Heat dissipation material for air cooling tubes and preparation method thereof

A heat dissipation material and air-cooling technology, which is applied in the manufacture of aluminum-steel composite materials and the field of aluminum-steel composite materials for air-cooled heat dissipation pipes, can solve the problems of complex brazing processing, high melting point of steel strip materials, and high requirements for welding operations, so as to save energy , reduce the brazing temperature, improve the effect of economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

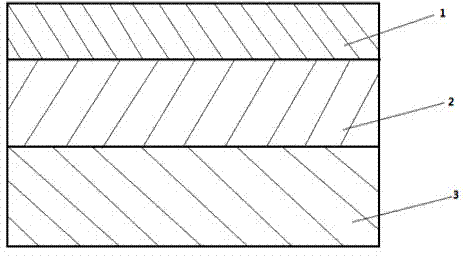

[0022] The structure of a kind of air cooling radiating pipe material of the present invention is as follows: figure 1 As shown, it includes a brazing layer 1, a heat conduction layer 2 and a substrate 3. The brazing layer 1 is located on one side of the substrate, and a heat conduction layer 2 is provided between the brazing layer 1 and the substrate. The welding layer is composed of the following materials by weight percentage: Si: 7.6, Fe: 0.05, Cu: 0.06, Mn: 0.04, Zn: 0.05, the total amount of remaining impurities is 0.15, and the balance is aluminum. The heat conduction layer 2 is composed of the following materials by weight percentage Composition: Si: 0.815, Fe: 0.443, Cu: 0.002, Mn: 0.01, Mg: 0.002, Zn: 0.011, Zr: 0.003, Ti: 0.001, the total amount of remaining impurities is 0.15, and the balance is aluminum. The base material 3 is composed of the following Material composition in weight percent: C: 0.006, Si: 0.004, Mn: 0.24, P: 0.016, S: 0.006, Cu: 0.02, Sn: 0.002, t...

Embodiment 2

[0043] Such as figure 1 As shown, an air-cooled heat pipe material of the present invention includes a brazing layer 1, a heat conduction layer 2 and a base material 3, the brazing layer 1 is located on one side of the base material, and the brazing layer 1 and the base material There is a heat conduction layer 2 between the materials, and the brazing layer is composed of the following materials in weight percentage: Si: 7.7, Fe: 0.03, Cu: 0.04, Mn: 0.05, Zn: 0.06, the total amount of remaining impurities is 0.15, and the balance is aluminum , the heat conduction layer 2 is composed of the following materials in weight percentage: Si: 0.83, Fe: 0.45, Cu: 0.008, Mn: 0.02, Mg: 0.005, Zn: 0.015, Zr: 0.001, Ti: 0.002, and the total amount of remaining impurities is 0.15, The balance is aluminum, and the substrate 3 is composed of the following materials in weight percentage: C: 0.007, Si: 0.004, Mn: 0.2, P: 0.013, S: 0.002, Cu: 0.03, Sn: 0.005, and the total amount of remaining im...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com