Centering device for plate-shaped work piece

A technology of plate-shaped workpieces and centering devices, applied in positioning devices, feeding devices, measuring devices, etc., can solve problems such as difficulty in conveying two pieces, reduced operation rate of forming presses, difficulty in speeding up, etc., to shorten calculation time , reduce supply costs, and improve versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

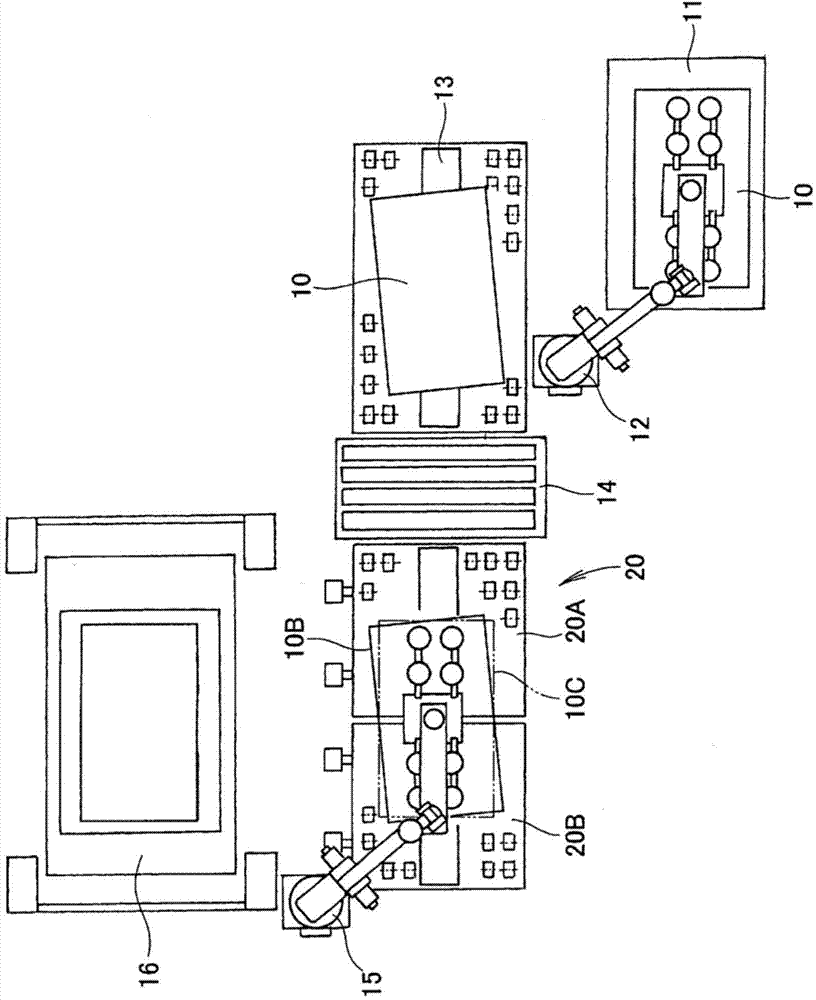

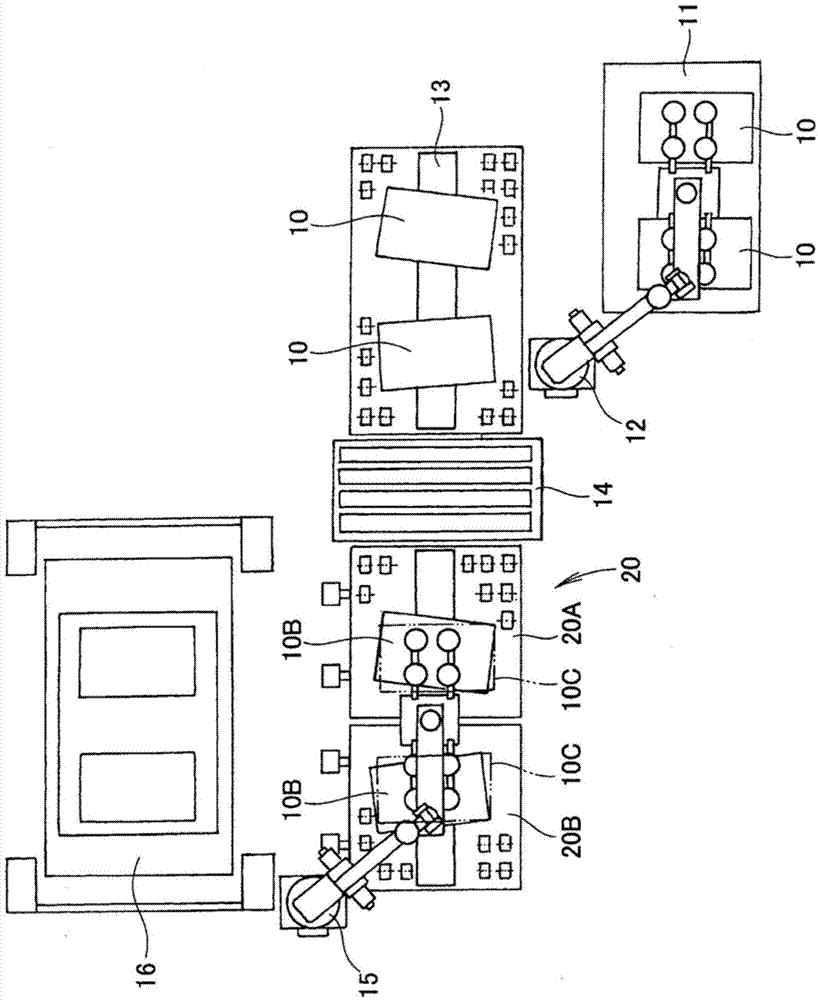

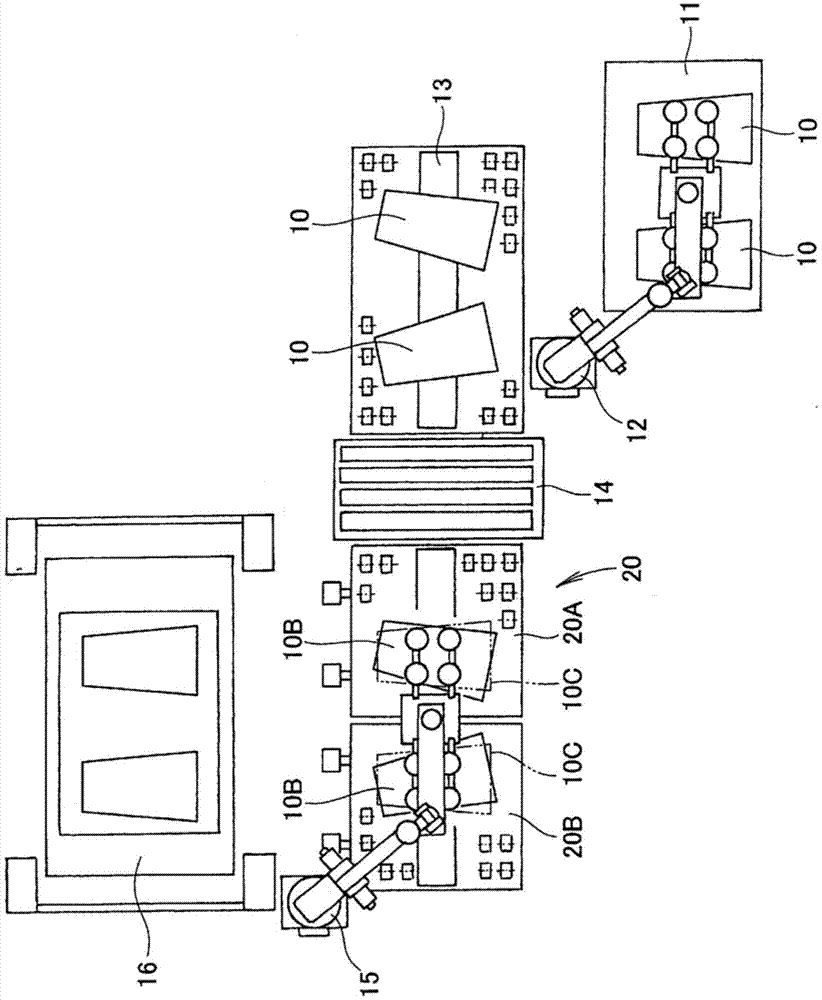

[0046] Such as figure 1 As shown, one sheet of plate-shaped workpiece 10 fed from the previous process is placed on the receiving table 11. The first robot 12 moves the plate-shaped workpiece 10 from the receiving table 11 to the entrance table 13. The plate-shaped workpiece 10 is put into the washing machine 14 from the entrance table 13 in a timely manner, and is washed. Then, the cleaned plate-shaped workpiece 10 is conveyed to the first centering device 20A and the second centering device 20B.

[0047] In this case, the plate-shaped workpiece 10 may be a vertically long material that straddles the first centering device 20A and the second centering device 20B.

[0048] Then, after cleaning, the plate-shaped workpiece before centering is denoted with reference numeral 10B, and the plate-shaped workpiece after centering is denoted with reference numeral 10C, thereby identifying the plate-shaped workpiece 10.

[0049] In addition, the first centering device 20A and the second cent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com