Efficient anaerobic reaction tank for large-scale raising of livestock

An anaerobic reaction tank, livestock technology, applied in anaerobic digestion treatment, chemical instruments and methods, animal husbandry wastewater treatment, etc. problem, to achieve the effect of convenient inversion and mixing, complete separation effect, and strengthening of sufficient mixing and contact.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

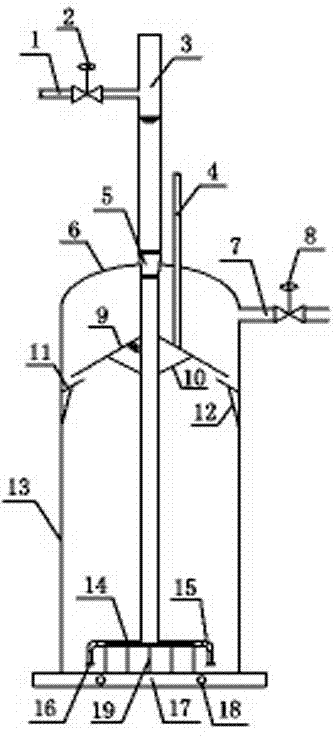

[0020] Below in conjunction with accompanying drawing, the present invention will be further explained and illustrated:

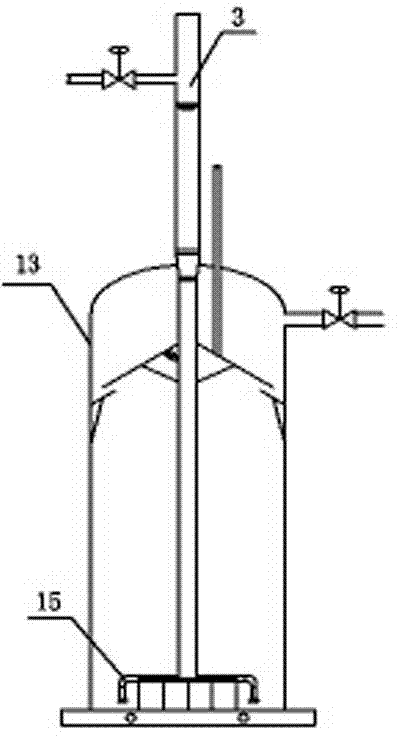

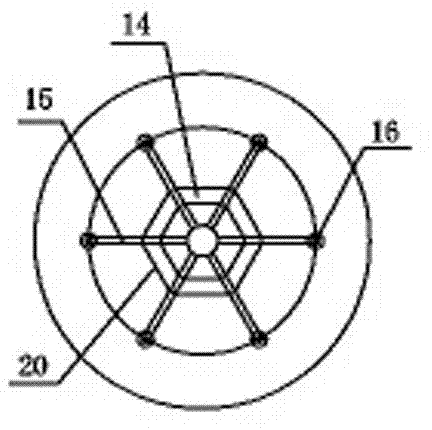

[0021] see figure 1 , a high-efficiency anaerobic reaction tank for large-scale breeding of poultry and livestock, comprising an anaerobic reaction tank body 13, a central pipeline 3 is arranged at the central position of the anaerobic reaction tank body 13, and the height of the central pipeline 3 is the height of the anaerobic reaction tank 5 / 3 of the height of the body 13, the central pipeline 3 runs through the anaerobic reaction tank body 13, and the bottom of the central pipeline 3 is fixed with a water distribution pipeline 15 through a fixed bracket 14, and the water distribution pipeline 15 is composed of 6 water distribution branch pipelines. The 6 water distribution branch pipes are evenly distributed with the bottom of the central pipe 3 as the center of the circle, the angle between each adjacent two water distribution branch pipes is 60 degree...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com