Motor control method, motor module and cooling device using same

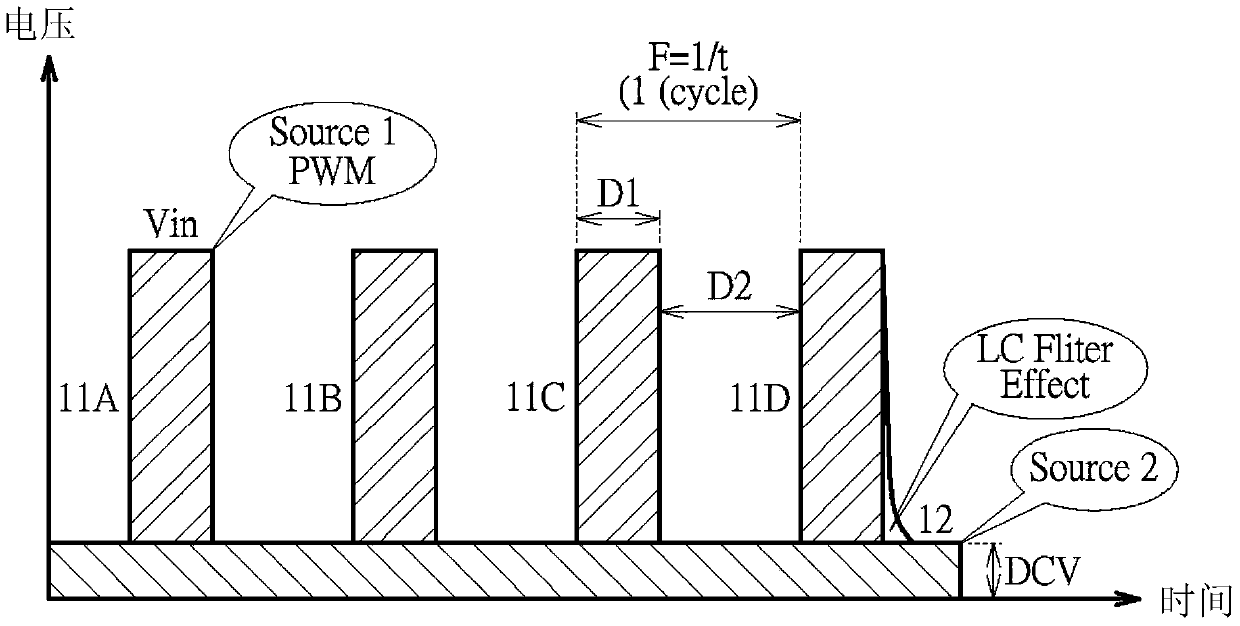

A technology of motor control and motor controller, applied in the direction of excitation or armature current control, etc., can solve the problems of excessive running noise, inability to rotate at low speed, etc., and achieve the effect of reducing startup noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] In order to have a further understanding of the purpose, structure, features, and functions of the present invention, the following detailed descriptions are provided in conjunction with the embodiments.

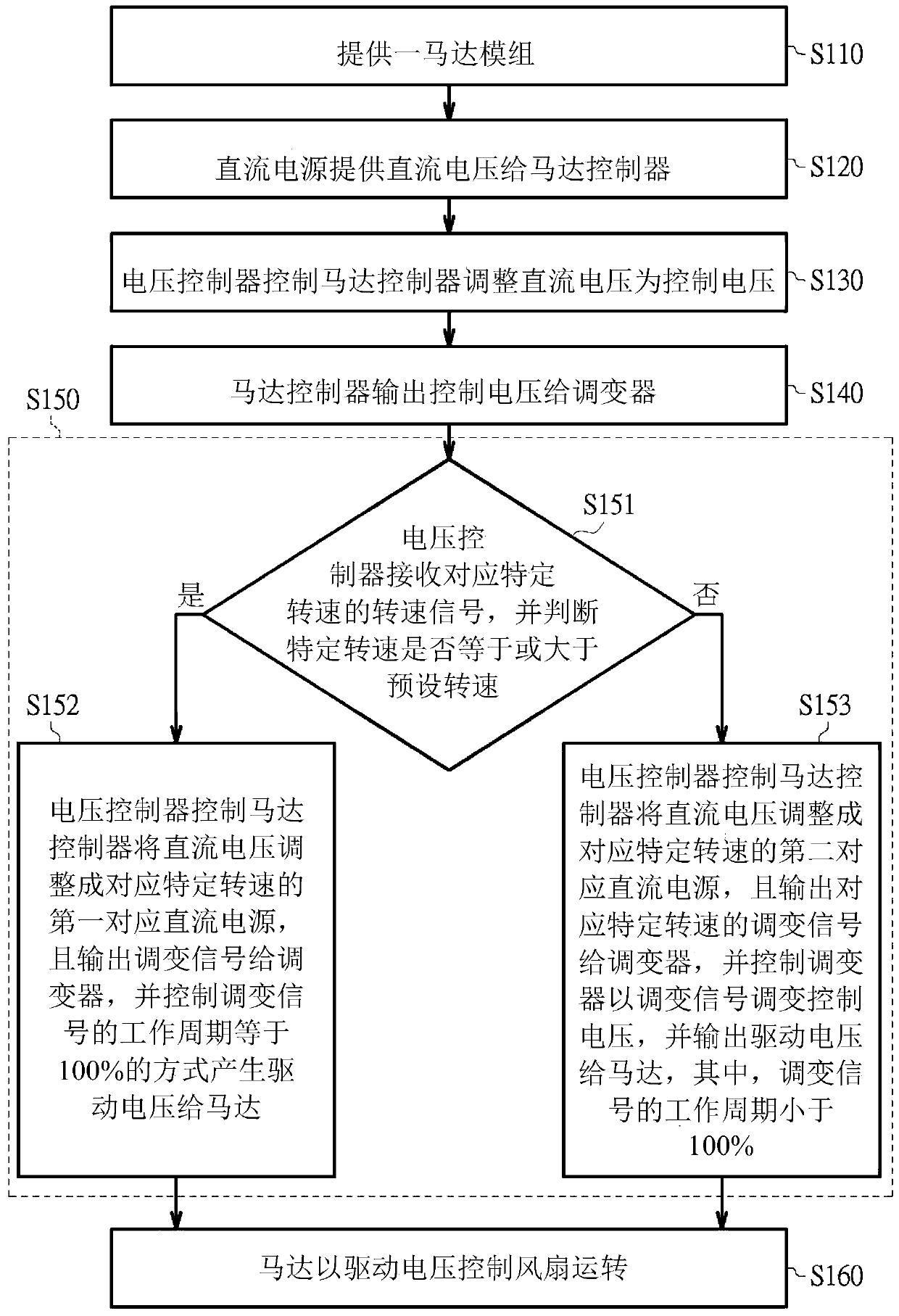

[0048] figure 2 A flow chart of a motor control method according to an embodiment of the invention is shown.

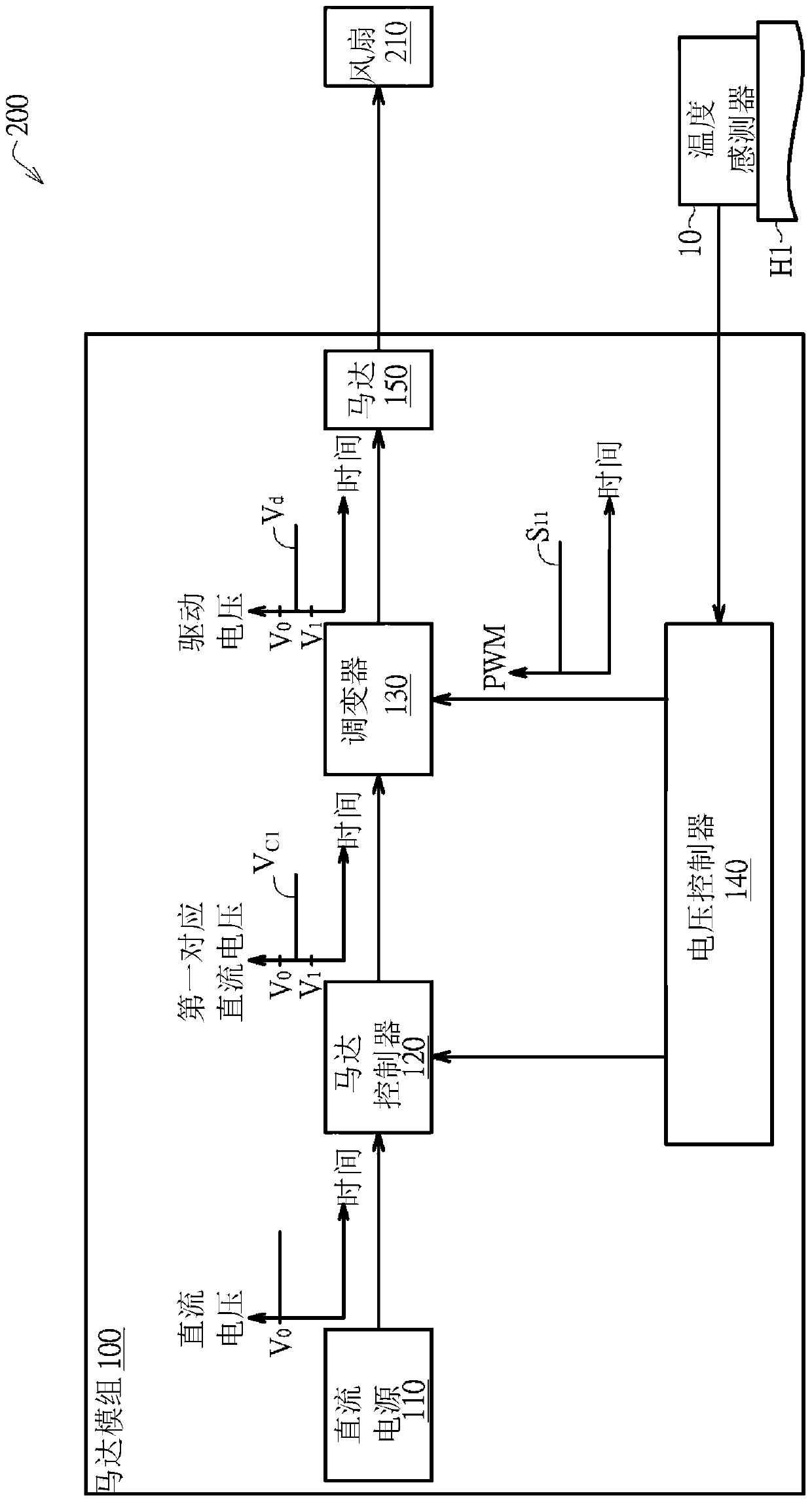

[0049] In step S110, provide as image 3 The motor module shown. image 3 A functional block diagram of a heat dissipation device according to an embodiment of the present invention is shown. The heat dissipation device 200 includes a motor module 100 and a fan 210 . The motor module 100 includes a DC power supply 110 , a motor controller 120 , a modulator 130 , a voltage controller 140 and a motor 150 . The motor module 100 is used to control the operation of the fan 210 to reduce the temperature of the hot spot H1. The motor 150 is, for example, a DC motor.

[0050] In step S120, the DC power supply 110 provides a DC voltage V 0 to the motor control...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com