SMA-piezoelectric frictional combined damper

A composite damping and damper technology, which is applied to building components, earthquake resistance, etc., can solve the problems of not being able to meet the energy dissipation requirements of earthquakes of different intensities, the energy dissipation effect is not significant, and there is no self-resetting ability. A large number of connectors and construction inconvenience, the effect of eliminating stress relaxation of bolts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Below in conjunction with accompanying drawing and specific embodiment describe the present invention in detail:

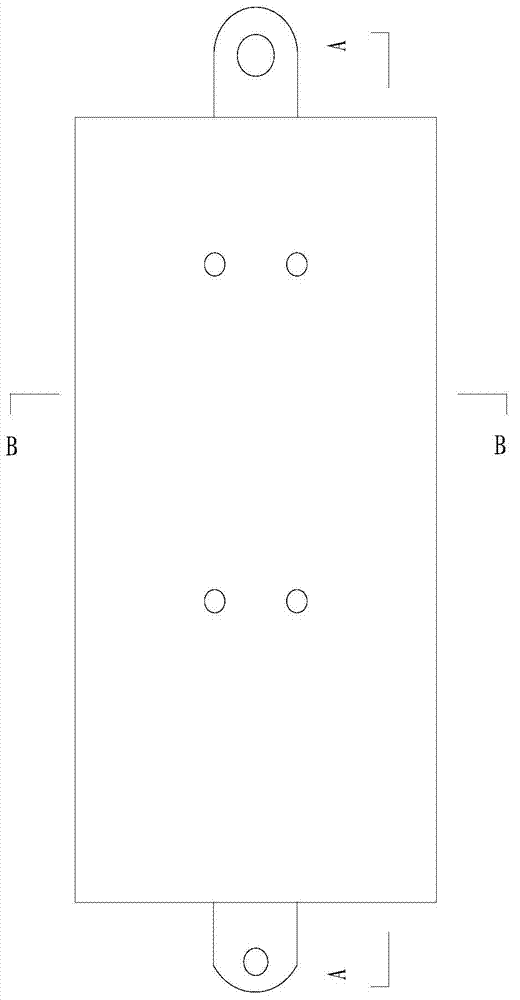

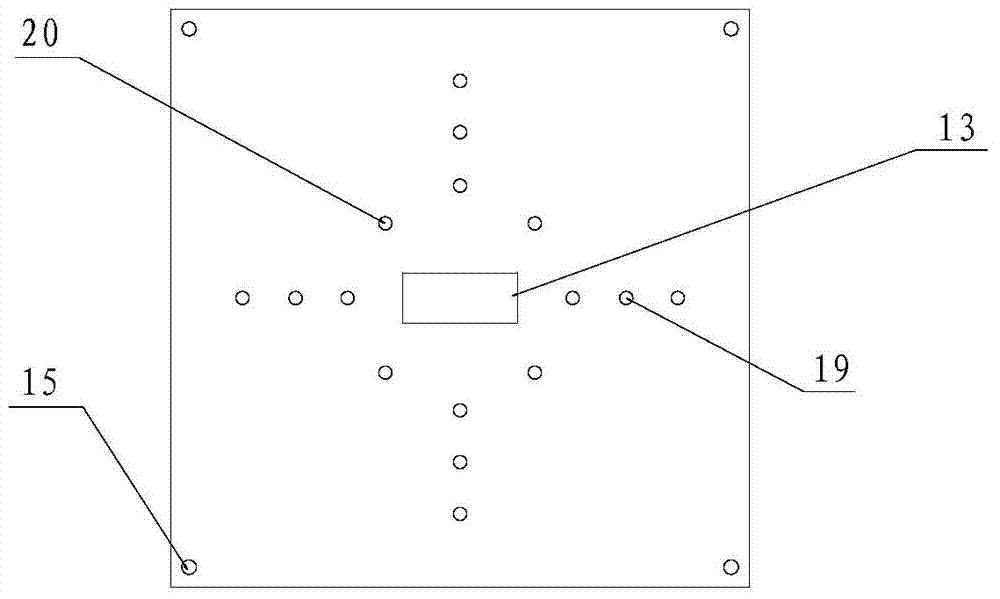

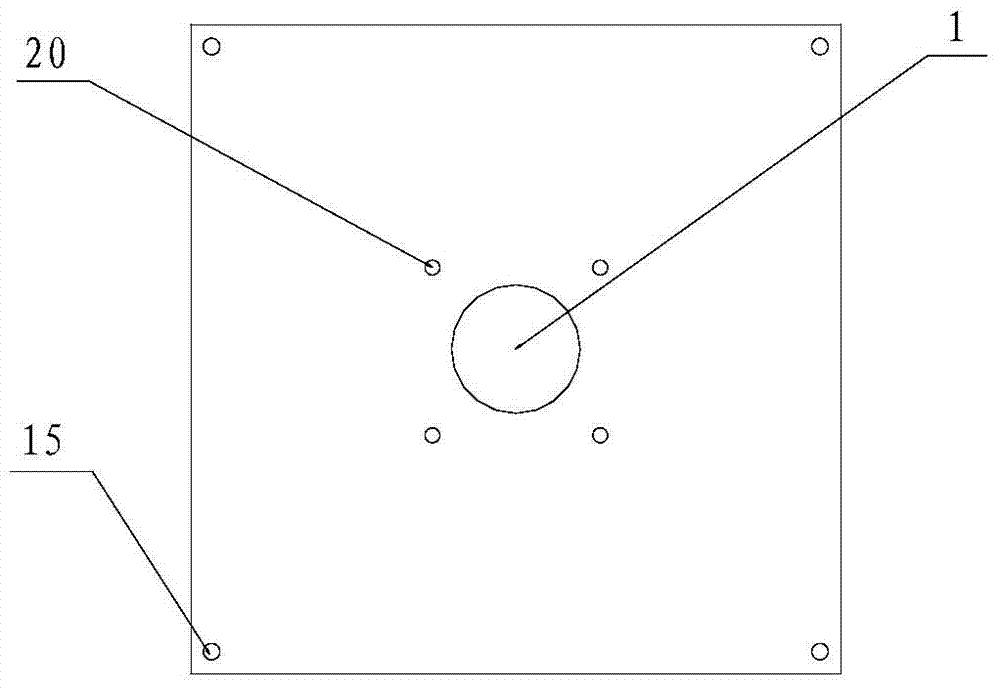

[0034] An SMA-piezoelectric friction composite damper, such as figure 1 As shown in -4, it includes sliding shaft 1, damper housing 2, piezoelectric ceramic protective cover and force sensor 4, piezoelectric ceramic driver 5, connecting steel 7, sliding plate 8, friction plate 9, and cross-shaped connecting plate 11. Solid steel column 14, spring 17, force sensor 18, shape memory alloy wire 21, clamping block 22;

[0035] like Figure 4 As shown in -6, the cross-shaped connecting plate 11 is installed in the middle part of the damper housing 2 by welding, and four sets of friction plates 9 are arranged between the upper top plate of the damper housing 2 and the cross-shaped connecting plate 11, each The set of friction plates 9 are parallel to the side wall of the damper housing 2 and installed between the upper top plate of the damper housing 2 and the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com