Liquid level monitoring and automatic stirring device for lithium ion battery coating slurry

A lithium-ion battery and liquid level monitoring technology, which is applied to devices and coatings for coating liquid on the surface, can solve the problems of high labor costs, overflowing slurry, and high slurry liquid level, and achieves improved coating consistency, The effect of reducing labor costs and stabilizing the slurry level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

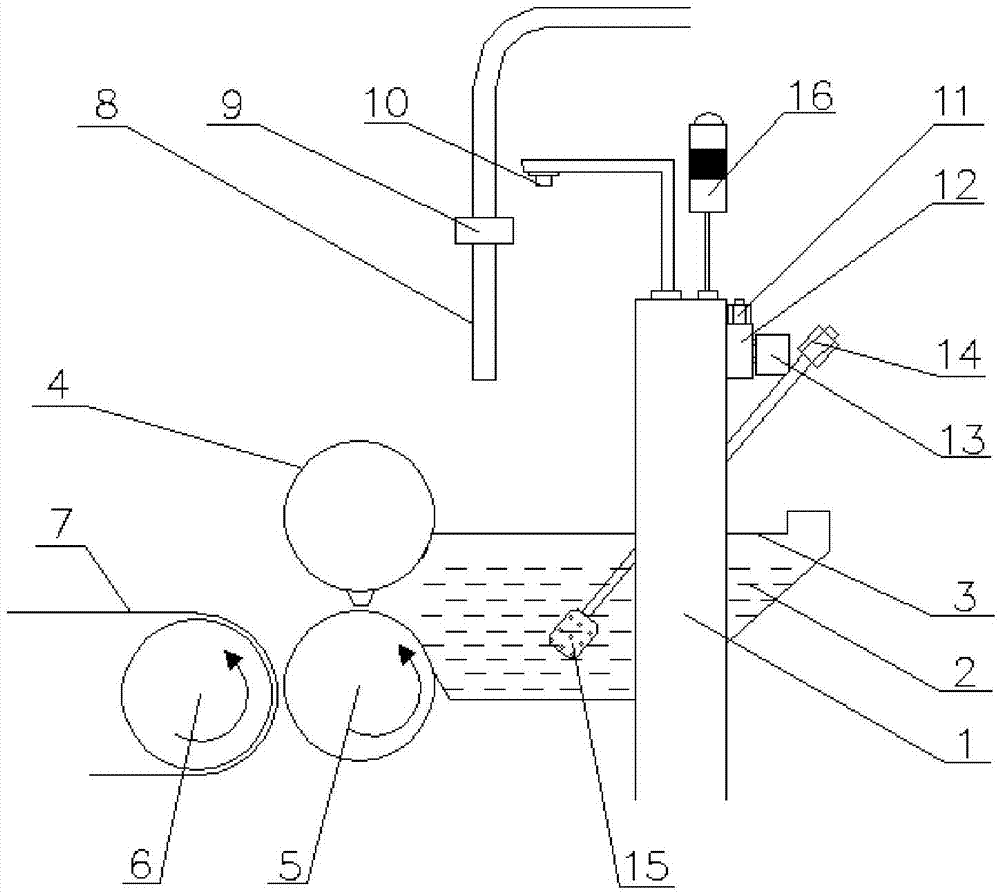

[0014] Such as figure 1 As shown, a lithium-ion battery coating slurry liquid level monitoring and automatic stirring device, the material tank 3 is fixed on the coating machine frame 1, the slurry 2 is housed in the material tank 3, and the material tank 3 One side passes through the knife roller 4, the coating roller 5 and the back roller 6 to complete the coating of the slurry 2 on the surface of the foil 7 to form a coating mechanism for coating, and the liquid level sensor 10 is installed on the coating machine frame 1 through a “” type bracket The left side of the upper end is vertically suspended above the liquid surface of the slurry 2 for monitoring to form a liquid level sensing mechanism for liquid level detection and sensing, and the slurry delivery pipeline 8 is vertically arranged above the material tank 3 to form a feed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com