Silicon nitride sintered body and sliding member using same

A technology of sliding components and sintered bodies, which is applied in the direction of anti-centrifugal force rotating parts, bearing elements, mechanical equipment, etc., can solve problems such as insufficient wear resistance, inability to stabilize high-speed rotating drive, and increased deviation of bearing life, etc., to achieve reduction The effect of threshing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

[0030] The first embodiment relates to a silicon nitride sintered body, which is characterized in that: when XRD analysis is performed on the silicon nitride sintered body, when 29.6±0.3° and 31.0±0.3° corresponding to the hexagonal α-SiAlON crystal The strongest peak intensity detected at ° is set as I 29.6° , I 31.0° , on the other hand will be corresponding to β-Si 3 N 4 The strongest peak intensity detected at 33.6±0.3° and 36.1±0.3° of the crystal is set as I 33.6° , I 36.1° When , each strongest peak intensity satisfies the following relationship:

[0031] (I 29.6° +I 31.0° ) / (I 33.6° +I 36.1° )=0.10~0.30 (1)

[0032] In any cross section of the silicon nitride sintered body, the area ratio of the grain boundary phase per unit area of 100 μm×100 μm is 25-40%, and the workability coefficient is 0.100-0.120.

[0033] First, conditions for performing XRD analysis will be described. The measurement surface is an arbitrary surface or an arbitrary cross-section of...

no. 2 approach

[0085] A second embodiment is a sliding member using the silicon nitride sintered body of the first embodiment. Examples of the sliding member include bearing balls, rollers, check balls, wear pads, plungers, rollers, and the like. These sliding members slide with counterpart members made of metal members, ceramics, and the like. In order to improve the durability of the sliding surface, it is preferable to design a polished surface having a surface roughness (Ra) of 0.5 μm or less, further 0.1 μm or less, more preferably 0.05 μm or less. By making the sliding surface flat, the durability of the silicon nitride sintered body can be improved, and the aggressiveness to the counterpart member can be reduced. By reducing the aggressiveness to the counterpart member, since the consumption of the counterpart member can be reduced, the durability of the device incorporating the slide member can be improved.

[0086] Examples of devices incorporating sliding members include products...

Embodiment 1~13 and comparative example 1~2

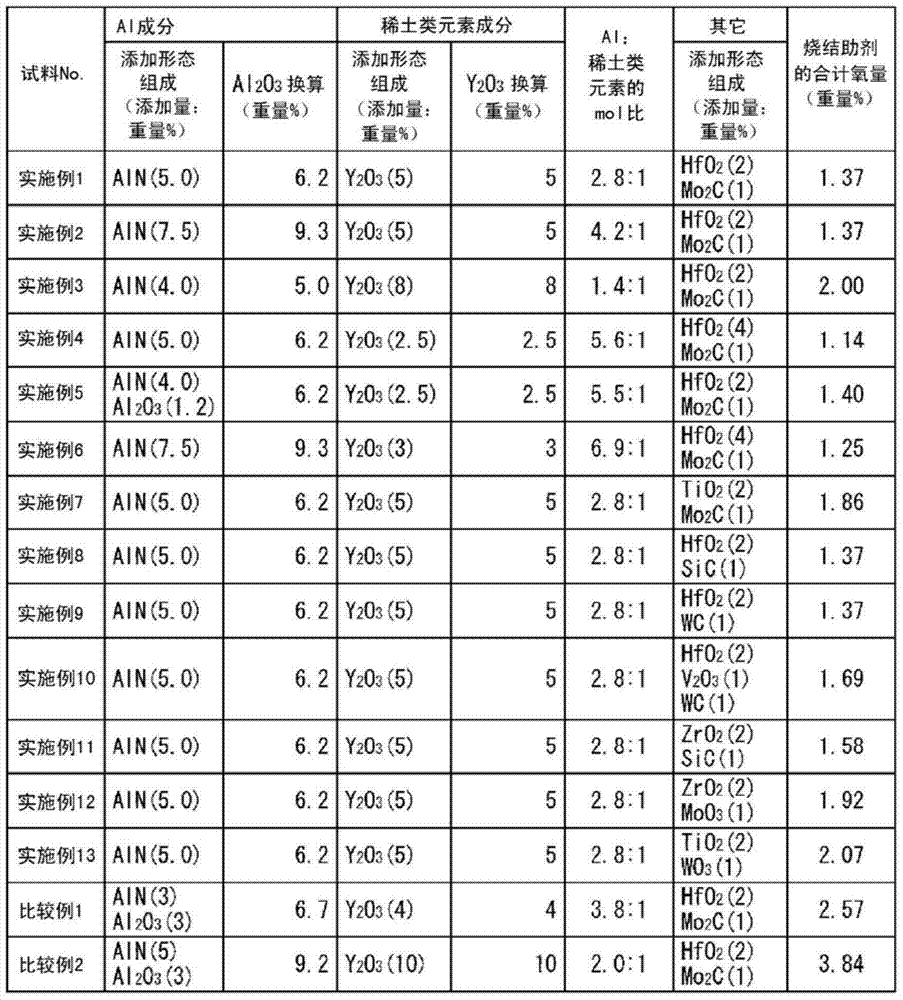

[0105]As silicon nitride powder, α-Si 3 N 4 The ratio is 99% by mass of powder. Next, sintering aids shown in Table 1 were prepared as sintering aids. In addition, as the sintering aid powder, the average particle diameter of 1.3 micrometers or less was used.

[0106] Table 1

[0107]

[0108] Next, the aforementioned silicon nitride powder and sintering aid powder were blended and wet-mixed by a ball mill for 50 hours. Mixing is performed so that the TI value at this time is 1.0 to 2.0. Next, after being taken out from the solution, dried, mixed with a binder, and subjected to a mixing process with a ball mill for 20 hours, mixed raw material powders were prepared respectively.

[0109] Next, each raw material mixture was molded by a molding machine, and then degreased at 460°C. Next, the degreased body is sintered in a nitrogen atmosphere at 1700-1800°C for 4-6 hours.

[0110] Next, HIP treatment is performed on the obtained sintered body. The HIP treatment is car...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com