Sheet metal stamping automated production device

A production device and metal sheet technology, applied in the direction of feeding device, positioning device, storage device, etc., can solve the problem of single function, etc., and achieve the effect of low environmental pollution, high precision and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

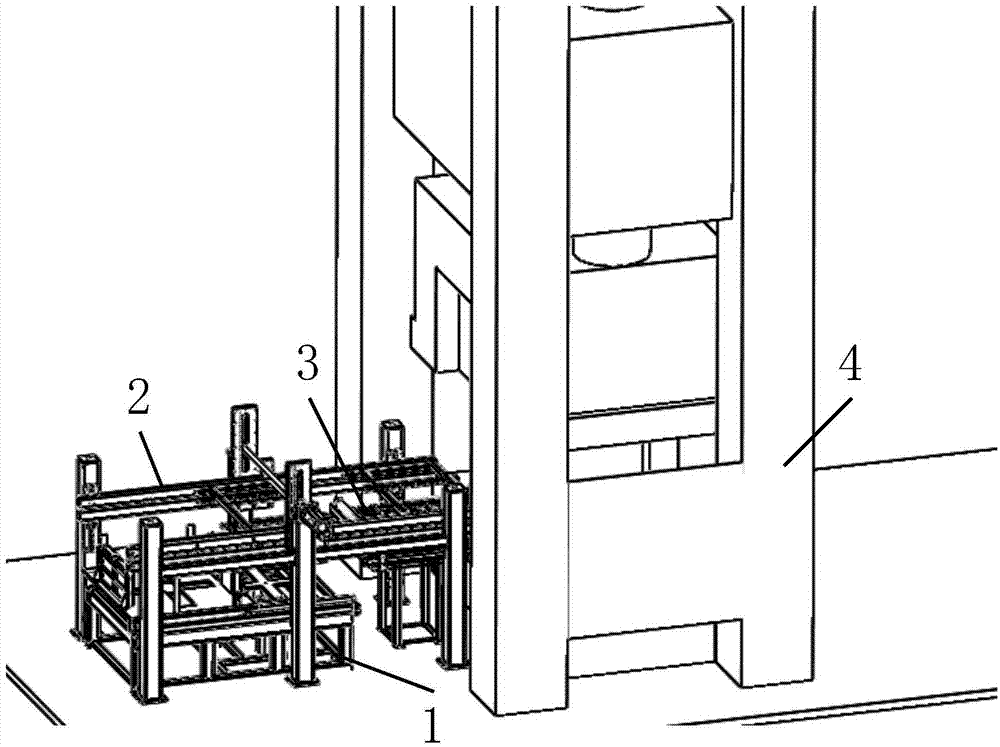

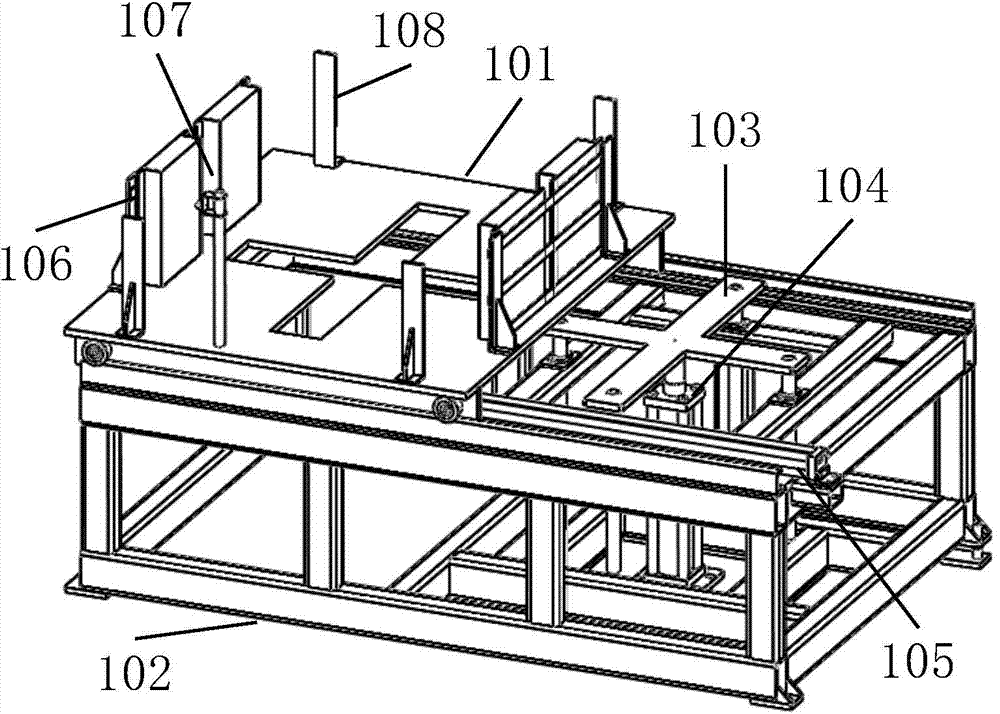

[0025] An automatic production device for sheet metal stamping, comprising a stacking mechanism 1, a feeding mechanism 2, an oiling positioning mechanism 3, and a press 4; On one side of the feed opening, the stacking mechanism 1 and the oiling positioning mechanism 3 are located below the feeding mechanism 2, and the oiling positioning mechanism 3 is located on the side close to the press 4, and the stacking mechanism 1 is located on the side away from the press 4 .

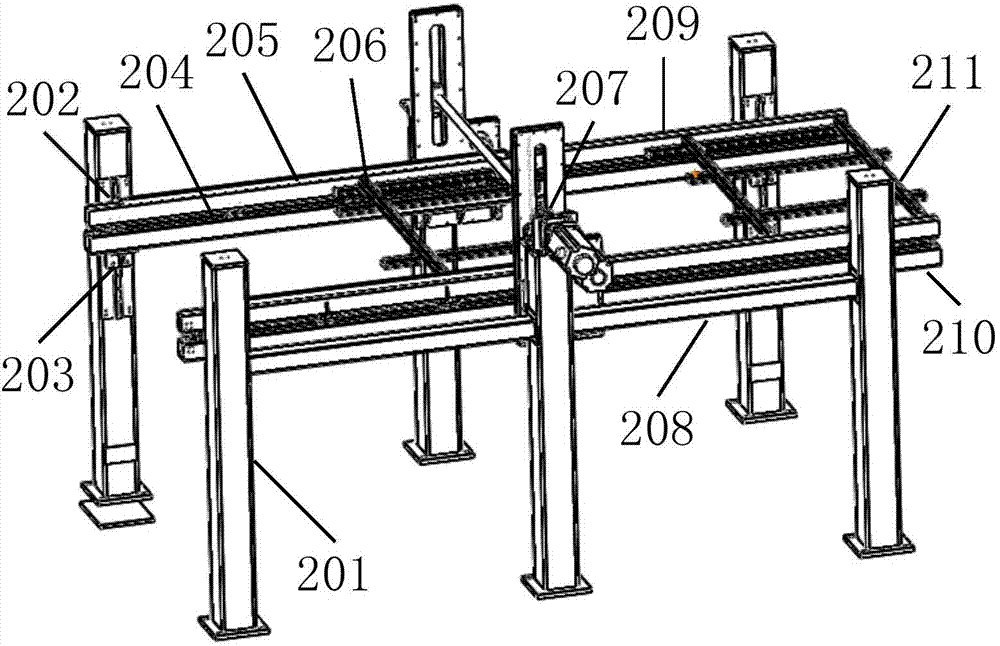

[0026]The above-mentioned feeding mechanism 2 includes a feeding column 201, a Z linear slide rail 202, a Z slide block, an X slide block, an X linear slide rail 204, a cantilever 209, a cantilever beam 210, a cantilever beam support seat 203, a power unit 207, and an X rack 205. The first end picker 206 and the second end picker 211; the six pick-up columns 201 are divided into two rows, three in each row, arranged parallel to each other, fixed on the ground, and together form two adjacent rectangular frames, Z...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com