Visual detection method of pulverized coal combustion ratio

A technology of pulverized coal combustion rate and detection method, which is applied in the direction of using combustion for chemical analysis, etc., can solve the problem of low coal combustion rate and achieve accurate results of combustion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

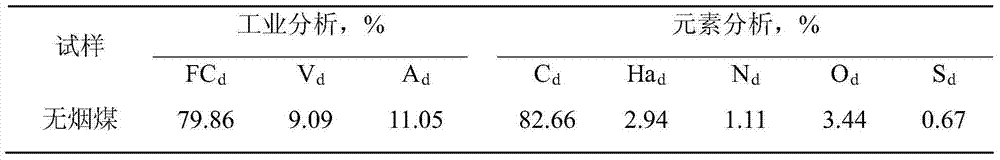

[0024] A kind of anthracite was selected as the test sample, and its industrial analysis and elemental analysis results are shown in Table 1, respectively.

[0025] Table 1 Industrial analysis of anthracite samples, wt%

[0026]

[0027] The steps of a visual detection method for pulverized coal combustion rate are as follows:

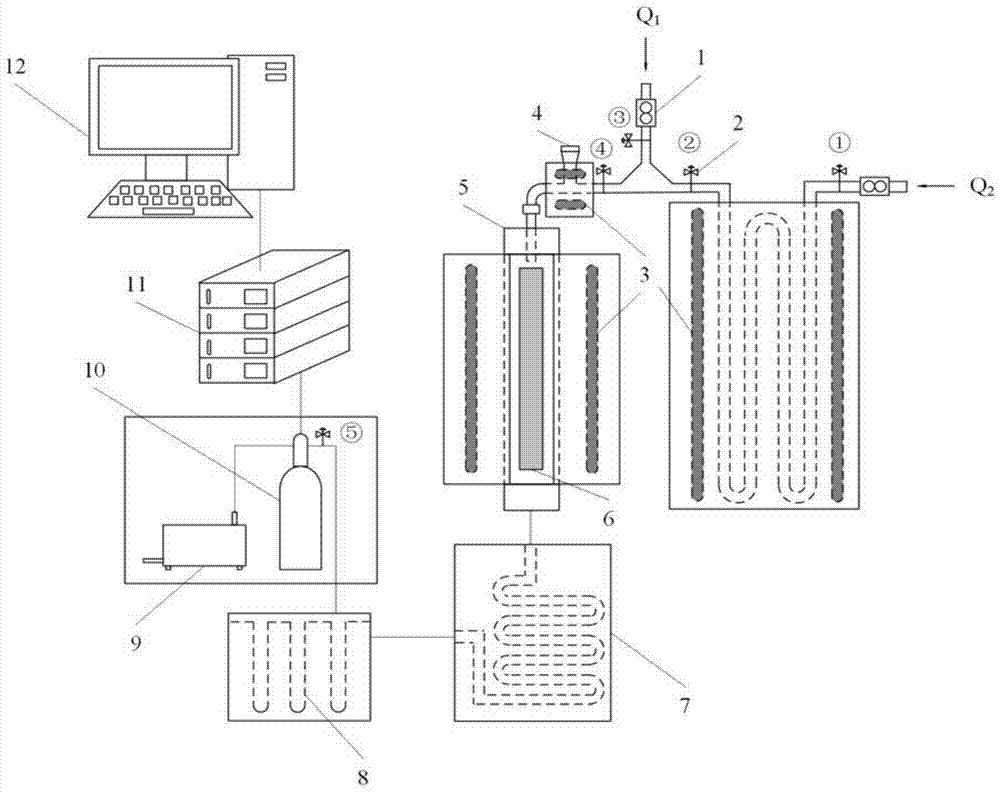

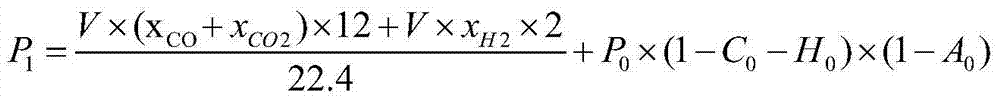

[0028] (1) Place the lumpy coal sample in a constant temperature drying oven at 105°C to dry for 4 hours, then use a sealed vibrating pulverizer to crush the coal sample, crush and sieve the coal sample to below 200 mesh (0.074mm), as the Test samples. Open all the electromagnetic valves 2 (①, ②, ③, ④, ⑤) of the device, use the air in the carrier gas preheating furnace 3 as the carrier gas for injecting pulverized coal, and close the electromagnetic valves at both ends of the pulverized coal carrier gas preheating furnace. Valves ① and ② preheat the pulverized coal carrier gas through the heating furnace, and preheat the pulverized coal carrier ga...

Embodiment 2

[0052] A kind of bituminous coal was selected as the test sample, and its industrial analysis and elemental analysis results are shown in Table 3, respectively.

[0053] Table 3 Industrial Analysis and Elemental Analysis of Bituminous Coal Samples

[0054]

[0055] The steps of a visual detection method for pulverized coal combustion rate are as follows:

[0056] (1) Crush the lumpy coal sample through a sealed vibrating pulverizer, and select coal powder below 200 mesh (0.074mm) as the test sample. First, open the electromagnetic valve 2 (①, ②, ③, ④, ⑤) of the device, and feed air into the preheating furnace 3 as the carrier gas for injecting pulverized coal for preheating. When the pulverized coal carrier gas preheating furnace is full of gas Finally, close the electromagnetic valves ① and ② at both ends of the pulverized coal carrier gas preheating furnace, and enter the pulverized coal to be burned into the pulverized coal preheating device 4 through the pulverized coa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com