Aluminum coil stamping automation equipment and stamping method

A technology of automation equipment and aluminum coils, which is applied in metal processing equipment, forming tools, feeding devices, etc., can solve the problems of unguaranteed product quality, affecting processing efficiency, and reducing feeding speed, so as to ensure the quality of follow-up production, Improve spraying efficiency and reduce manual effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

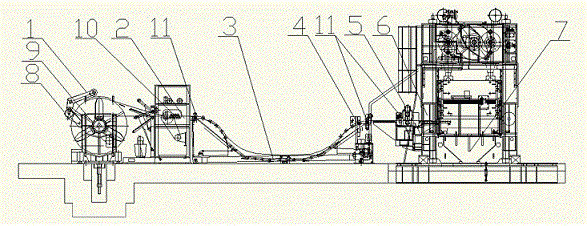

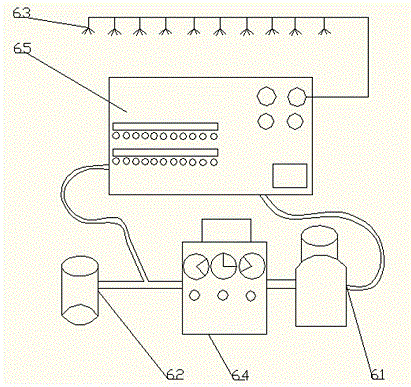

[0039] A kind of aluminum stamping automation equipment described in the present invention, as attached figure 1 As shown, it includes an uncoiling mechanism 1, a leveling mechanism 2, a feeding mechanism 5, an oil injection mechanism 6 and a machine tool 7 arranged in sequence. The uncoiling mechanism 1 includes a servo motor 8 and a roller 9 connected to each other; the feeding mechanism 5 includes a second servo motor and a feed roller 11 connected to each other, the feeding mechanism 5 gap feeds and the gap time and feeding speed are synchronized with the stamping frequency of the machine tool 7; the uncoiling mechanism 1 and the feeding mechanism 5 A deceleration device is also provided respectively, and the deceleration device is used to reduce the starting speed of the uncoiling mechanism 1 and the feeding mechanism 5, so as to prevent the deformation of the aluminum coil due to the sudden increase of the pulling force caused by the excessive starting speed.

[0040] At...

Embodiment 2

[0068] The overall structure of this embodiment is the same as that of Embodiment 1, and the difference is that: the whole device is not provided with the lifting and conveying mechanism 4, and the height of the uncoiling mechanism 1 and the leveling mechanism 2 is higher than that of the feeding mechanism 5, And a material buffer zone 3 is arranged between the leveling mechanism 2 and the feeding mechanism 5, because the height of the aluminum coil in the leveling mechanism 2 is higher than the height of the aluminum coil in the described feeding mechanism 5, the aluminum coil is in the A decreasing arc is formed in the area of material buffer zone 3; the working process of this embodiment is generally consistent with that of embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com