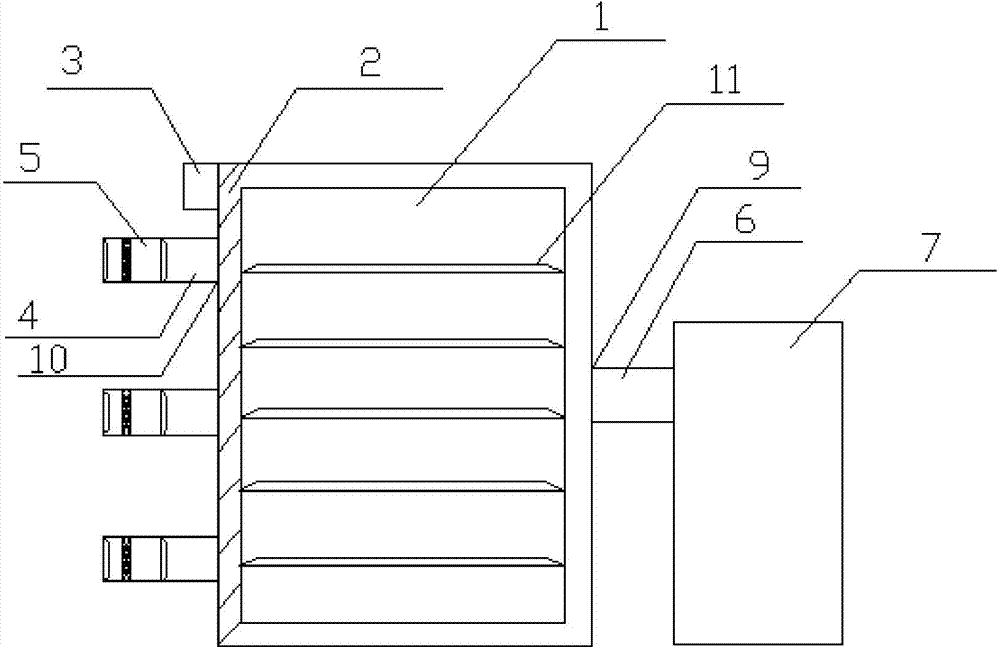

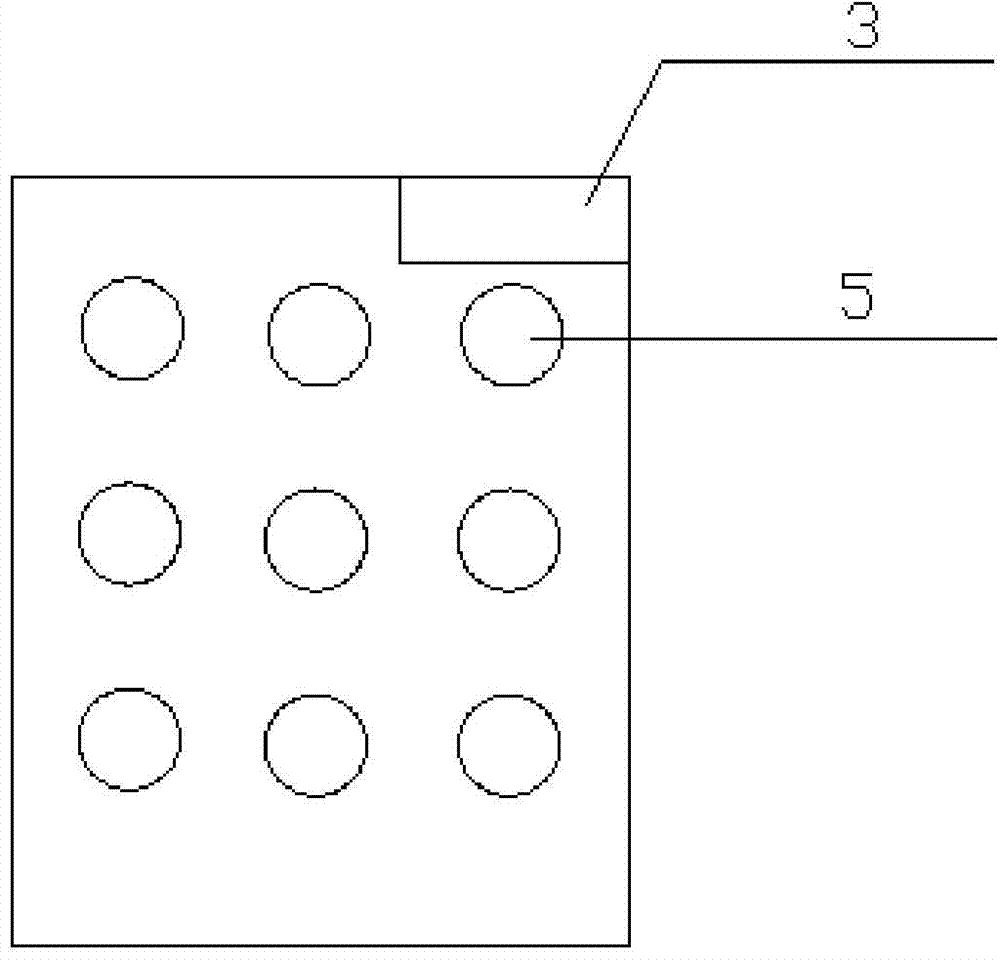

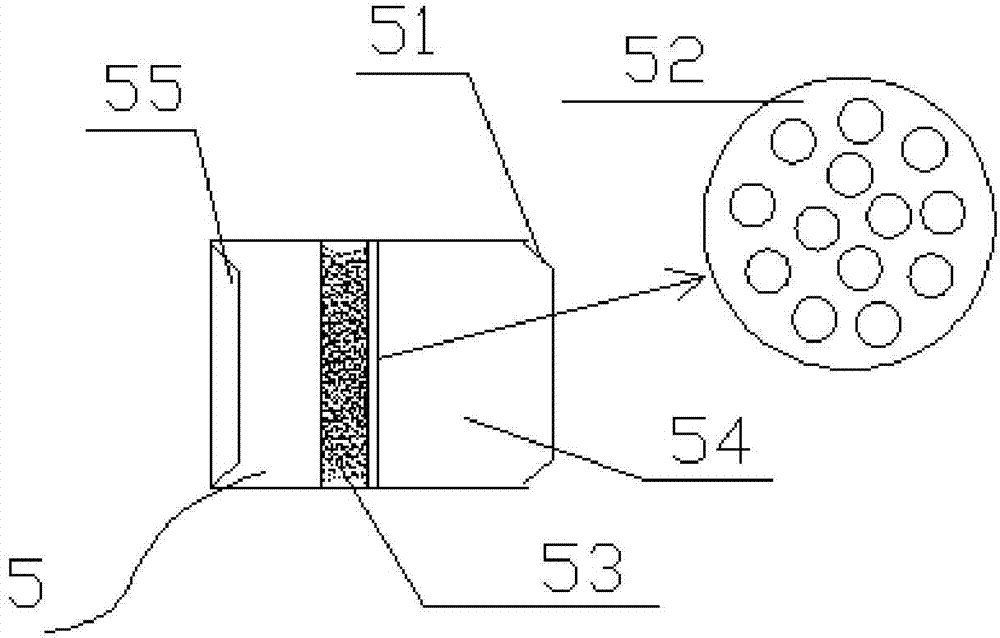

[0028] like figure 1 , 2 , 4, a mushroom drying equipment, including a drying box 1, the drying box 1 is a cabinet structure, wherein the front is an oven door 8, the upper left side of the drying box 1 is provided with a power distribution control Box 3, a temperature and humidity sensor is installed inside the drying box 1, and a temperature and humidity display device is installed on the outside of the drying box 1, which can monitor the temperature and humidity inside the drying equipment at any time. Several air inlets 10, the number is preferably 9, evenly distributed on the left side of the drying box 1, each air inlet 10 is connected to an inlet pipe 4, and the inlet pipe 4 is connected to the dustproof device 5, and the drying box 1 is provided with The side with the air inlet 10 is provided with an air outlet 9, which is located at the center, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com