Reverse combustion type biological straw compressed block heating and cooking dual-purpose furnace

A bio-straw and anti-burning technology, which is applied in the direction of household stoves/stoves, applications, heating methods, etc., can solve problems such as single function, simple structure, pollution, etc., to achieve optimized internal structure, rapid and thorough ash removal, and high combustion efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

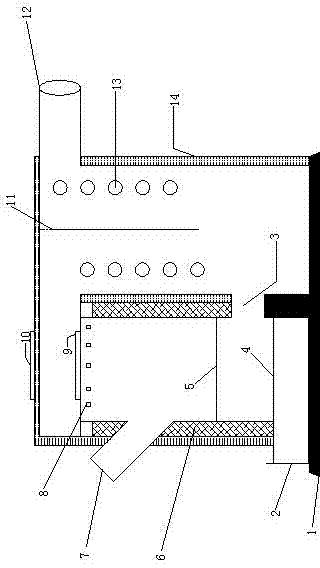

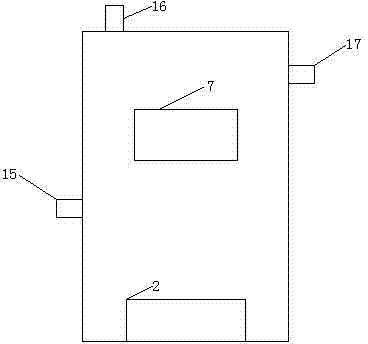

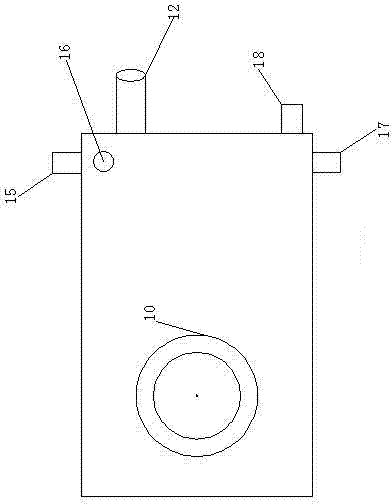

[0021] Embodiment 1: This embodiment discloses a double-grate back-firing biomass heating furnace, the structure of which is shown in Figure 1-Figure 3 , the furnace body is supported on the base 1, which is a double-grate reverse combustion biomass heating furnace. Its furnace body and all other components are made of heat-resistant stainless steel, heat-resistant cast steel and other metal materials. The top of the furnace body is provided with a water inlet 16, and the outer furnace cover 10 is used to buckle the cover. One side is provided with a water outlet 17 , and the other side is provided with a water return port 15 . Two rows of hot water suction pipes 13 are arranged, and the two rows of hot water suction pipes 13 are arranged in a staggered manner in the flue. The outer wall of the iron sheet and the water jacket 14 constitute a furnace wall, and a refractory layer 6 is arranged between the inner wall of the furnace and the water jacket 14 .

[0022] The furnac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com