3D printed robot that can fly

A 3D printing and aircraft technology, applied in the field of flying robots, can solve the problems of multi-rotor unmanned aerial vehicle robots, etc., and achieve the effect of enhancing 3D printing efficiency, fast printing speed and small size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

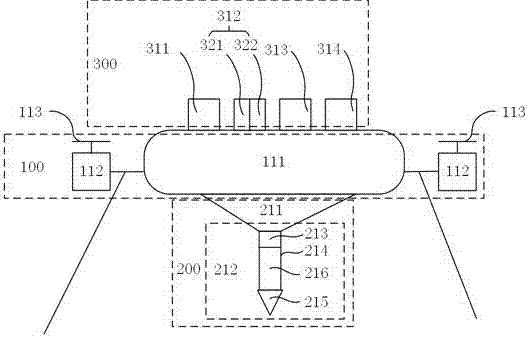

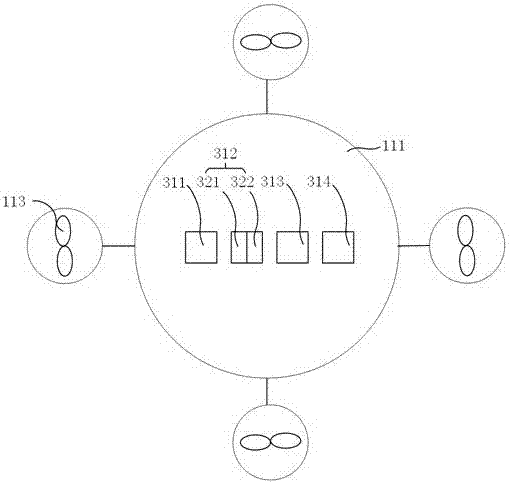

[0029] see figure 1 and figure 2 , a 3D printing robot capable of flying, comprising a multi-rotor unmanned aerial vehicle mechanism 100, a 3D printing mechanism 200, a feedback / communication / control circuit 300, the multi-rotor unmanned aerial vehicle mechanism 100 is fixedly connected to the 3D printing mechanism 200, and the multi-rotor unmanned aerial vehicle mechanism 100 is fixedly connected to the 3D printing mechanism 200. A feedback / communication / control circuit 300 is installed on the human aircraft mechanism 100 at the same time;

[0030] The multi-rotor unmanned aircraft mechanism 100 includes a casing 111, a motion motor 112, and a propeller 113. The motion motor 112 is installed on the casing 111, and the end is connected with the propeller 113.

[0031] The 3D printing mechanism 200 includes a connecting arm 211 and a printing head 212. The connecting arm 211 is fixed on the casing 111 of the multi-rotor unmanned aerial vehicle mechanism 100. The end of the co...

Embodiment 2

[0034] The technical solution of this embodiment is basically the same as that of Embodiment 1, the difference is that:

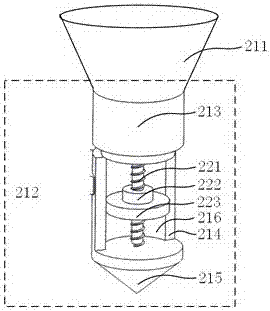

[0035] see image 3, in this embodiment, the 3D printing mechanism 200 should also include a rotating lead screw 221, an extruding nut 222, an extruding piston 223, and the feeding motor 213 is sequentially connected to the rotating lead screw 221, extruding nut 222, extruding piston 223, 3D The printing mechanism 200 is a piston syringe type extrusion feeding mechanism. The printing material 216 is pre-filled into the heating chamber 214, and the rotating screw 221 is driven by the feeding motor 213 to rotate, pushing the extrusion nut 222, and finally pushing the extrusion piston 223 to heat the The printing material 216 is extruded through the extrusion head 215 for 3D printing.

Embodiment 3

[0037] The technical solution of this embodiment is basically the same as that of Embodiment 1, the difference is that:

[0038] see Figure 4 , in this embodiment, the 3D printing mechanism 200 should also include a pulverizing gear 231, the feeding motor 213 is connected to the pulverizing gear 231, the 3D printing mechanism 200 is a motor gear meshing feeding mechanism, the printing material 216 is filamentous when it is not pulverized and heated, and is passed through the feeding The motor 213 drives the crushing gear 231 to rotate, pulverizes and pushes the heated printing material 216 to be extruded through the extrusion head 215 for 3D printing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com