Negative pressure guide capturing type smooth and clean spinning device

A soft and smooth technology, applied in the field of textile processing, can solve the problems of reducing the fiber utilization rate of ring spinning, the quality of the finished yarn cannot be improved, and the adhesion force is weak, so as to eliminate the surface hairiness of the yarn body and save Production cost and the effect of improving yarn quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] In the cotton fiber siro spinning process, the yarn quality of ring spinning is improved.

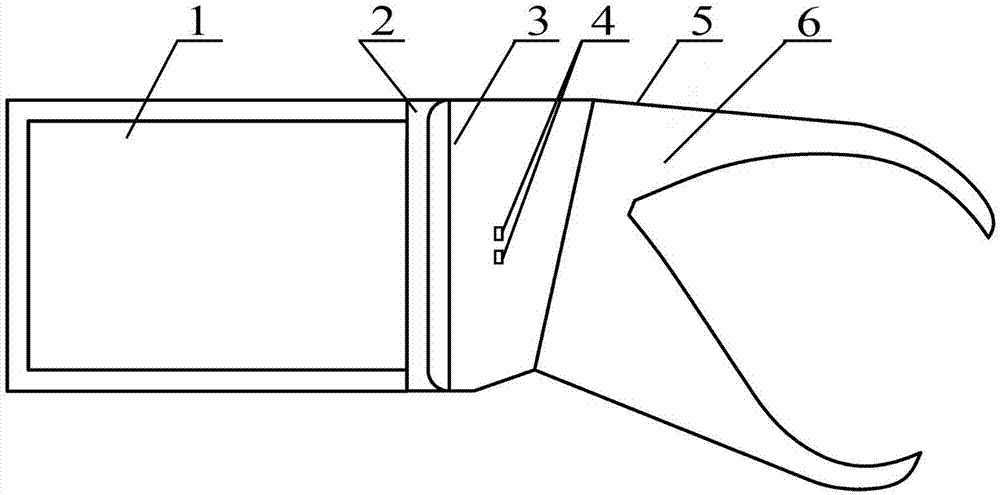

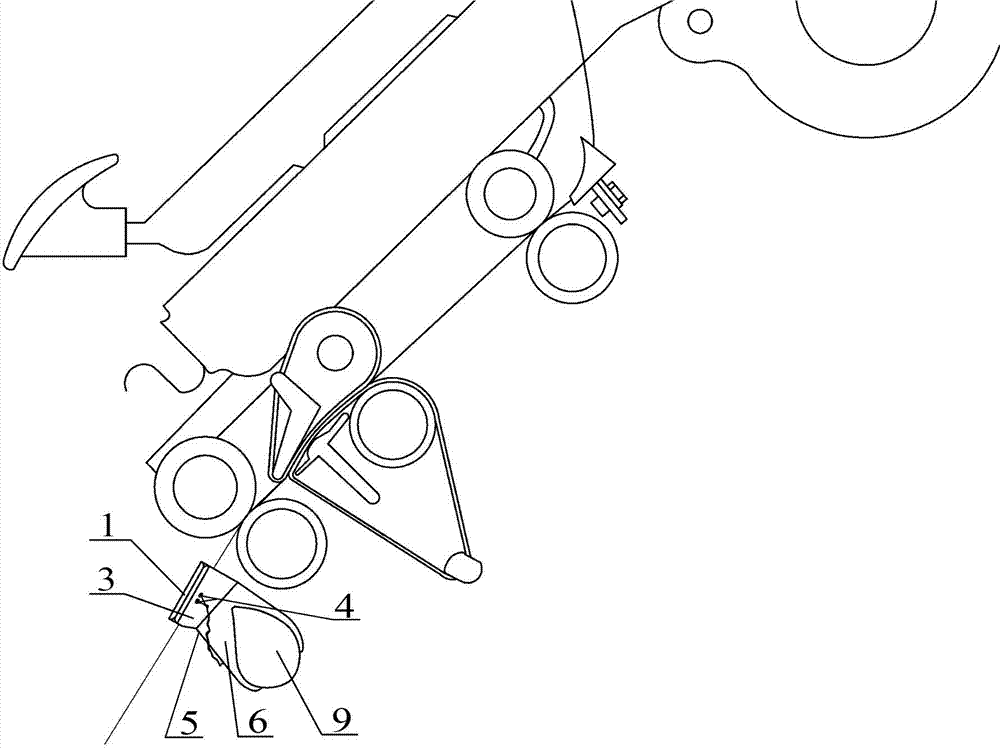

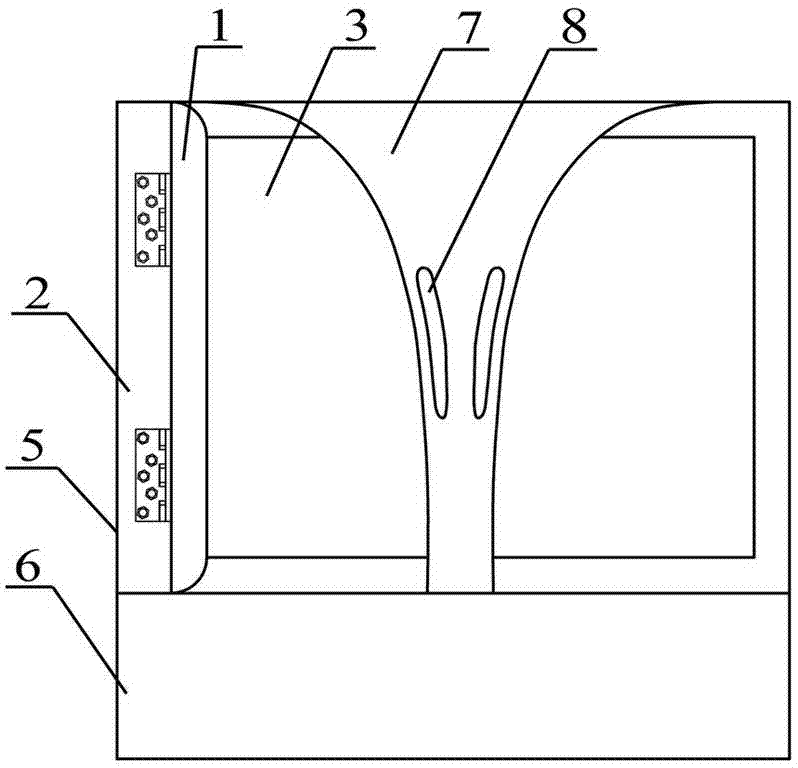

[0022] On the cotton-type ring spinning frame, the negative pressure guiding and catching device is fixedly installed on the pear-shaped suction bagpipe 9 through the base 6, and connected to the suction pipe 9 and the suction channel in the heating part 3. The tuyere 8 generates a negative pressure airflow in the holding groove 7, and the two cotton rovings enter a drafting system of the ring spinning frame through a double bell mouth feeder with a distance of 4 mm. Roller and front roller are output by the front roller nip, and the output two whiskers are converged and twisted into yarn, and the twisted composite yarn immediately enters the holding groove 7 of the heating part 3, and the grip at the air suction port 8 The ratio of the width of the holding groove 7 to the width of the outlet of the holding groove 7 is 1.5-2.0, and the negative pressure airflow in the holding gro...

Embodiment 2

[0024] Improve the yarn quality of ring spinning in wool siro core-spun compound spinning process.

[0025] On the wool-type ring spinning frame, cancel the wool-type single-pipe suction pipe system per spindle, and refit it into a pear-shaped suction pipe 9 for cotton spinning, and the negative pressure guiding and catching device is fixedly installed on the suction pipe 9 through the base 6 on, and connect the suction bagpipe pipe 9 with the suction passage in the heating part 3, and the two wool rovings enter a drafting system of the wool-type ring spinning frame through a double bell-mouth feeder with a distance of 6 mm, and are drawn After drafting by the stretching system, it is output from the front roller nip composed of the front rubber roller and the front roller. The polyester filament unwound from the filament package is output from the rear of the front rubber roller through the front roller nip through the wire guide device. It is located in the middle of the lef...

Embodiment 3

[0027] Improve the forming quality of ramie single yarn in the process of ramie long fiber ring spinning.

[0028] On the ring spinning frame of long hemp spinning, cancel the single-tube suction pipe system of each spindle of long hemp spinning, and refit it into a pear-shaped suction pipe 9 for cotton spinning, and the negative pressure guiding and catching device is fixedly installed on the suction pipe 9 through the base 6 and connect the suction bagpipe pipe 9 with the suction passage in the heating part 3, a ramie roving enters a drafting system of the wool-type ring spinning frame through the feeding horn, after being drafted by the drafting system, it is drawn from The front roller nip output by the front rubber roller and the front roller, the ramie strands output by the front roller nip are twisted into a composite yarn under the action of twisting, and the twisted composite yarn immediately enters the grip of the heating part 3 In the groove 7, the ratio of the widt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com