Fast positioning device applied to automatic feeding drill

A technology of automatic feed drilling and positioning device, which is applied in the direction of positioning measurement in boring machine/drilling machine, components of boring machine/drilling machine, drilling/drilling equipment, etc., which can solve the problem of increasing hole preparation time and reducing automatic feed drilling. Problems such as the overall hole-making efficiency of the equipment, to achieve the effect of reducing manual intervention and strong versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention will be further described in detail below in conjunction with the accompanying drawings.

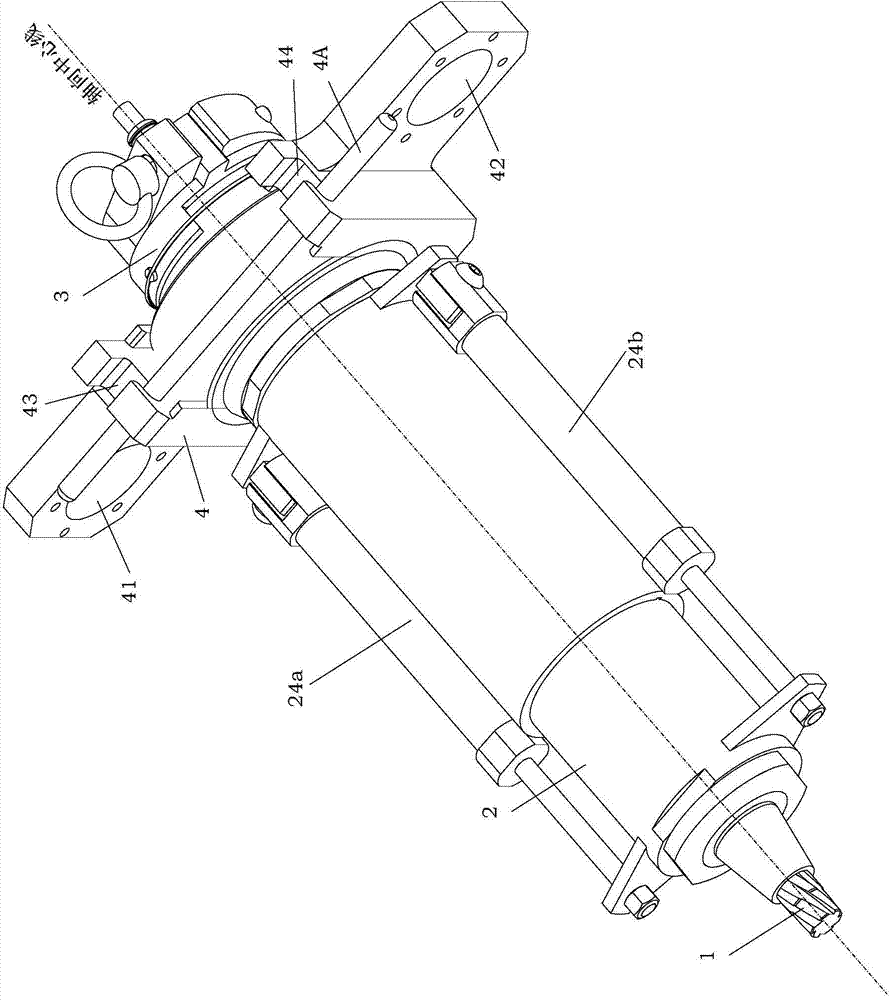

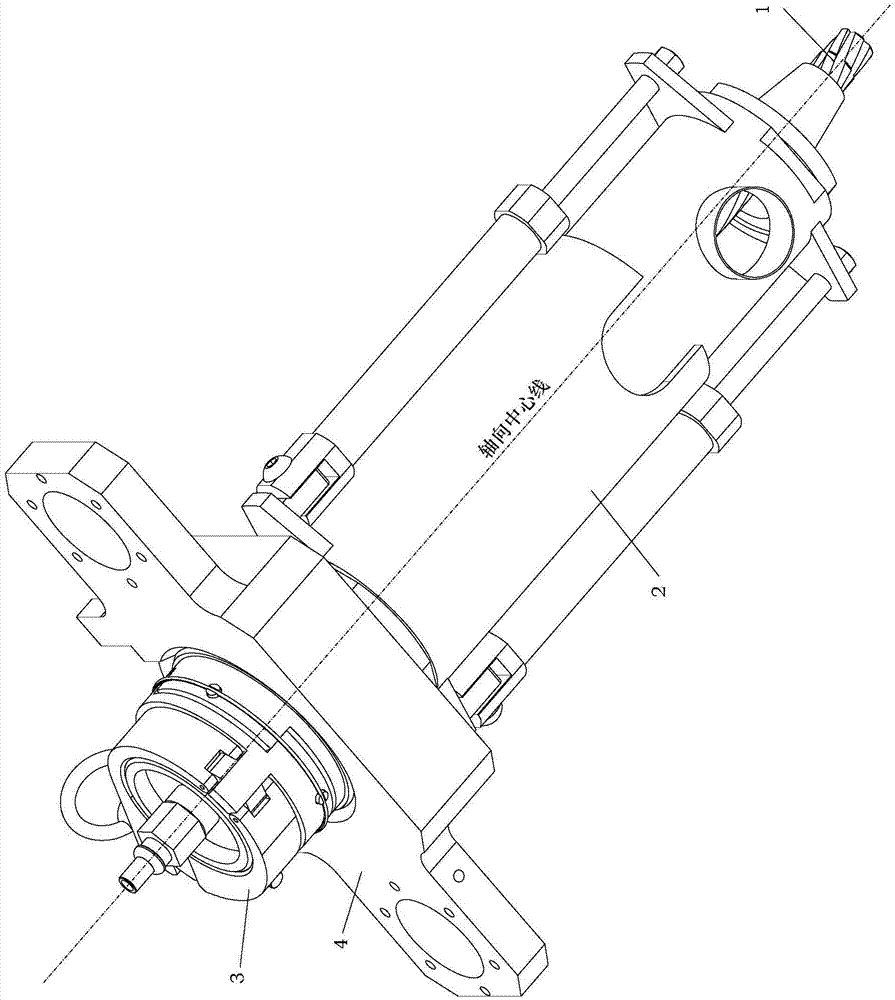

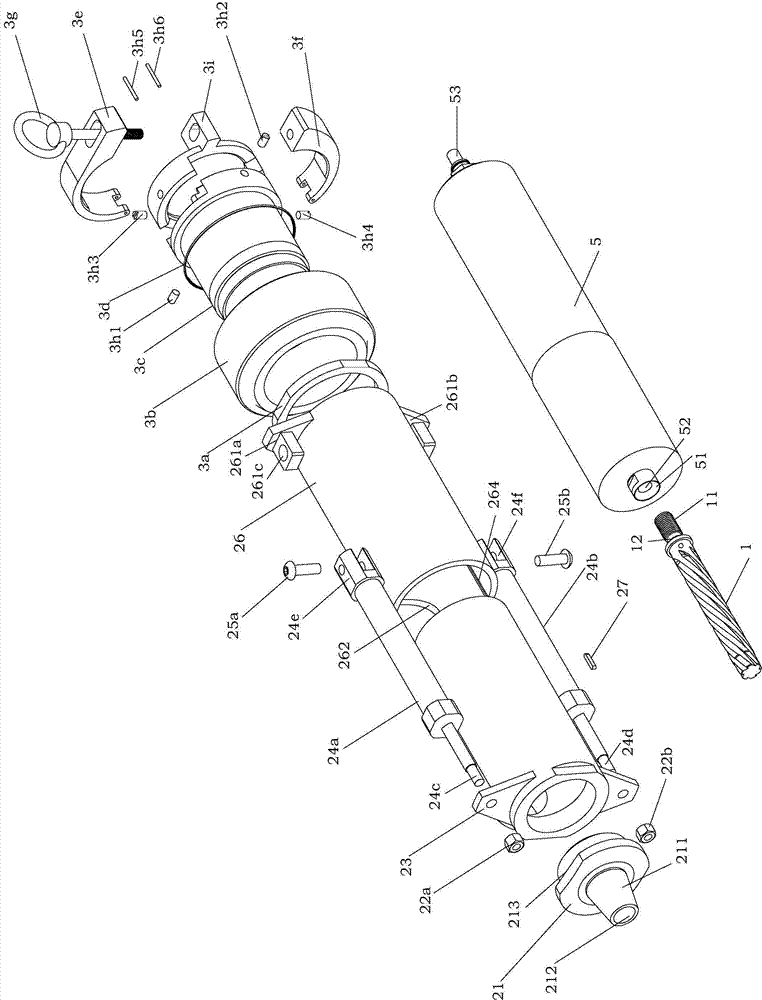

[0046] see figure 1 , Figure 1A , Figure 1B As shown, the present invention designs a quick positioning device applied to an automatic feed drill, and the quick positioning device includes a front section guide assembly 2 , a rear section locking assembly 3 and a lead screw frame 4 .

[0047] In the present invention, the hole making tool on the automatic feed drilling equipment is denoted by reference numeral 1 . The straight handle pneumatic air drill body on the automatic feed drilling equipment is denoted as reference number 5.

[0048] see figure 1 , Figure 1A , Figure 1B As shown, the front end of the hole-making tool 1 is a cutter head; the rear end of the hole-making tool 1 is provided with a rear taper surface 12 and an external thread segment 11 .

[0049] see figure 1 , Figure 1A , Figure 1B As shown, the front end of the straight h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com