Method for manufacturing holes in different-material laminated structures through automatic drilling and riveting system

A technology of automatic drilling and riveting, laminated structure, applied in aircraft parts, transportation and packaging, etc., can solve the problems of drilling quality degradation, vibration phenomenon, inferiority, etc., achieve high-precision processing, improve drilling quality, and improve processing efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described in detail below in conjunction with examples, but the embodiments of the present invention are not limited thereto.

[0023] A method for making holes in laminated structures of different materials by using an automatic drilling and riveting system, comprising:

[0024] Before using the automatic drilling and riveting system for test processing, first use the existing CNC processing equipment to conduct experiments, and obtain the corresponding experimental processing parameters;

[0025] Referring to the experimental processing parameters, it is applied to the automatic drilling and riveting system for hole-making tests, so as to obtain the best hole-making processing parameters of the automatic drilling and riveting system.

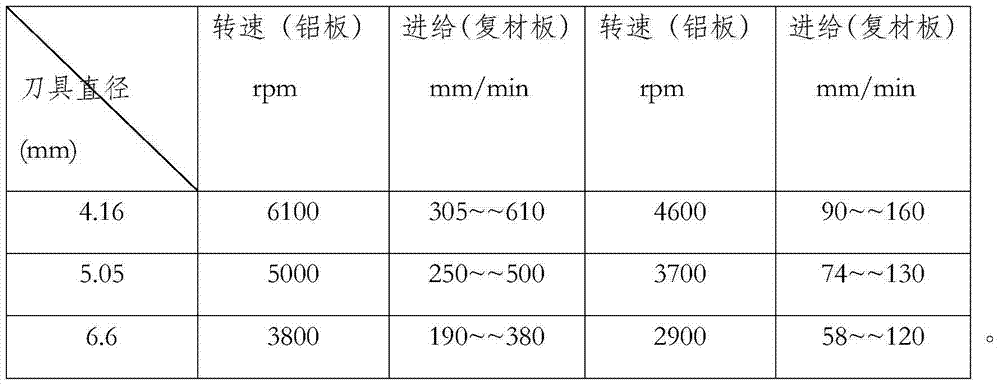

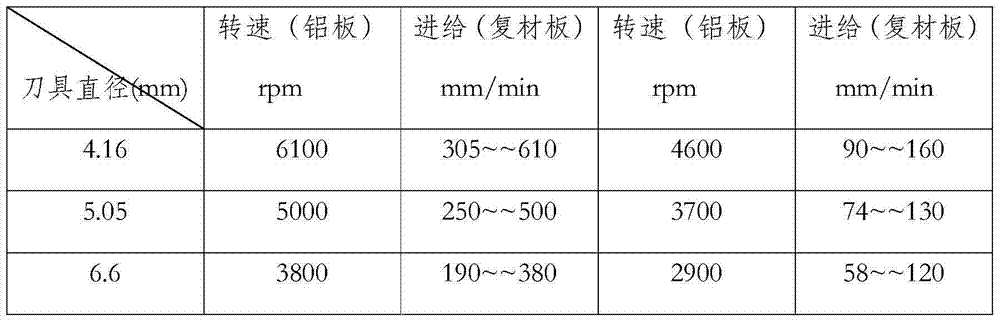

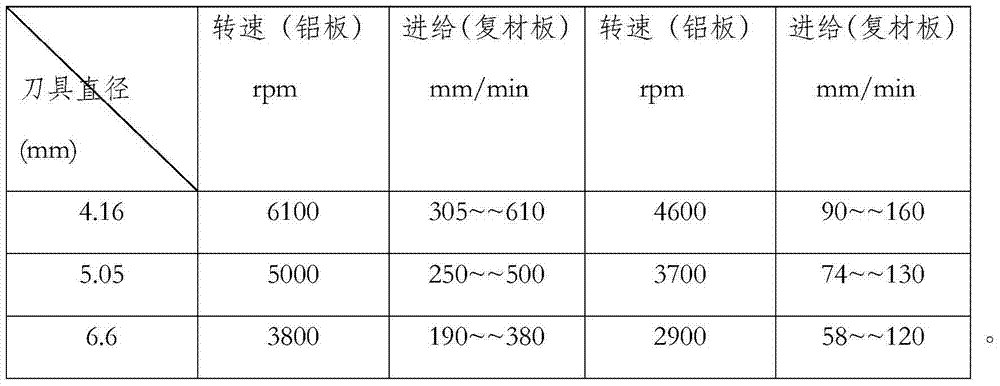

[0026] In this example, the research on the selection of automatic hole-making processing parameters for different material laminated structures is to obtain a reasonable parameter, which is applied...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com