Device and method for achieving laser high-cavitation-strengthening efficiency

A laser and high-efficiency technology, applied in laser welding equipment, welding equipment, metal processing equipment, etc., to achieve the effect of improving efficiency, improving processing efficiency, and high utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

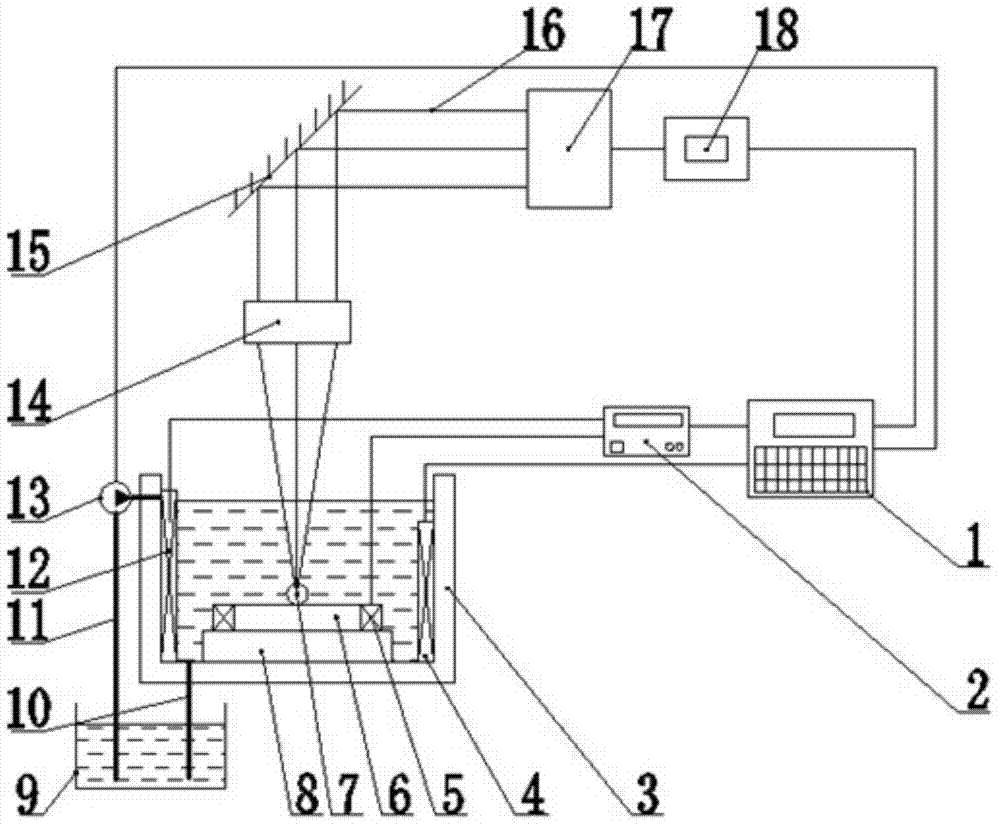

[0023] Install the workpiece Cu target on the clamping device, adjust the laser to focus on the upper side of the Cu target surface, and the process parameters of the pulsed Nd:YAG laser are: output wavelength 1.06 μm, pulse width 10 ns. Fill water into the water tank 3 through the liquid pump 13. From the time when the pure water in the water tank 3 overflows the surface of the workpiece, as the liquid height increases, the loss of water to the energy of the laser beam is also increasing. First, add the liquid height in the water tank to 200mm, and then gradually reduce the liquid height. It is found that when the liquid height reaches about 100mm, the high-efficiency strengthening effect of laser cavitation on the target is the best. Ensure that the height of the pure water in the tank remains constant, starting from room temperature, and heating the pure water to 70°C. Experiments have proved that when the temperature of the liquid is low, the strengthening effect on the ta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com