Crystallizing material discharging valve

A discharge valve and valve technology, applied in the chemical industry, can solve the problems of container beating deformation, affecting the discharge effect, shortening the service life of equipment, etc., and achieve the effect of simple and convenient installation and convenient production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with drawings and embodiments.

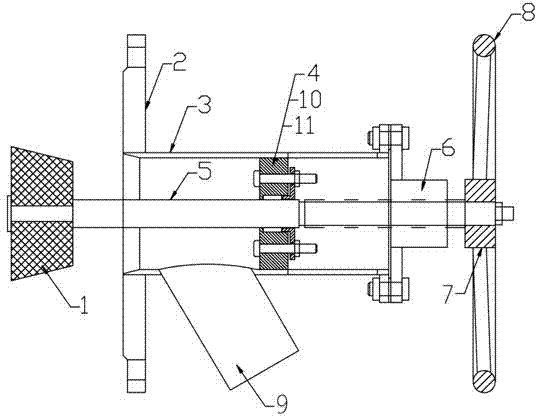

[0013] Such as figure 1 As shown, a crystallization material discharge valve is a discharge valve in the discharge process of industrial crystallization materials. The discharge valve is divided into four parts, consisting of a spiral handwheel 7, a screw rod 5, a sealing device 4, a rubber valve plug 1, and a human-shaped discharge pipe 9. The spiral handwheel 7 is a disc handle 8 fixed on the screw rod 5. Above, a sealing device 4 is installed on the screw rod 5. The sealing device 4 is internally threaded and screwed on the screw rod 5. The sealing device 4 is a packing gland 10 fixed on the stuffing box 11. The sealing device 4 is tightly sleeved on the valve cylinder. body 3, one end of the valve cylinder 3, the valve stem seat 6 fixes the screw rod 5 on the valve cylinder 3, the other end of the valve cylinder 3, the valve seat 2 is fixed on the valve cylinder 3,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com