Polyacrylamide-based surface paper strength agent and method for producing paper

A polyacrylamide-based, paper strength agent technology, applied in paper, papermaking, paper coating and other directions, can solve problems such as unsatisfactory, and achieve excellent paper strength enhancement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] Add 223.8 g of water to a 1L four-necked flask equipped with a stirrer, thermometer, reflux condenser, and nitrogen conduit, and also add 111.4 g of 50% acrylamide aqueous solution, 8.5 g of itaconic acid, and methacrylic acid as monomers (1). Sodium (sodiummethylylsulfonate) 1.57g, pH was confirmed to be 2.7. Next, the temperature was raised to 70°C under a nitrogen atmosphere, 0.12 g of ammonium persulfate was added as a polymerization initiator to start polymerization, and the reaction temperature was raised to 90°C. Thereafter, 97.20 g of water, 334.2 g of 50% acrylamide aqueous solution, 8.5 g of itaconic acid, and 3.39 g of sodium methacrylate sodium sulfonate (2) were added, and ammonium persulfate was also added as a polymerization initiator. 0.40 g and 163.5 g of water were added when the estimated viscosity was 4500 mPa·s at 25°C. The pH was adjusted to 6.5 with 25% sodium hydroxide to obtain a polyacrylamide-based surface paper strength agent with a solid co...

Embodiment 2~12、 comparative example 1~5

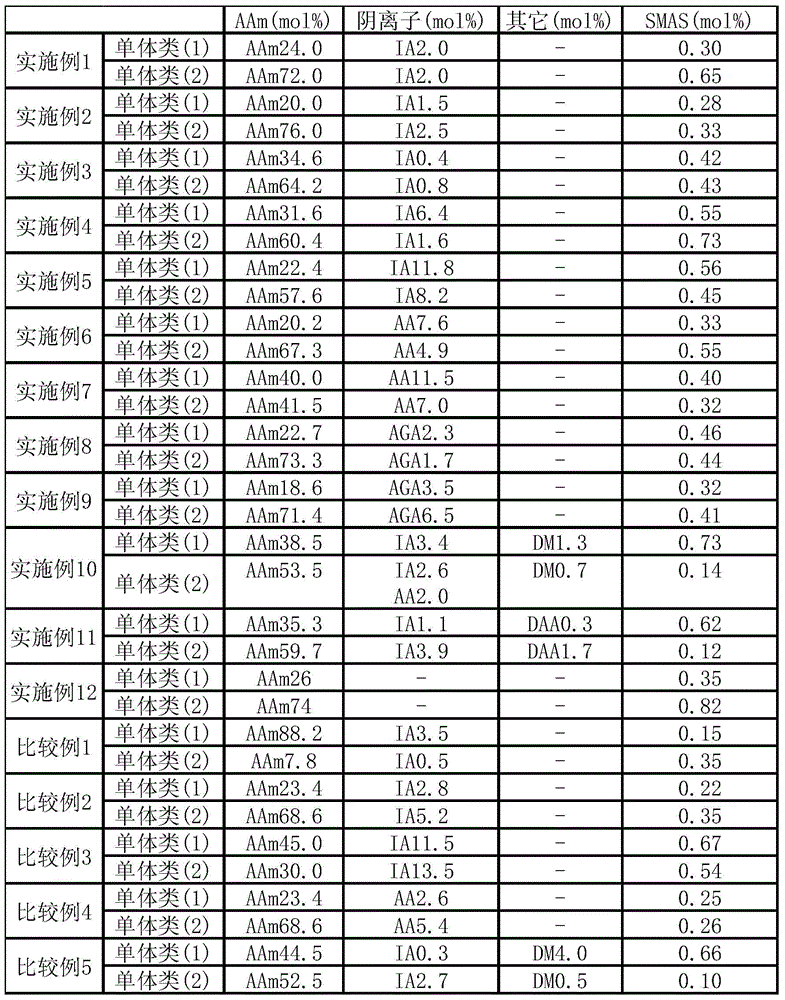

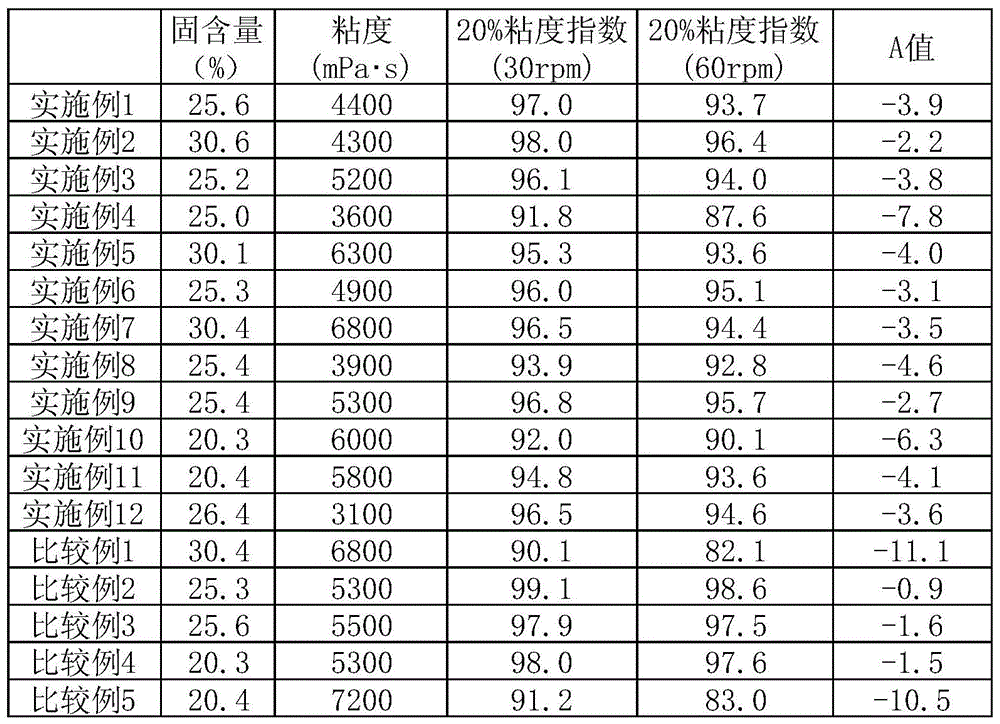

[0056] Except that the compositions of the monomers (1) and the monomers (2) were changed as shown in Table 1, a polyacrylamide-based surface paper strength agent was obtained in the same manner as in Example 1. In addition, the usage-amount of the other monomer shown in Table 1, sodium methacryl sulfonate (SMAS) is the usage-amount with respect to the total 100 mol% of acrylamide (AAm) and anionic vinyl monomer. As in Example 1, the pH of the obtained polyacrylamide-based surface paper strength agent was adjusted to 6.5, and the solid content concentration and viscosity (25° C.) were measured.

[0057] In addition, as in Example 1, these polyacrylamide-based surface paper strength agents were adjusted to a solid content concentration of 20% and a temperature of 25°C, and the A value was obtained. Table 2 shows the results.

[0058] [Table 1]

[0059]

[0060] The meanings of the symbols in Table 1 are as follows:

[0061] AAm: acrylamide

[0062] DM: Dimethylaminoethyl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com