Multi-axis and multi-station independent automatic screw locking machine

An automatic locking screw machine, multi-station technology, used in metal processing, manufacturing tools, metal processing equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

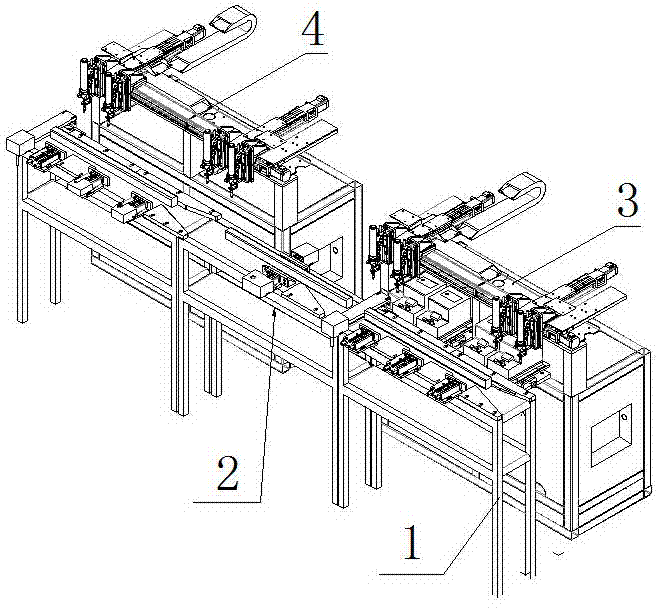

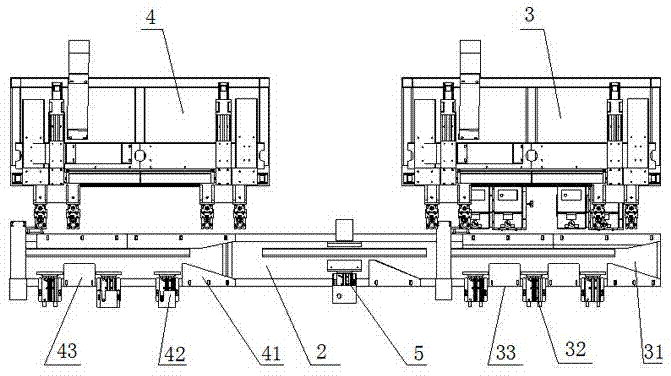

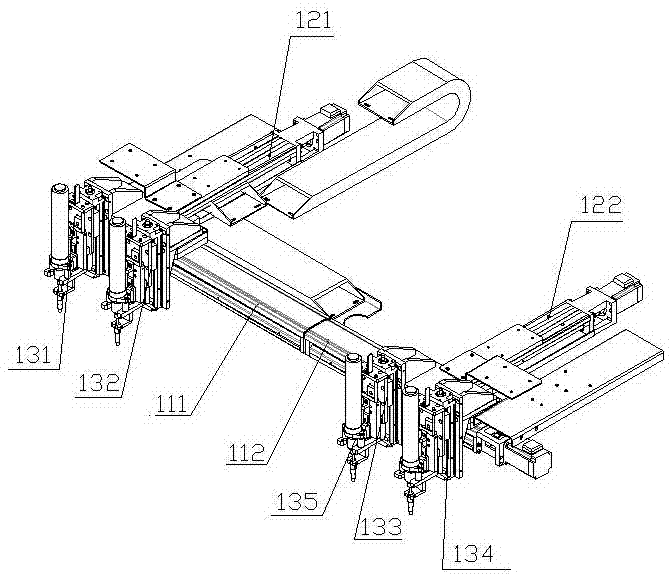

[0015] In this example, if Figure 1 to Figure 3 As shown, a multi-axis multi-station independent automatic screw locking machine of the present invention includes a workbench 1, an assembly line 2 arranged at the top and front end of the workbench 1, and a first processing mechanism 3 arranged behind the assembly line 2, and The second processing mechanism 4 arranged on the left side of the first processing mechanism 3; the first processing mechanism 3 and the second processing mechanism 4 can be provided with more than one; each of the assembly line 2 at the front end of the first processing mechanism 3 All are provided with the first guiding mechanism 31, and the first positioning mechanism 32 that is arranged on the left side of the first guiding mechanism 31, described first positioning mechanism 32 is provided with more than three, between every two described first positioning mechanisms 32 A first limit mechanism 33 is provided.

[0016] The assembly line 2 at the fron...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com