Working height adjusting and control system and method for rotary tillage tool of rotary cultivator

A technology of adjusting control and working height, applied in the fields of farming equipment, agricultural machinery and equipment, application, etc., can solve the problems of engine overload operation, time-consuming, troublesome operation, etc., to prolong the service life of machinery, avoid overload work, reduce The effect of the number of times of re-cultivation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

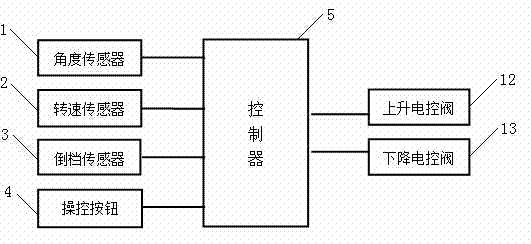

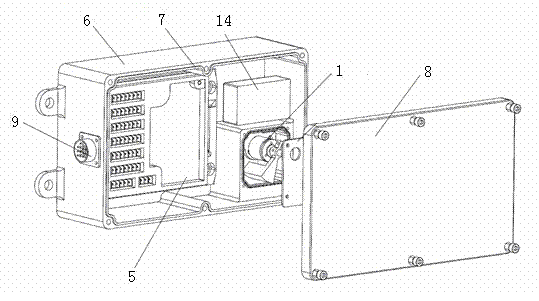

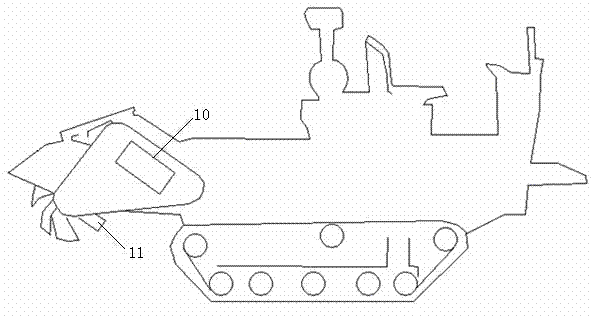

[0027] refer to Figure 1-Figure 3 , the working height adjustment control system of the rotary tiller cutter of the present embodiment includes a control box 10, an angle sensor 1, a rotational speed sensor 2, a reverse gear sensor 3 and a control button 4; the control box 10 includes a casing 6, a waterproof ring 7. Housing cover 8, controller 5 and signal cable connector 9, the controller 5 is installed in the housing 6, the signal cable connector 9 is installed on the housing 6, the signal cable connector 9 is connected to the controller 5, the housing cover 8 is connected to the housing 6 through the waterproof ring 7; the angle sensor 1 is installed in the control box 10, and the control box 10 is installed on the side of the rotary tiller cutter 11, and the angle sensor 1 Connect to the controller 5 through the signal cable connector 9; the rota...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com