A steel grid support structure on the roof of a cement warehouse

A technology for supporting structures and cement siloes, which is applied to pillars, roofs, building components, etc., can solve the problems of ineffective and seamless connection between steel roof trusses and concrete silos, high requirements for lifting and hoisting construction operations, and long occupation of construction sites. , to achieve the effect of construction quality and personal safety of workers, saving the cost of temporary support materials, and short construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

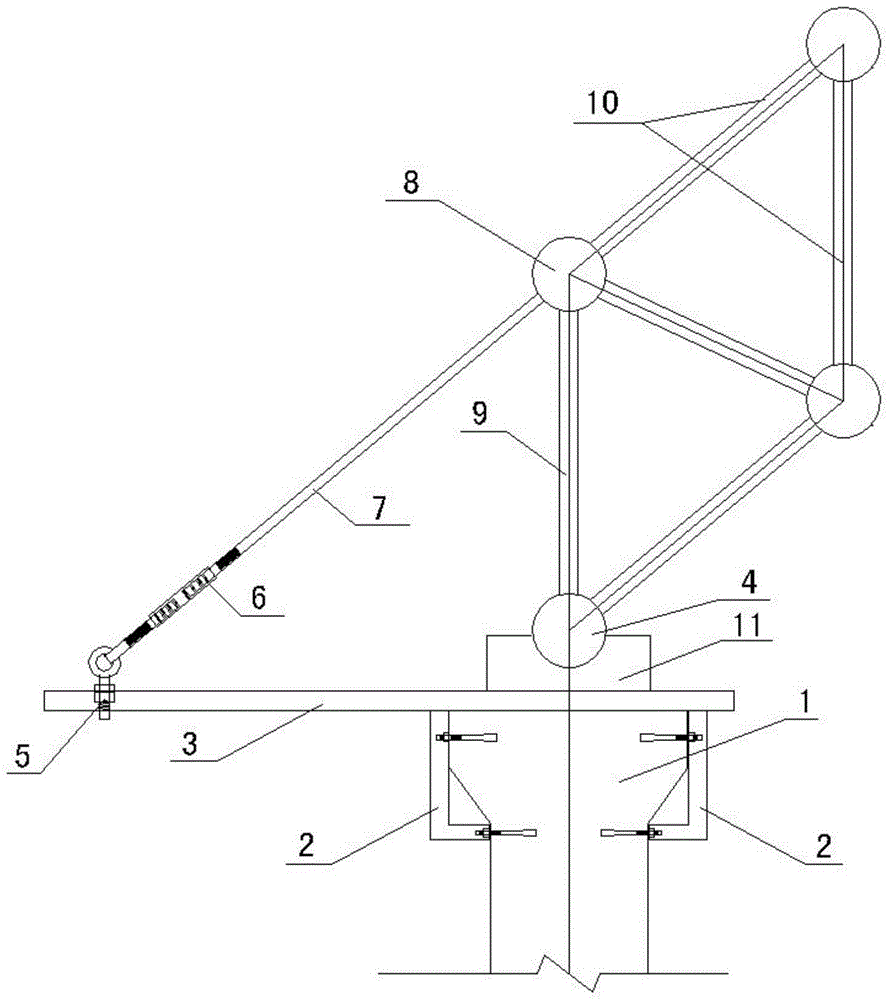

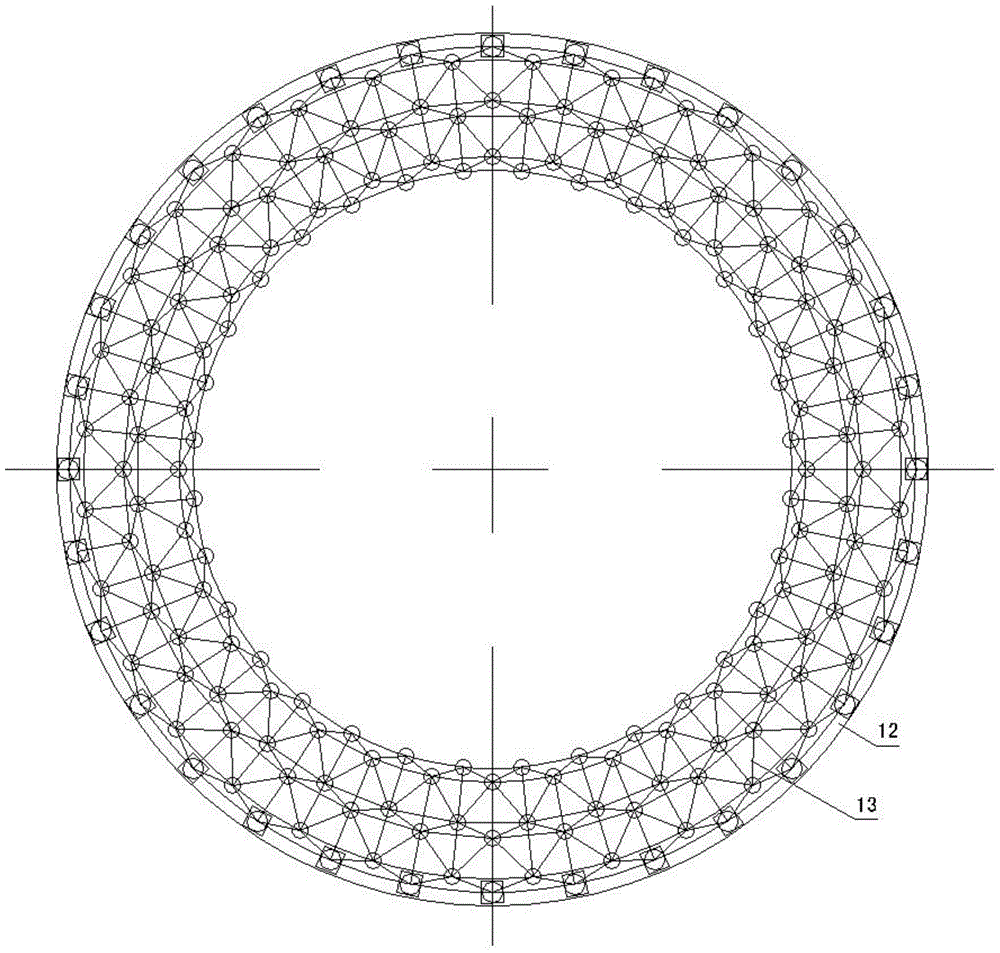

[0021] see figure 1 , in the present embodiment, the supporting structure of the steel grid frame on the top of the cement silo is: on the circular top ring beam 12 of the cement silo wall 1, the basic ring 10 of the grid frame is fixedly set by the support frame, and the structural form of the support frame is: On the circular top ring beam 12 of the cement storehouse wall 1, the shaped steel legs 2 are arranged symmetrically on the inner wall and the outer wall of the cement storehouse wall 1 respectively, and on the circular top ring beam, use The shaped steel cantilever beam 3 is fixedly installed in the form of a cantilever on the shaped steel leg 2, and the shaped steel cantilever beam 3 is horizontally overhanging towards the outside of the clinker storehouse wall 1; The seat 11 is fixedly provided with each support bolt ball 4, and the upright column 9 is fixedly installed on the support bolt ball 4, and the first layer of upper chord spiral ball 8 is fixedly installed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com