Oil tank for hydraulic mechanism

A hydraulic mechanism and oil tank technology, applied in the field of hydraulic systems, can solve problems such as unfavorable hydraulic mechanism normal power, affecting oil flow and heat dissipation effect, insufficient oil heat dissipation distance, etc., achieving good application prospects, ensuring normal power output, The effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings.

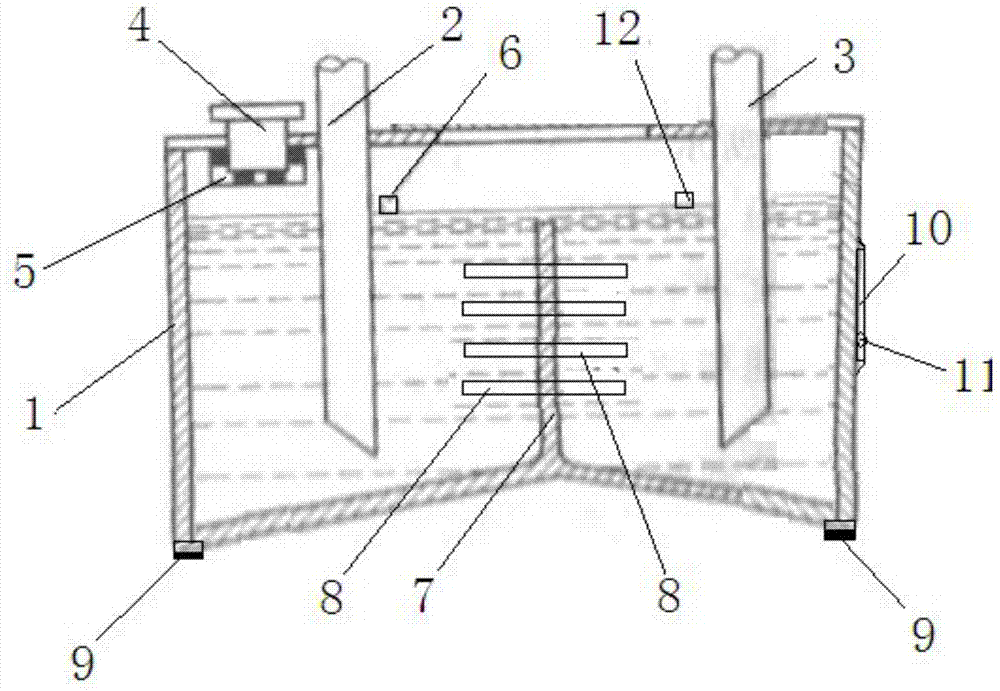

[0016] Such as figure 1 As shown, a fuel tank for a hydraulic mechanism is characterized in that it includes a fuel tank body 1, and the bottom of the fuel tank body 1 is in a concave isosceles triangle shape, which can increase the flow tendency of liquid oil. There are oil inlet pipe 2 and oil outlet pipe 3 arranged in parallel, the upper part of oil inlet pipe 2 and oil outlet pipe 3 extends out of the upper surface of oil tank body 1, oil inlet pipe 2 is connected with the oil outlet end of the hydraulic mechanism, and oil outlet pipe 3 is connected with the oil outlet of the hydraulic mechanism. The oil inlet ends are connected, and the upper surface of the fuel tank body 1 is provided with a ventilating filling port 4, and the end of the venting filling port located in the fuel tank body 1 is provided with a filter screen 5, and the fuel tank body 1 is also provi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com