A flow-through fluorescence detection cell

A fluorescence detection and detection cell technology, applied in the field of fluorescence detectors, can solve problems such as high background noise of detection cells, and achieve the effects of reducing high background noise, wide inner diameter range, and simple device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

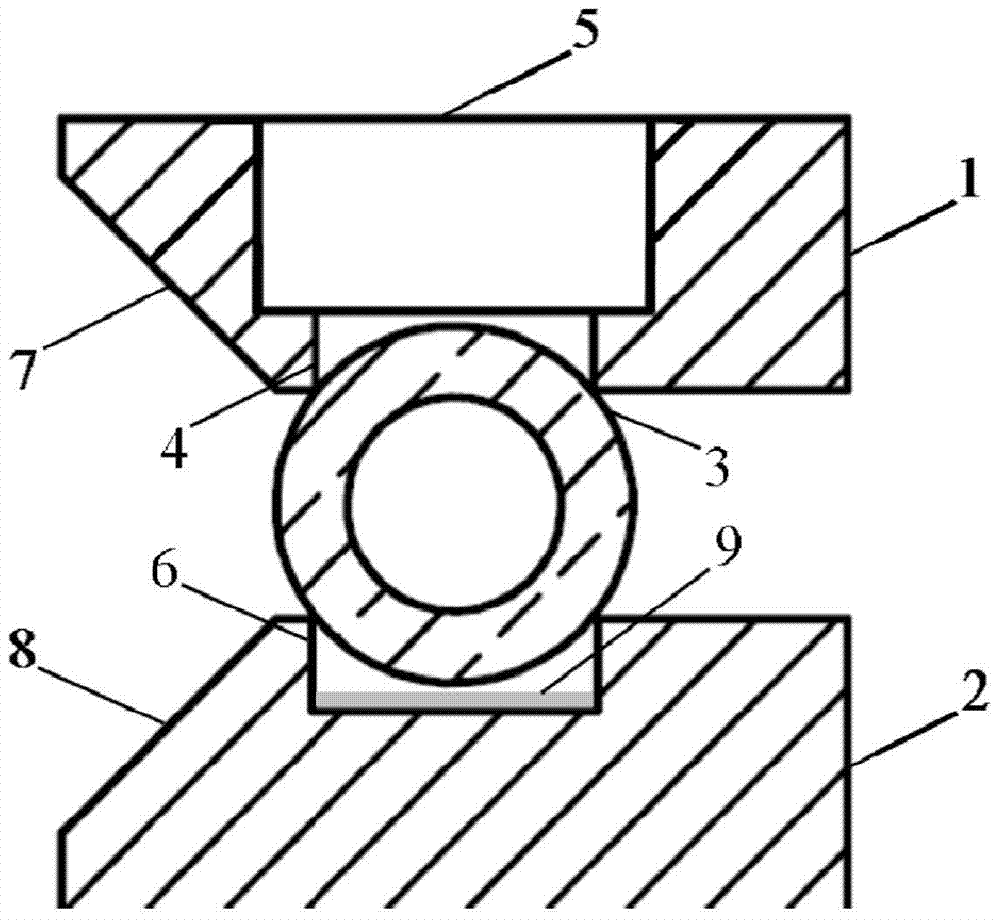

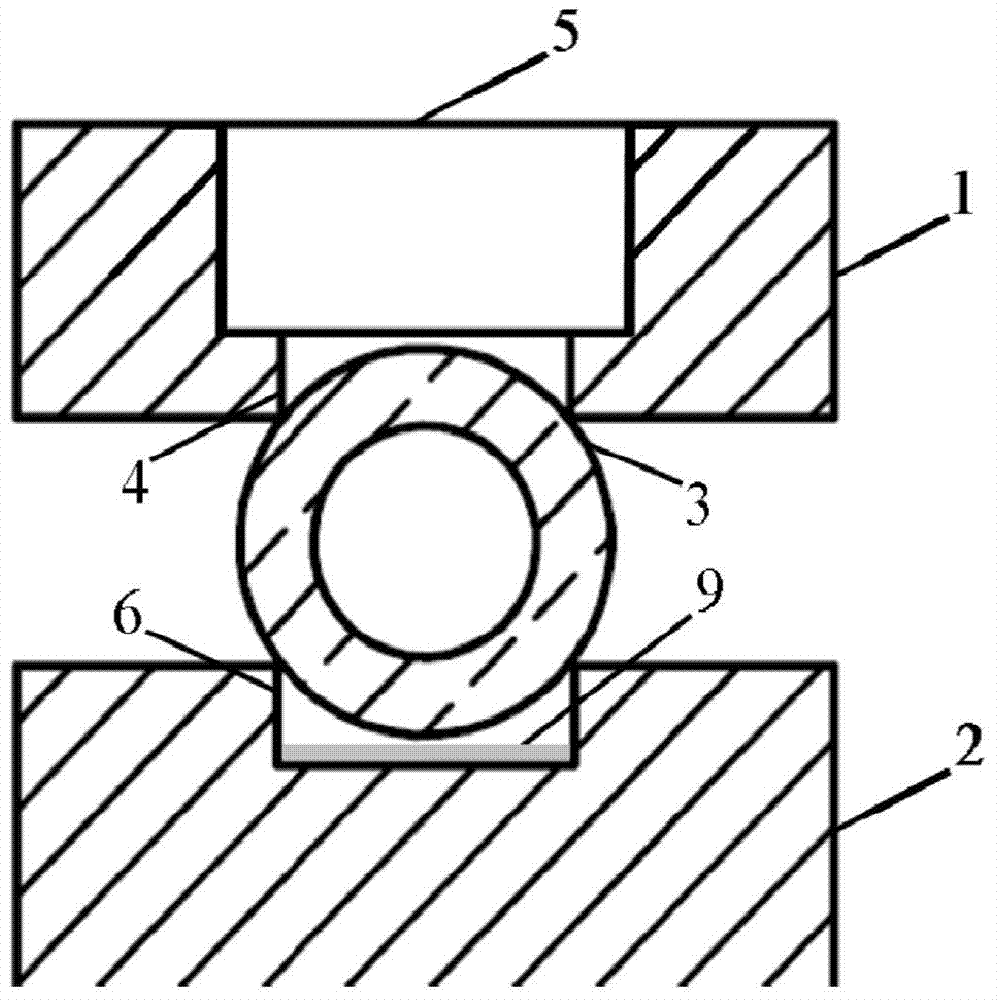

[0034] A flow-through fluorescent detection cell, the cross-sectional view is as follows figure 1As shown, it consists of an upper clamp 1, a lower clamp 2 and a cylindrical quartz tube 3. The upper clamp 1 and the lower clamp 2 are oxidized and blackened aluminum materials. The upper clamp 1 is a cylindrical structure, and the lower end surface is provided with a through rectangular upper groove 4; at the bottom of the rectangular upper groove 4, the upper end surface of the clamp 1 is vertically upwardly provided with a through hole as a light hole 5, The depth of the light hole 5 reaches the bottom of the upper groove 4; the lower clamp 3 is a cylindrical structure, and the top is provided with a rectangular lower groove 6; the bottom of the lower groove 6 is provided with a reflector 9, and the reflector 9 is aluminum membrane. The quartz tube 3 has an inner diameter of 3 mm and an outer diameter of 5 mm, and is clamped between the upper groove 4 and the lower groove 6 a...

Embodiment 2

[0042] For the fluorescence detection cell described in Example 1, the excitation optical path is changed to an excitation optical fiber with a core diameter of 5 mm, the excitation optical fiber is inserted into the light hole 5, and the emitted light is irradiated onto the quartz tube 3 through the excitation optical fiber. The fluorescence collection optical path is changed to a 3mm fluorescence collection optical fiber; the fluorescence collection optical fiber is inserted into the gap between the upper clamp 1 and the lower clamp 2, and its axis is perpendicular to the axis of the quartz tube 3; both the excitation optical fiber and the fluorescence collection optical fiber are physically connected to the quartz tube touch.

[0043] The experimental results are: Compared with the existing close-fitting detection pool (Talanta, 2012, 88, 463-467), the detection signal-to-noise ratio is increased by 2.5 times.

Embodiment 3

[0045] Fluorescence detection cell as described in Example 1, wherein the quartz tube 3 is changed to a quartz capillary with an inner diameter of 50 microns and an outer diameter of 365 microns; the width of the upper groove 4 and the lower groove 6 is 0.2 mm, and the depth is 0.1 mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com