Automatic assembly machine for guide rod rubber bushings

A rubber bushing and assembly machine technology, applied in metal processing, metal processing equipment, hand-held tools, etc., can solve problems such as customer complaints, insufficient detection, and discoloration of guide rods, and achieve fast and convenient assembly and use Reliable and reduce labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

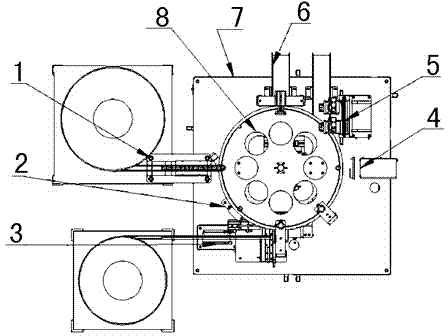

[0010] Depend on figure 1 Known, the guide rod rubber bush automatic assembly machine consists of guide rod automatic feeding mechanism 1, automatic oiling mechanism 2, rubber bush automatic feeding and fitting mechanism 3, visual inspection mechanism 4, unqualified product unloading mechanism 5 mechanisms, Qualified product blanking mechanism 6, frame 7 and guide rod feeding turntable transmission mechanism 8 are formed, and the frame is provided with guide rod automatic feeding mechanism 1, automatic oiling mechanism 2, rubber The bushing automatic feeding and fitting mechanism 3, the visual inspection mechanism 4, the unqualified product unloading mechanism 5 and the qualified product unloading mechanism 6, are characterized in that: the discharge port of the guide rod automatic feeding mechanism 1 is fixed on The feeding turntable on the frame 7 is docked, and the feeding turntable is not connected to the rubber sleeve feeding and fitting mechanism 3. The feeding turntable...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com