Starch stirring and sorting device for processing and production

A sorting device, starch technology, applied in biological packaging, sustainable manufacturing/processing, solid separation, etc., can solve the problems of starch splashing, starch caking, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

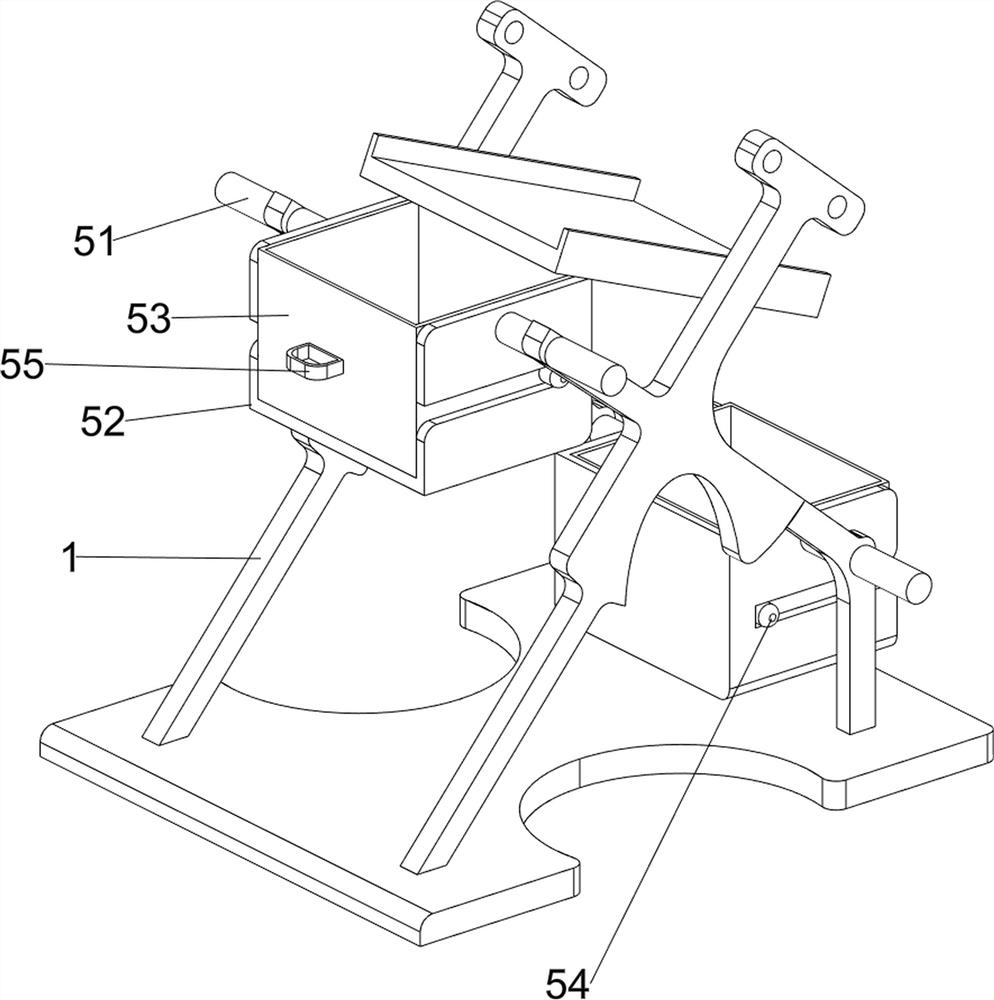

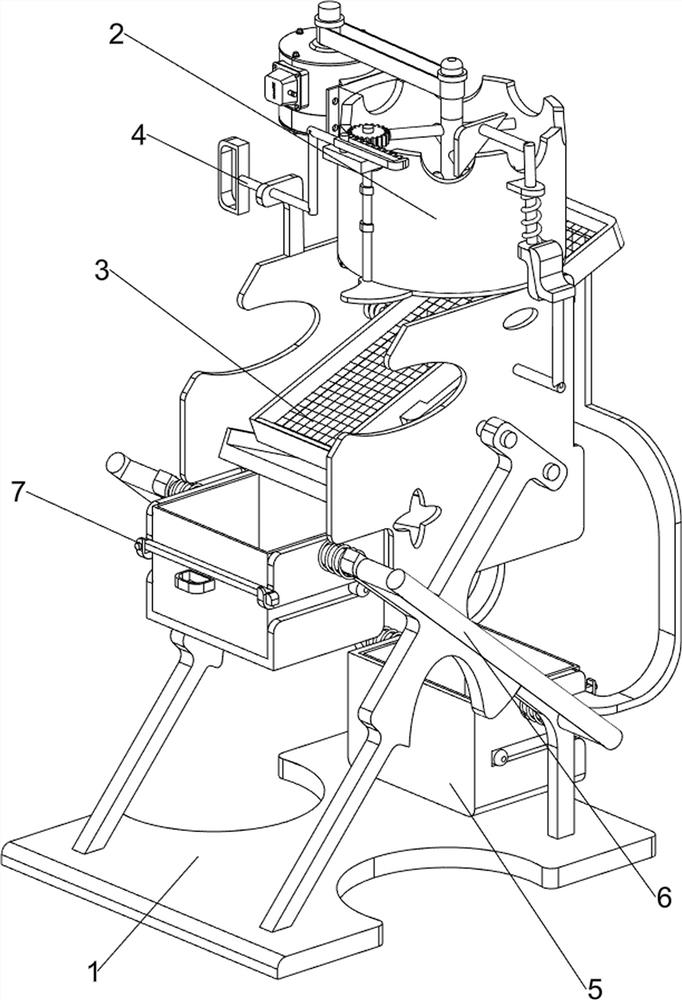

[0064] A starch stirring and sorting device for processing and production, such as figure 1 As shown, it includes a bottom plate 1 , a stirring mechanism 2 and a sorting mechanism 3 , the bottom plate 1 is provided with the stirring mechanism 2 , and the bottom plate 1 and the stirring mechanism 2 are provided with the sorting mechanism 3 .

[0065] When people need to sort the starch, they can first pour the starch into the stirring mechanism 2, place the collection frame on the bottom plate 1, and then start the stirring mechanism 2, so that the stirring mechanism 2 can stir the starch, and pass through the sorting mechanism 3 Sorting is carried out, qualified starch falls into the collection frame, and granular starch is left on the sorting mechanism 3, and the stirring mechanism 2 can be closed when not in use.

Embodiment 2

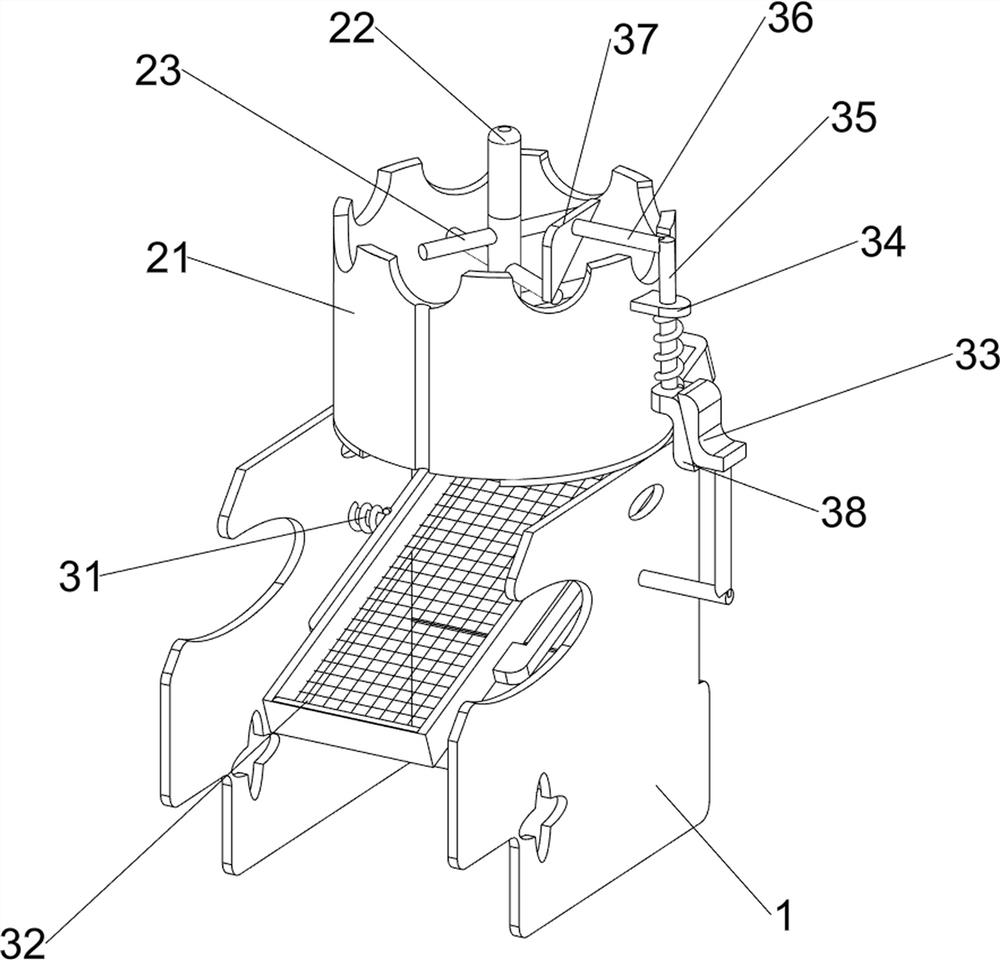

[0067] On the basis of Example 1, such as Figure 2-8 As shown, the mixing mechanism 2 includes a mixing bucket 21, a first rotating shaft 22, a stirring rod 23, a motor fixing plate 24, a servo motor 25 and a rotating assembly 26. The top of the bottom plate 1 is provided with a mixing bucket 21, and the mixing bucket 21 is connected in a rotating manner. A first rotating shaft 22 is arranged, and a stirring rod 23 is evenly arranged on the first rotating shaft 22, a motor fixing plate 24 is arranged on the left side of the mixing bucket 21, a servo motor 25 is arranged on the motor fixing plate 24, and the output shaft of the servo motor 25 is connected with the first rotating shaft A rotating assembly 26 is provided between the 22 tops.

[0068] When people need to sort the starch, they can first pour the starch into the mixing tank 21, start the servo motor 25, and the rotation of the output shaft of the servo motor 25 drives the rotating assembly 26, the first rotating sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com