A kind of direct injection molding leather-like texture automotive interior material and preparation method thereof

An injection molding, automotive interior technology, applied in the field of materials, can solve the problems of assembly size, pollution of the air in the car, migration of harmful substances, etc., to achieve the effect of reducing material and manufacturing costs, reducing material consumption, and reducing manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

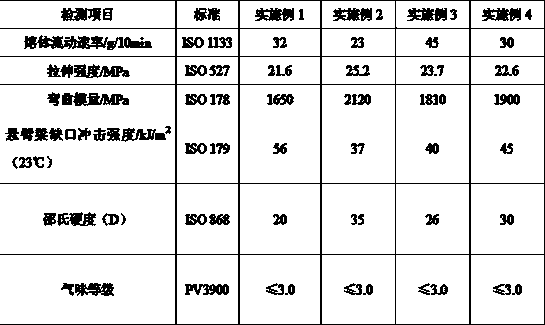

Embodiment 1

[0045]Add Cytec 3808, antioxidant 1010, calcium stearate, and polypropylene into the twin-screw extruder according to the weight ratio of 15:15:10:60 to prepare functional additive masterbatch; 35 parts of polypropylene, 25 parts of polybutylene terephthalate elastomer, 5 parts of chlorinated polyethylene with 33% chlorine content, 5 parts of maleic anhydride grafted polypropylene, polyether polyol and diisocyanate copolymer 15 parts of compound, 10 parts of talcum powder, 5 parts of functional additive masterbatch, 0.5 part of odor eliminating agent, described odor eliminating agent is the porous polyethylene that contains water and essence and component is 5:5, puts into high-speed mixer Mix for 1 min to obtain the mixture; add the obtained mixture through the main feeding hopper of the twin-screw extruder, close the exhaust port of the machine mouth, plasticize, extrude, draw, air-dry, and granulate to obtain a soft A polypropylene composite material with textured character...

Embodiment 2

[0047] Add Cytec 3808, antioxidant 168, silicone, and polypropylene into the twin-screw extruder according to the weight ratio of 15:15:10:60 to prepare functional additive masterbatch; 70 parts of propylene, 10 parts of thermoplastic polybutylene terephthalate elastomer, 3 parts of chlorinated polyethylene with 20% chlorine content, 2 parts of maleic anhydride grafted polyethylene, polycarbonate diol and 5 parts of diisocyanate copolymer, 20 parts of whiskers, 2 parts of functional additive masterbatch, 3 parts of odor eliminating agent, described odor eliminating agent is the ethylene-vinyl acetate copolymer that will contain water and alcohol ratio is 5:5 , put into a high-speed mixer and mix for 3 minutes to obtain a mixture; the obtained mixture is added through the main feeding hopper of a twin-screw extruder, and plasticized, extruded, drawn, air-dried, and granulated to obtain a soft Then, put the softened polypropylene composite material into the injection molding mac...

Embodiment 3

[0049] Cytec 3808, antioxidant 1010, polyethylene wax, and polypropylene copolymer are added to the twin-screw extruder according to the weight ratio of 15:15:10:60, and activated carbon is added through side feeding to prepare a functional additive master Granules; 50 parts of copolymerized polypropylene with a melt index of 50g / 10min, 20 parts of polybutylene terephthalate and polyether copolymer, 8 parts of chlorinated polyethylene with a chlorine content of 40%, grafted with maleic anhydride 3 parts of polypropylene, 10 parts of polyether polyol and diisocyanate copolymer, 15 parts of calcium carbonate, 3 parts of functional auxiliary agent masterbatch, 2 parts of odor eliminating agent, described odor eliminating agent will contain essence and ether for 5 parts The porous polyacrylamide of 5:5 is put into a high-speed mixer and mixed for 2min to obtain a mixture; the obtained mixture is added through the main feeding hopper of a twin-screw extruder, and the exhaust port of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com