Safety valve for multi-way valve

A technology of safety valve and multi-way valve, which is applied in the direction of fluid pressure actuation system safety, fluid pressure actuation device, mechanical equipment, etc. It can solve the problems of light load lifting, insufficient oil pressure, heavy load cannot be lifted, etc., to reduce Effects of replacement times, increased service life, and reduced abrasive wear and torsional damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will now be further described in conjunction with specific examples, and the following examples are intended to illustrate the present invention rather than further limit the present invention.

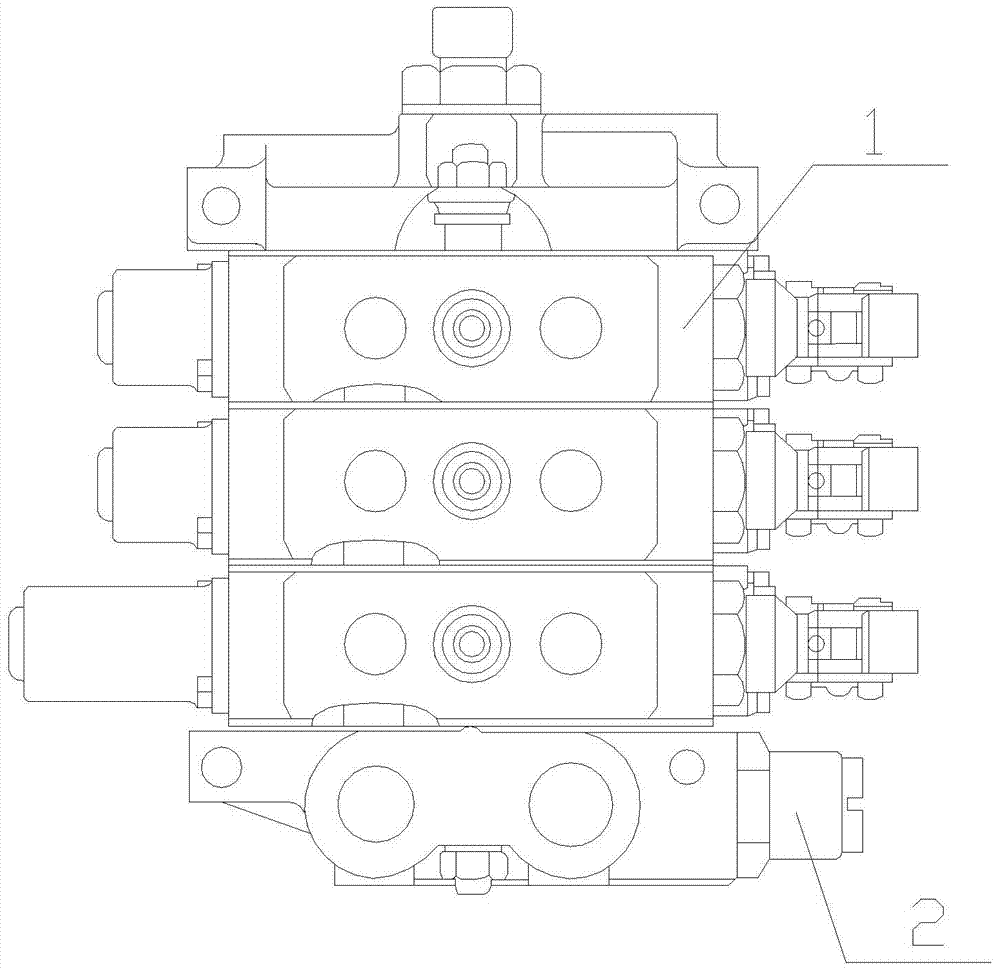

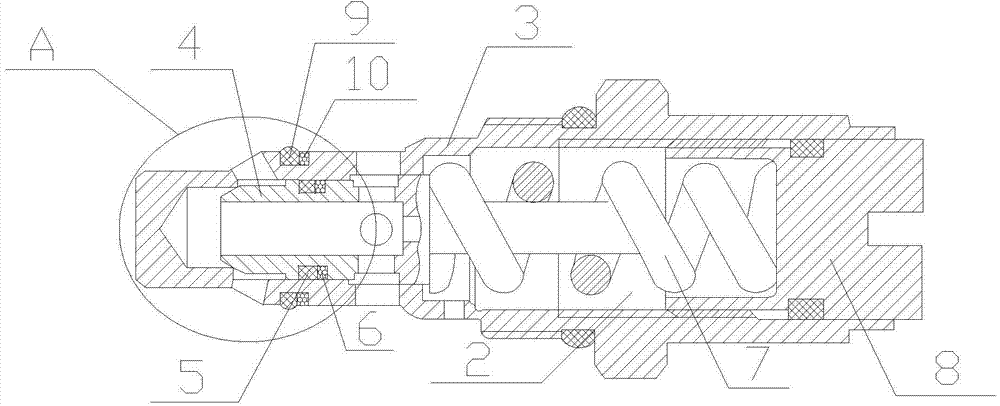

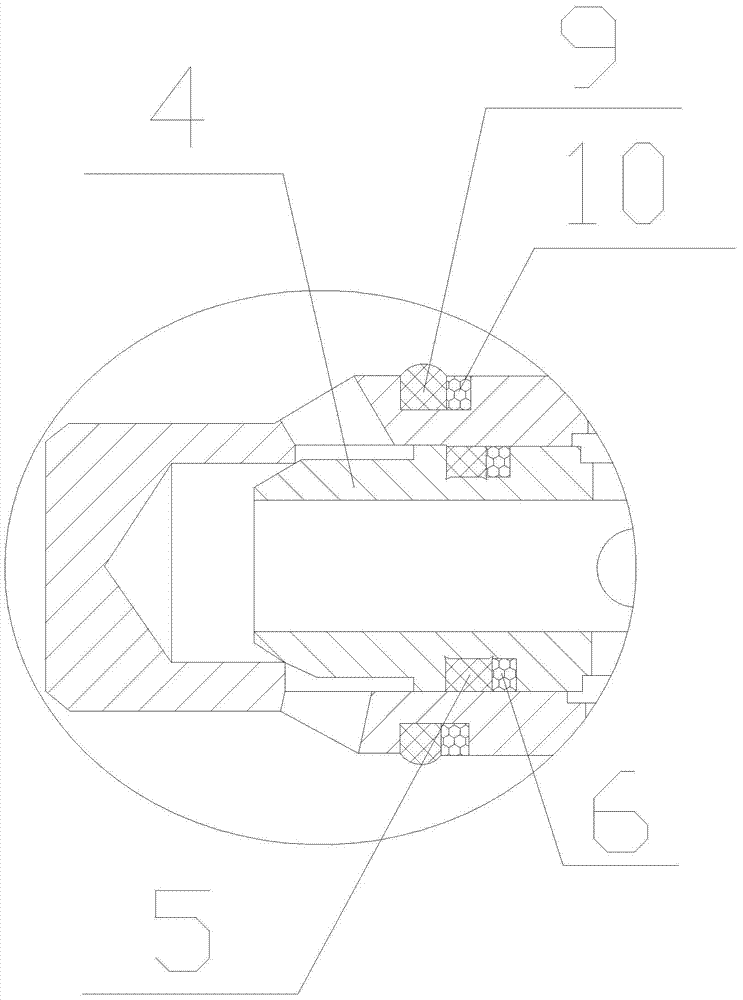

[0016] Such as figure 1 As shown, a safety valve for a multi-way valve includes a safety valve assembly 2 installed on the front cover of the multi-way valve 1, such as Figure 2~3 As shown, the safety valve assembly 2 includes a valve body 3, a valve core 4 is installed in the valve body 3, and a seal installation groove is provided on the outer surface of the valve core 4, and the installation groove is formed by the high-pressure area where the first O-ring 5 is placed. The groove is composed of the groove in the low pressure area of the first servo washer 6, and the groove in the high pressure area has a "eight" shaped groove bottom.

[0017] The seal installation groove is divided into the high-pressure zone groove for the first O-ring 5 and the lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com