Suspension lifting system of broadside wire-laminated micro-spraying hose

A technology of lifting system and micro-spraying belt, which is applied in portable lifting devices, horticultural, botanical equipment and methods, etc., can solve the problem of reducing the uniformity of irrigation water distribution, changing the angle of spraying water flow, spraying width and spraying uniformity, etc. problems, to achieve the effect of reducing the operation links of pulling steel wires and hanging, the facility occupies a small space, and reduces labor input

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0031] This specific embodiment is only an explanation of the present invention, not a limitation of the present invention. After reading this specification, those skilled in the art can make modifications to this embodiment without creative contribution as required, but as long as they are within the rights of the present invention All claims are protected by patent law.

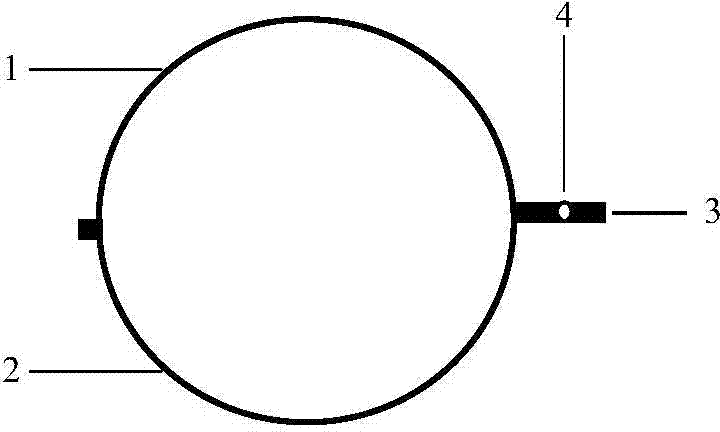

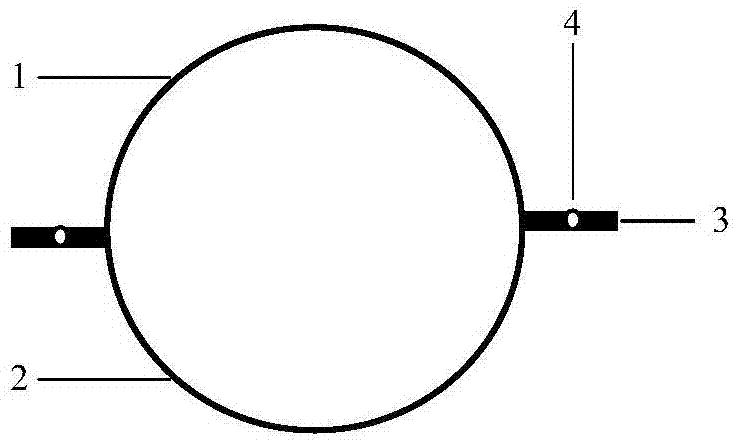

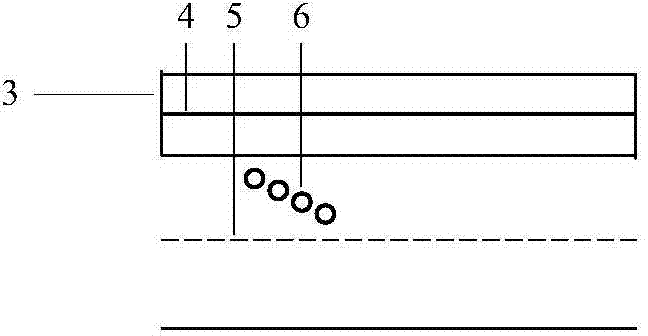

[0032] Examples see attached figure 1 , 2 , 3, 4, a kind of wide-edge wire-embedded micro-spray tape, comprising upper tape sheet (1) and lower tape sheet (2), two tape sheets form a width of 8mm on one side or both sides during the bonding process. Side (3), steel wire (4) is embedded in the wide side; a rolling system can also be used to add steel wire in a molten state on both edges of the upper strip and the lower strip, and roll out one side or two sides embedded with steel wire. b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com