A kind of x8r type fine-grained ceramic capacitor dielectric material and preparation method thereof

A technology of ceramic capacitors and capacitor dielectrics, applied in the direction of piezoelectric/electrostrictive/magnetostrictive devices, circuits, electrical components, etc., can solve the unfavorable development of MLCC ultra-thin layers, large powder particles and ceramic grains, Long preparation process route and other problems, to achieve the effect of small temperature change rate, small dielectric loss and good dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] Its preparation method comprises the following steps:

[0029] (1) At a water bath temperature of 30-50 °C, a certain amount of TiCl 4 Slowly add the solution dropwise into 6~10 mol / L NaOH solution, and stir thoroughly for 0.5~1 h;

[0030] (2) Slowly add the prepared aqueous solution of bismuth and barium ions according to the stoichiometric ratio, and keep stirring. The reaction temperature is 30~50 ℃, and the reaction time is 0.5~1 h;

[0031] (3) Continue stirring the above solution for 2-6 h at a water bath temperature of 75-95 °C, wash and dry to obtain Ba 1- x Bi x TiO 3 Powder;

[0032] (4) The Ba of step (3) 1-x Bi x TiO 3 The powder is ultrasonically dispersed in deionized water to obtain Ba with good dispersibility 1- x Bi x TiO 3 suspension;

[0033] (5) mixing the niobium oxalate solution and the cobalt nitrate solution according to the ratio of substances to obtain a clear mixed solution of inorganic salts;

[0034] (6) Slowly add the mixed so...

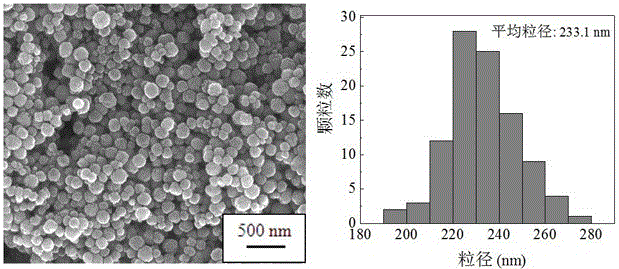

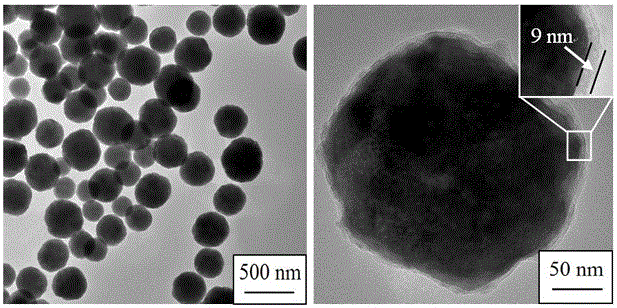

Embodiment 1

[0039] Preparation of Ba 1-x Bi x TiO 3 @(Nb 2 o 5 -Co 3 o 4 ) powder and its ceramic materials, wherein, Ba 1-x Bi x TiO 3 + n(aNb 2 o 5 + bCo 3 o 4 ) in x=0.010, a:b=3:1; n are 0.004, 0.008, 0.012 and 0.016 respectively (the serial numbers of corresponding samples are recorded as #1-1, #1-2, #1-3 and #1- 4). Promptly adopt the liquid phase coating method of the present invention to prepare Ba 0.99 Bi 0.01 TiO 3 + n(3 mol% Nb 2 o 5 + 1 mol% Co 3 o 4 ) The specific steps of the powder and its ceramic dielectric material are as follows:

[0040] (1) At a water bath temperature of 30 °C, 50.00 mL of 0.2014 g / mL TiCl 4 The solution was slowly added dropwise into 100.00 mL of 10.0 mol / L NaOH solution, and fully stirred for 0.5 h, then slowly added bismuth and barium aqueous solutions to the above solution according to the stoichiometric ratio, and kept stirring for 0.5 h, and then the above The solution was stirred for 4 h in a water bath at a temperature o...

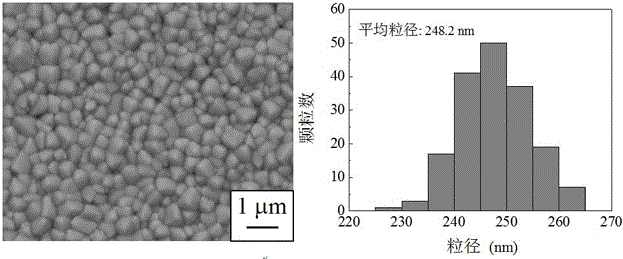

Embodiment 2

[0049] Adopt the liquid phase coating method technique of the present invention to prepare Ba 1-x Bi x TiO 3 @(Nb 2 o 5 -Co 3 o 4 ) powder and its ceramic materials, wherein, Ba 1-x Bi x TiO 3 + n(aNb 2 o 5 + bCo 3 o 4 ) where x=0.010 and n=0.012; a:b are 6:1, 4.5:1, 3:1 and 1.5:1 respectively (the serial numbers of corresponding samples are recorded as #2-1, #2-2, #2 in turn -3 and #2-4). i.e. prepared Ba 0.99 Bi 0.01 TiO 3 + 0.012×(aNb 2 o 5 + bCo 3 o 4 ) The specific steps of the powder and its ceramic dielectric material are as follows:

[0050] (1) At a water bath temperature of 30 °C, 50.00 mL of 0.2014 g / mL TiCl 4 The solution was slowly added dropwise into 100.00 mL of 10.0 mol / L NaOH solution, and fully stirred for 0.5 h, then slowly added bismuth and barium aqueous solutions to the above solution according to the stoichiometric ratio, and kept stirring for 0.5 h, and then the above The solution was stirred for 4 h in a water bath at a tempera...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com