Ship bulkhead

A technology for ships and next walls, applied in the direction of hull bulkheads, hulls, hull parts, etc., can solve the problems of not considering the action distribution, inability to effectively reduce the buckling yield strength of the next wall, and reduce the weight of the next wall, so as to prevent the buckling and yielding of the next wall. Strength-enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

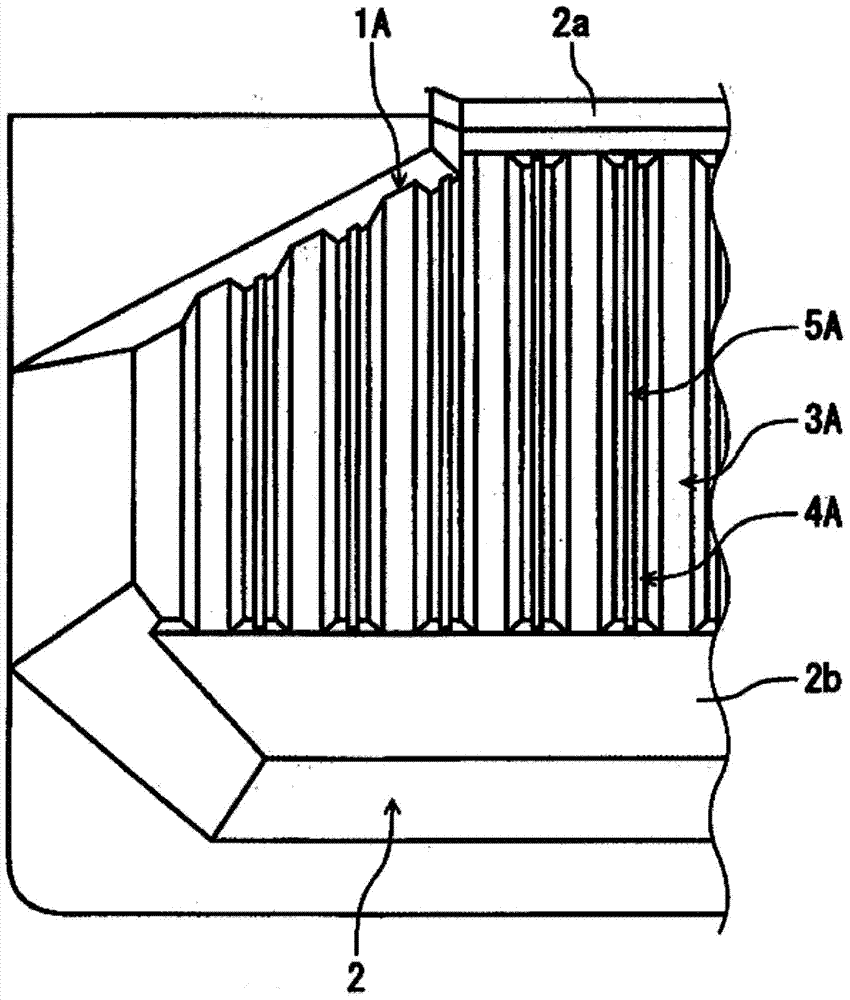

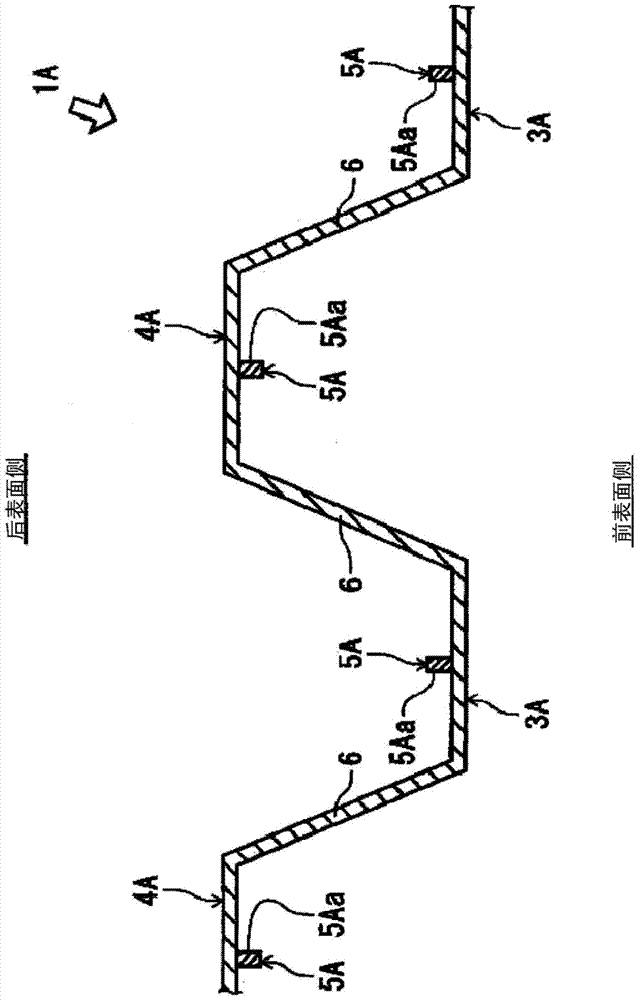

[0062] Figure 1 to Figure 3 It is a figure which shows the 1st Embodiment of the ship partition of this invention, The ship partition 1A of this 1st Embodiment is a so-called transverse partition partitioning the cabin of a ship in the direction perpendicular to the direction of travel of a ship, and as figure 1 As shown, in a cabin 2 having an opening 2a for loading in and out of the upper part, the bulkhead 1A for a ship is placed and fixed on a bulkhead platform (seat) 2b.

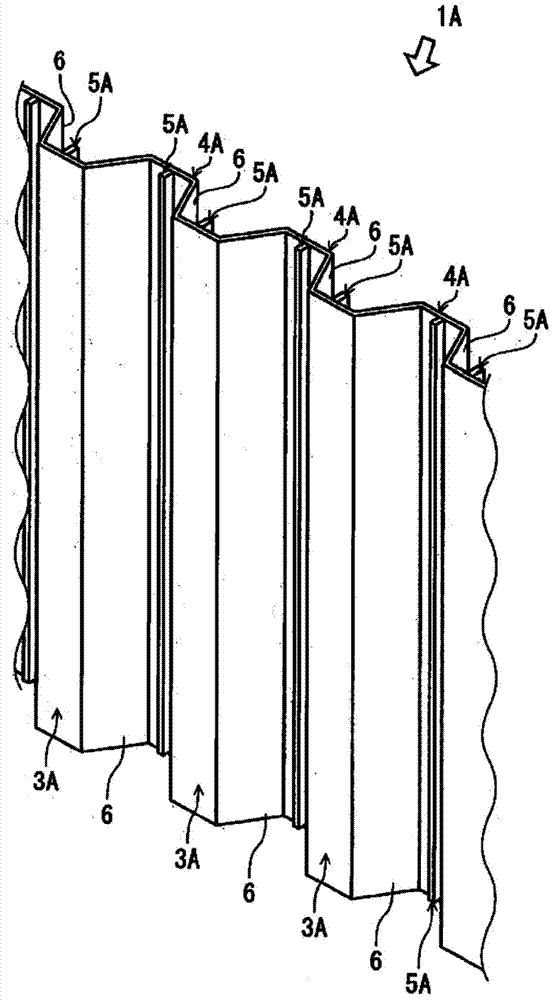

[0063] The partition wall 1A is formed of a thick metal plate, and has a corrugated structure in which a plurality of flat plate-shaped surface member portions 3A, 4A extending in the vertical direction protrude alternately to the front surface side and the rear surface side of the wall surface of the partition wall. The cabin 2 is extended over the entire width of the width direction (left-right direction). Furthermore, each of the above-mentioned surface member portions 3A, 4A is provided with a ri...

no. 2 Embodiment approach

[0082] In the above-mentioned first embodiment, the case where the rib 5A is provided over the entire length (from the lower end to the upper end) of the surface member portions 3A, 4A in the longitudinal direction has been illustrated and described. However, the present inventors considered that there is room for further improvement regarding the range in which the rib 5A is provided, and intensively studied the range in which the rib 5A is provided.

[0083]Then, the inventors of the present invention conducted a more detailed analysis of the distribution of the bending moment generated in the height direction of the surface member portion of the partition wall when, for example, the cabin is filled with seawater, and obtained the following knowledge: 3A, 4A) and the bending moment generated in the surface member portions 3A, 4A), the range in which the rib 5A is provided is appropriate, and the weight reduction of the partition wall 1A and the improvement of the buckling yie...

no. 3 Embodiment approach

[0110] In the above-described first embodiment, the shape of the plate surface of the rib 5A is shown to be, for example, a substantially rectangular shape, but the shape of the plate surface of the rib 5A of the present invention is not limited to this shape. Therefore, the present inventors considered that the bending moments generated in the surface member portions 3A and 4A were not uniformly distributed when the cabin was filled with seawater (see Figure 5 , 6 ), so the shape of the plate surface of the rib 5A is not substantially rectangular is the most suitable, so refer to Image 6 The present embodiment was completed by intensively examining the appropriate shape of the plate surface of the rib 5A.

[0111] like Image 6 As shown, the bending moments generated in the surface member portions 3A and 4A are not uniformly distributed in the longitudinal direction (height direction). Specifically, the bending moments generated in the buckling-risk portion A and the buc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com