Full-automatic power head slot milling machine tool

A power head and fully automatic technology, which is applied in milling machine equipment, automatic control devices, milling machine equipment details, etc., can solve the problems of low processing efficiency and achieve the effects of improving efficiency and quality, fast and precise positioning, and smooth adjustment actions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described in detail below in conjunction with the accompanying drawings, but does not constitute any limitation to the present invention. Similar component numbers in the accompanying drawings represent similar components. As mentioned above, the present invention provides a fully automatic power head slot milling machine tool, which realizes fully automatic machining.

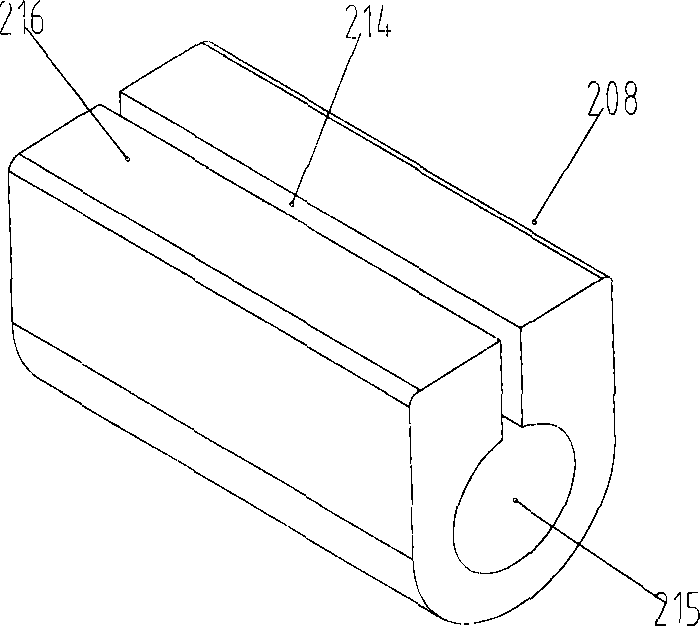

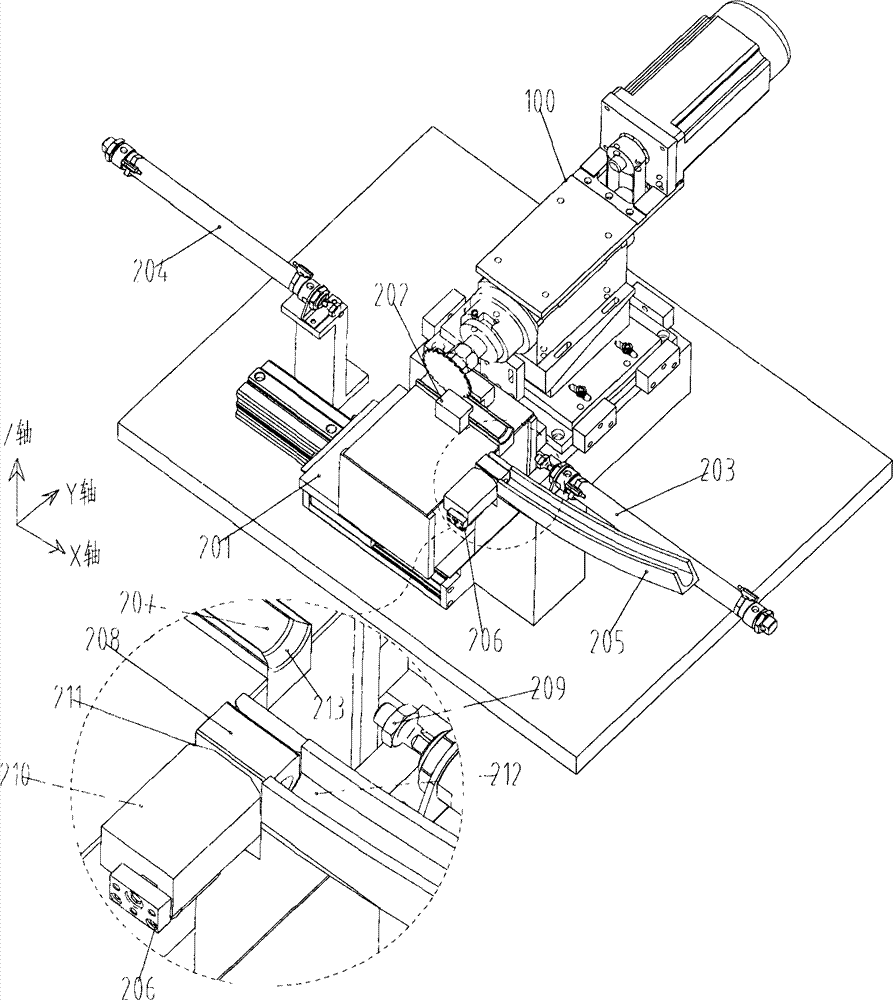

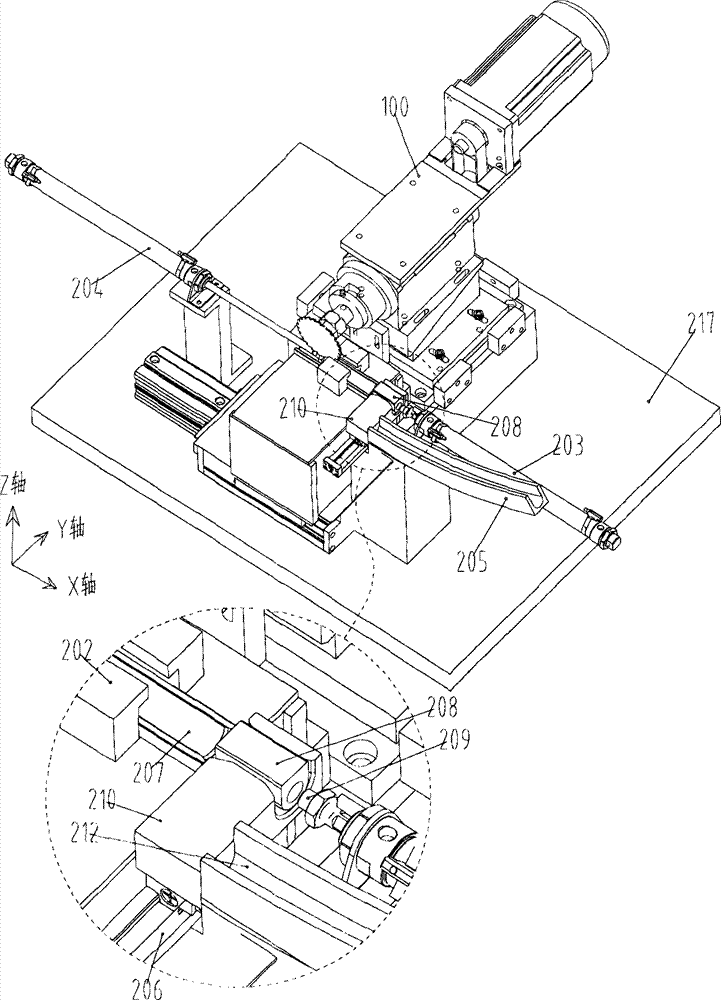

[0035] Figures 1 to 6 It is a structural schematic diagram of the automatic power head slot milling machine tool of the present invention, Figure 7 , 12 It is a structural schematic diagram of the power head assembly and the base of the automatic power head slot milling machine tool of the present invention, Figure 8 is a structural schematic diagram of the power head assembly in the present invention, Figure 9 , 10 , 11 are structural schematic diagrams of the base in the present invention.

[0036] A fully automatic power head slot milling machine tool, c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com