paper strength enhancer

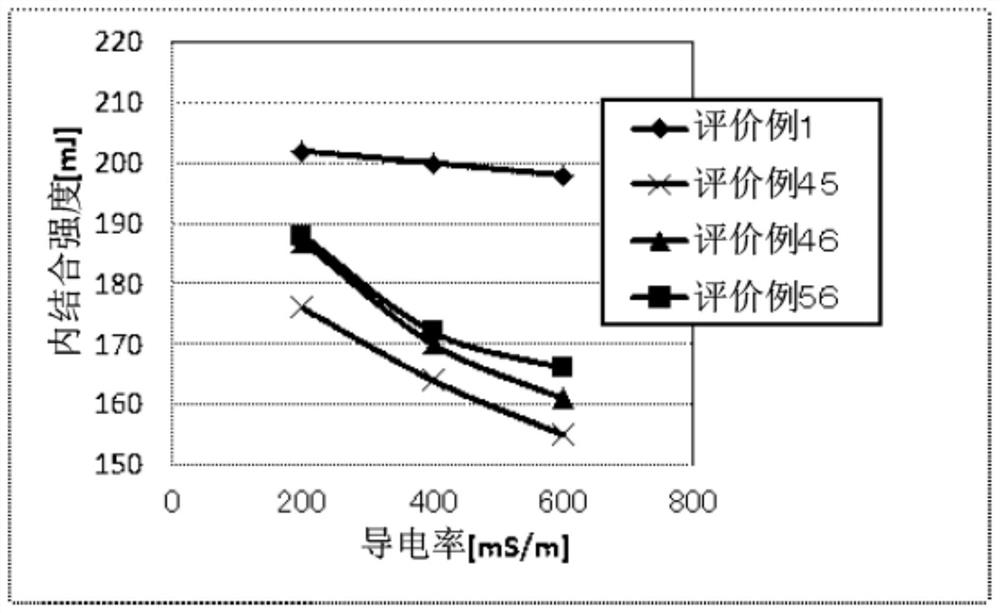

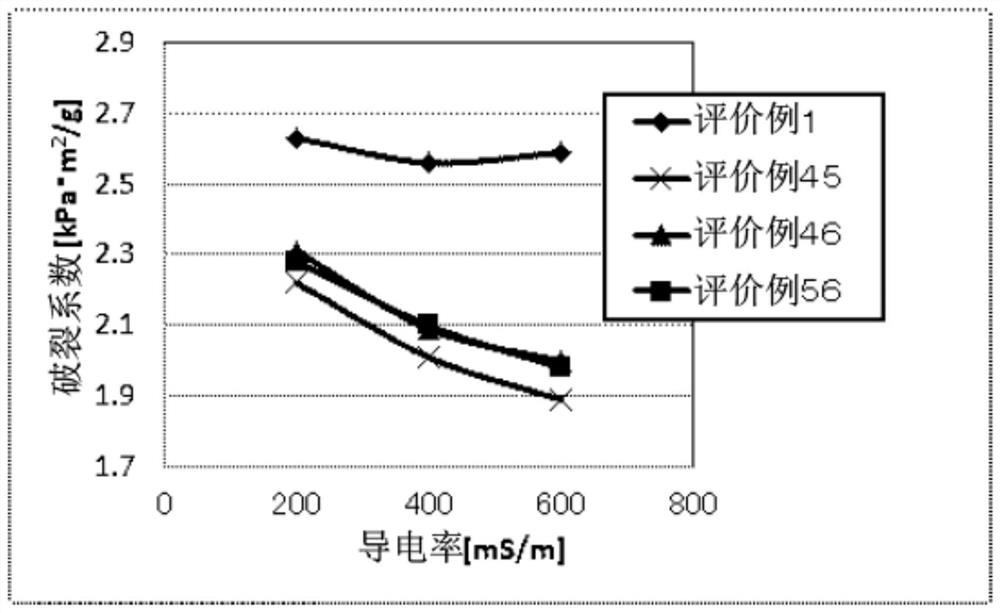

A technology of paper strength enhancer and metal ions, which is applied in the direction of enhancer addition, papermaking, paper, etc., can solve the problems of difficulty in obtaining the effect of improving paper strength, the influence of electrical conductivity changes, and difficult paper strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0064] Examples of the present invention are described below, but the present invention is not limited by these examples. It should be noted that unless otherwise stated, % is based on mass, and mol % is a ratio when the total amount of monomers is set to 100 mol %.

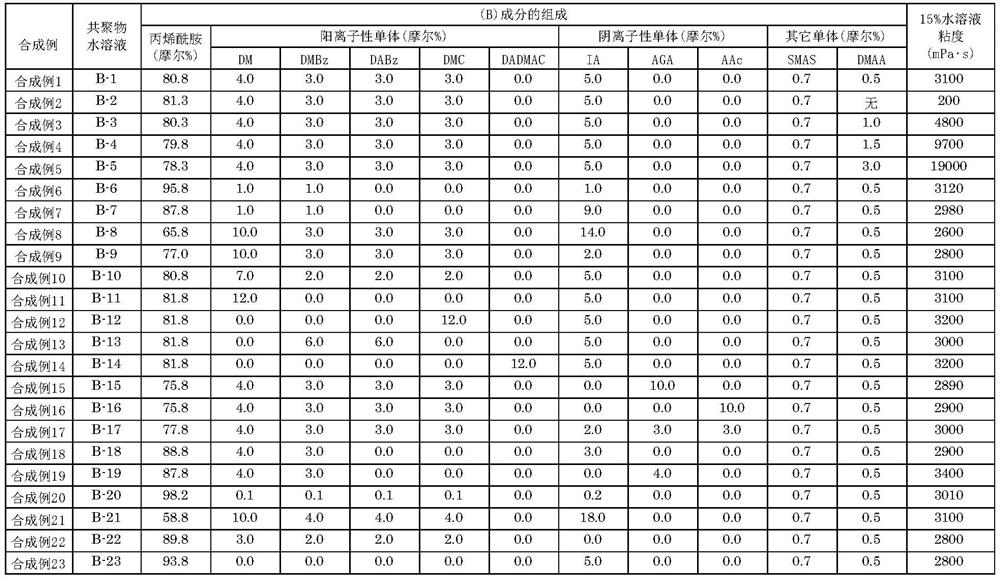

[0065] (Synthesis of component (B))

Synthetic example 1

[0067] Into a 1-liter four-necked flask equipped with a stirrer, a thermometer, a reflux condenser, and a nitrogen conduit, 280.00 g of water was put, and as monomers (1), 93.91 g (36.70 mol %) of a 50% aqueous solution of acrylamide, dimethacrylic acid 11.32 g (4.00 mol %) of dimethylaminoethyl methacrylate, 14.02 g (3.00 mol %) of 80% dimethylaminoethyl methacrylate methyl chloridequaternized aqueous solution, 76 % dimethylaminoethyl methacrylate benzyl chloride-quaternized aqueous solution 20.16g (3.00 mol%), 76% dimethylaminoethyl acrylatebenzyl chloride -quaternized) aqueous solution 19.17g (3.00mol%), sodium methallylsulfonate (sodium methallylsulfonate) 0.85g (0.30mol%), adjusted to pH3.0 with 30% sulfuric acid aqueous solution. Next, the temperature was raised to 65°C under a nitrogen atmosphere, ammonium persulfate was added as a polymerization initiator to start a polymerization reaction, and the temperature in the reaction vessel was raised to 90°C. Then, 359.00 g ...

Synthetic example 2~5

[0069]The same procedure as in Synthesis Example 1 was carried out, except that the amount of the crosslinkable monomer was changed as shown in Table 1, and the increased or decreased amount was supplemented with acrylamide to obtain aqueous copolymer solutions (B-2 to B- 5). The obtained aqueous copolymer solution was adjusted to a solid content of 15.0% and a pH of 3.0. Table 1 shows the results of the viscosity at 25°C measured with a Brookfield viscometer.

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com