High-precision oil three-phase automatic metering device and metering method thereof

An automatic metering and high-precision technology, applied in the directions of measurement, earth-moving drilling, and fluid extraction, etc., can solve the problems of large damping coefficient, complex process flow, large error in measurement results, etc., achieving a high degree of automation, good separation effect, and precision. Monitoring the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

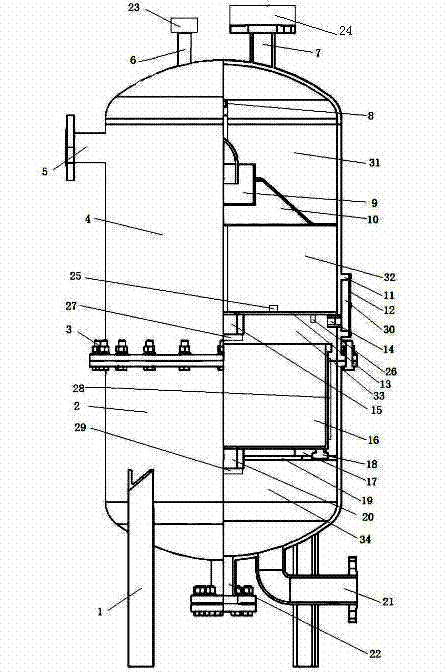

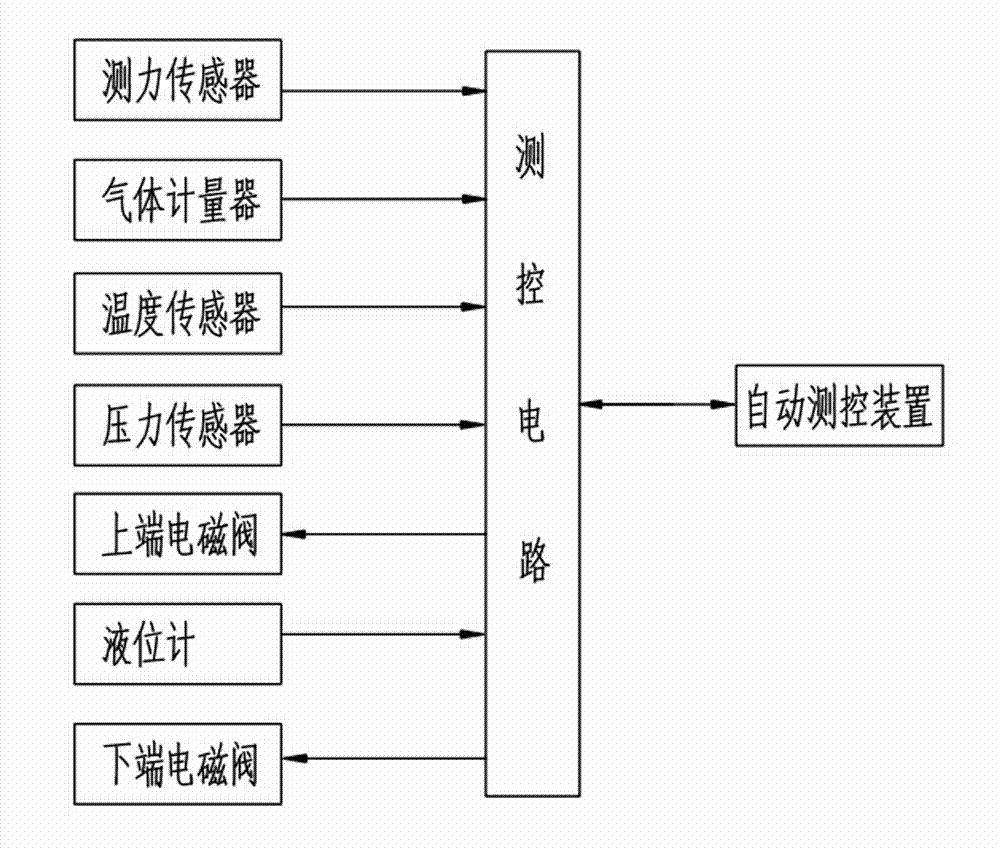

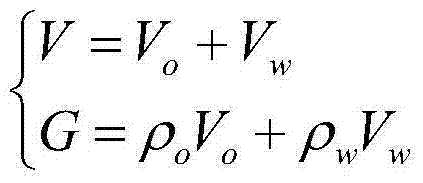

[0023] See attached figure 1 and figure 2 , a kind of high-precision petroleum three-phase automatic metering device, comprises a tank body, and described tank body comprises upper tank body 4 and lower tank body 2, and described upper tank body 4 and lower tank body 2 are connected by fastener 3, The side walls of the upper tank body 4 are respectively provided with an inlet pipe 5 and an electronic warehouse 11, the electronic warehouse 11 is provided with an electronic warehouse cover 12 outside, and a measurement and control circuit 30 is arranged inside, and the upper part of the upper tank body 4 is respectively provided with a connection End 6 and exhaust pipe 7, wherein said connection end 6 is connected with air pressure balance valve 23, guarantees that the air pressure in the tank is in a safe state, and said exhaust pipe 7 is connected with gas meter 24, and said gas meter 24 is separated After the gas volume is measured, it is connected to the gas pipeline and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com