A kind of ultra-micro planar electrode array sensor and its preparation method

A technology of array sensors and microelectrode arrays, which is applied in stress-stimulated microbial growth methods, piezoelectric/electrostrictive/magnetostrictive devices, televisions, etc., and can solve problems such as large electrode size, many recording points, and difficult detection , to achieve the effect of more recording points, uniform performance, and conducive to transient detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

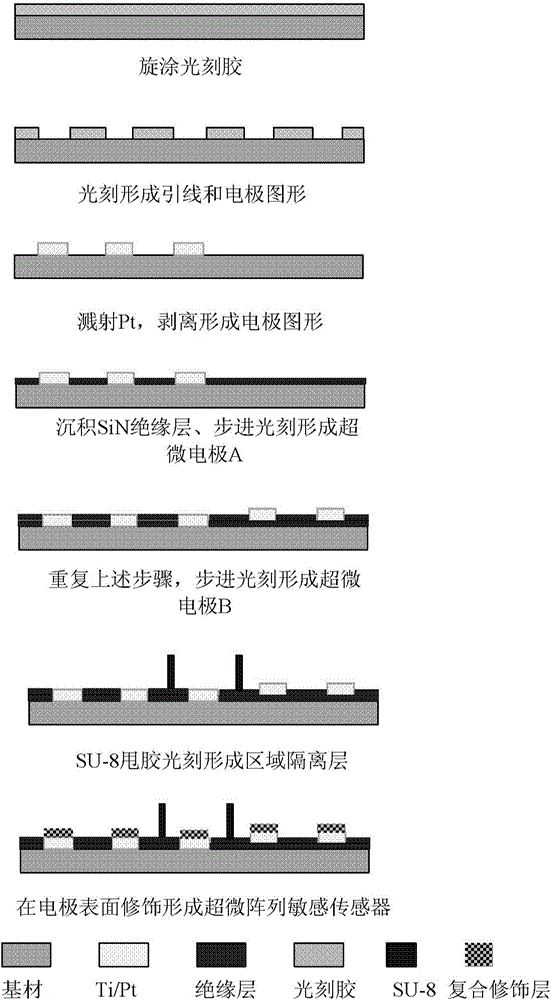

[0035] figure 1 A process flow chart of a preparation method of an ultramicroplanar electrode array sensor proposed by the present invention is shown. Such as figure 1 As shown, the method includes:

[0036] Step 1. After cleaning the insulating substrate, apply photoresist on the substrate; positive or negative resist can be used, and different photoresists can be used according to different plate making methods. After photolithography and development on the glue, the required leads and electrodes are formed to form a micro-electrode array pattern.

[0037] Step 2, sputtering the micro-electrode conductive film layer on the entire substrate, the micro-electrode conductive film layer is a layer of electrode metal layer, peeling off the photoresist to leave the required electrodes, leads and contacts to form the basic metal electrode array. The electrodes are composed of a two-layer structure comprising a lower seed layer of metal titanium (Ti) or chromium (Cr) and an upper...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com