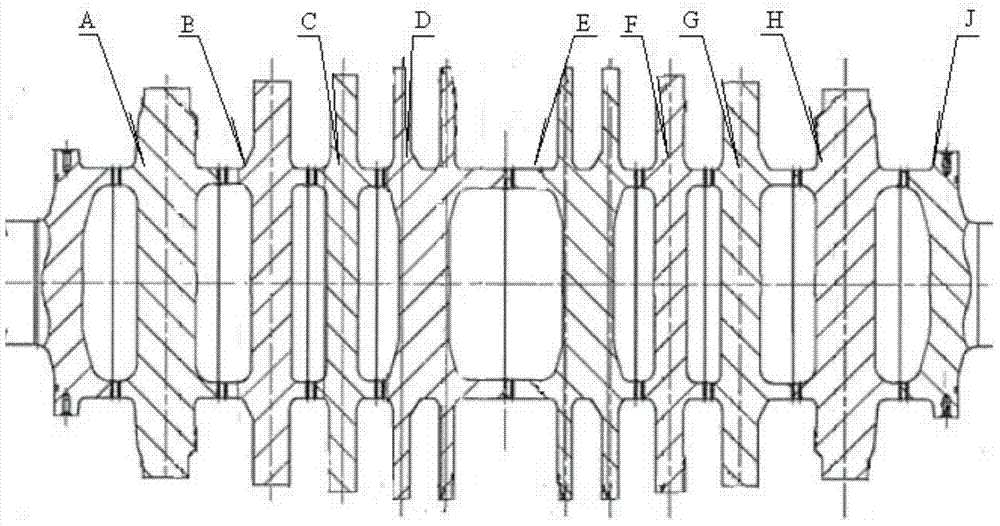

Device for automatically detecting weld joint of low-pressure welding rotor of steam turbine for nuclear power station

An automatic detection device and welding rotor technology, which is applied in the direction of measuring devices, auxiliary devices, welding equipment, etc., can solve the problems of automatic inspection of weld seams of low-pressure welding rotors of steam turbines in nuclear power plants, etc., and achieve rapid installation and positioning, fast and convenient installation, To achieve the effect of concentricity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

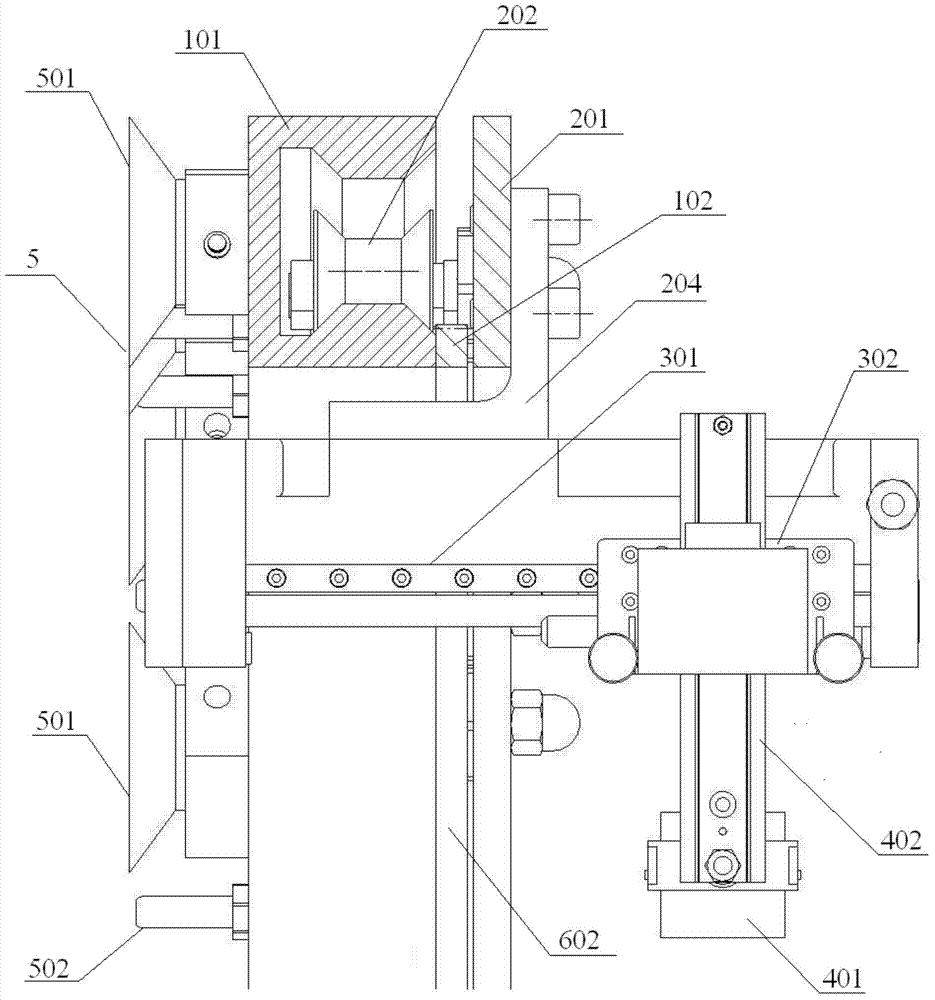

[0031] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

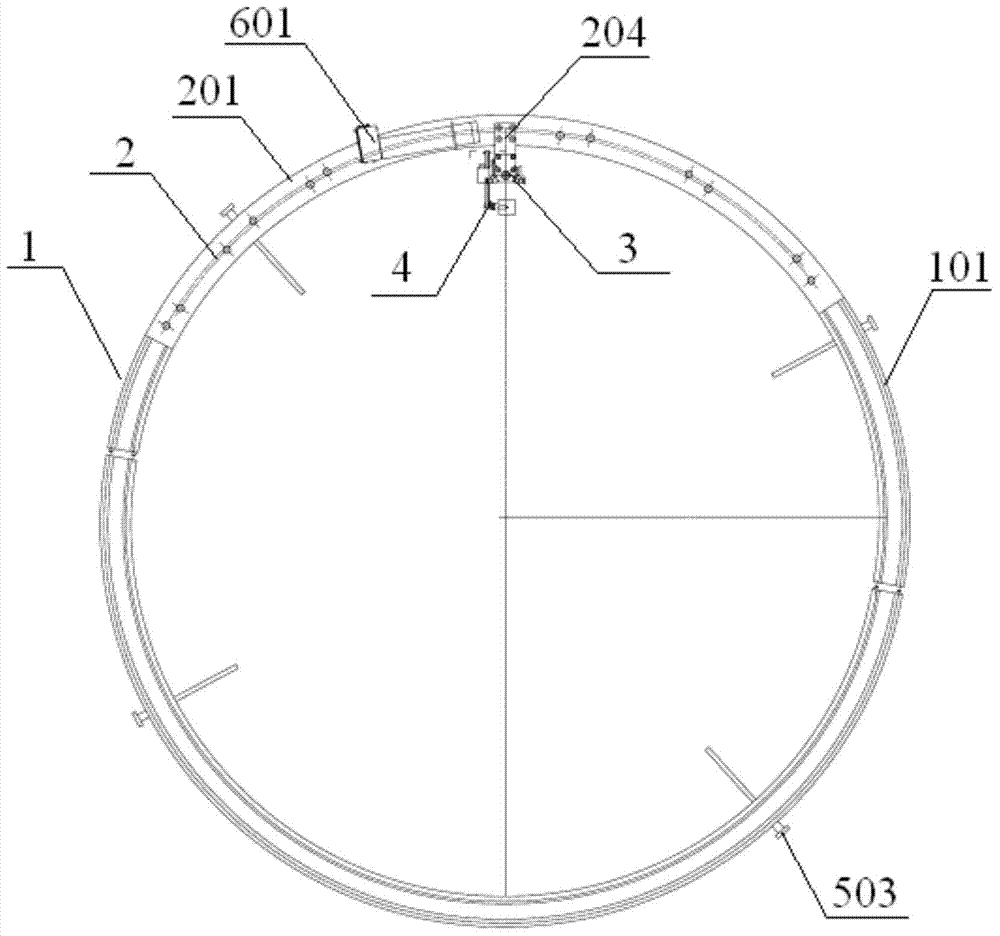

[0032] The present invention is an automatic detection device for low-pressure welded rotor welds of a steam turbine in a nuclear power plant, comprising a guide rail assembly 1, a circumferential movement assembly 2, an axial drive assembly 3, a probe assembly 4, a positioning assembly 5, and a circumferential drive assembly 6;

[0033] The guide rail assembly 1 includes a quick clamp assembly, a semi-circular guide rail 101, and a half ring gear 102;

[0034] The semi-circular guide rail 101 is a semi-circular track structure, and its guide rail groove profile is "H" shape, and the opening direction of the guide rail groove is consistent with the axis direction of the semi-circular track structure; the half ring gear 102 is connected to the Said semicircular guide rail 101 is close to the end face of said guide rail slot opening side of its inner circ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com