Wear-resistant and fireproof wood-plastic floor and preparation method thereof

A technology for wood-plastic flooring and equipment, which is applied to buildings, building structures, floors, etc., can solve the problems of fire-resistant floors without fire protection, fire-resistant floors with great use, and troublesome production, and achieves reasonable production methods and ratios. Clear, product wear-resistant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to make the technical means, creative features, objectives and effects achieved by the present invention easy to understand, the present invention will be further elaborated below.

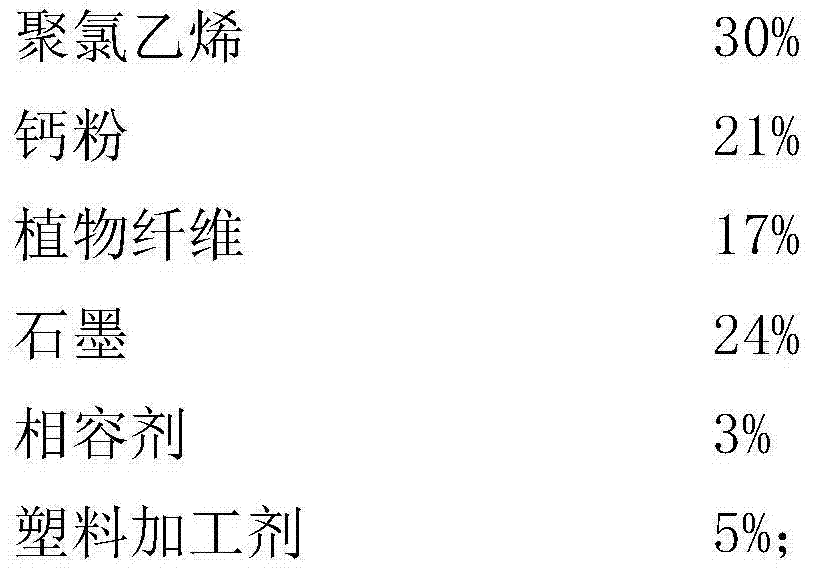

[0022] A wear-resistant, fire-resistant wood-plastic floor, characterized in that: the optimal composition is,

[0023]

[0024] A method for preparing a wear-resistant and fireproof wood-plastic floor, characterized in that it comprises the following steps,

[0025] Step 1. Put polyvinyl chloride, plant fiber, and graphite materials into a pulverizer to pulverize them into granules, and then put them into a sealed storage box;

[0026] Step 2, put the pulverized materials in step 1 into the agitator according to the order of plant fiber, polyvinyl chloride, and graphite, and put in a material every 5 minutes, and put in a compatibilizer while putting in the material, and stir for 10 minutes. After 2 minutes, add calcium powder and continue to stir for 7 minutes;

[0027] Step...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com