Surface paper strength agent, coating liquid, and method for producing paper

A technology of paper strength strengthening agent and aqueous solution, which is applied in the direction of strengthening agent addition, papermaking, textiles and papermaking, etc. It can solve the problems of insufficient paper strength enhancement effect and achieve excellent paper strength enhancement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

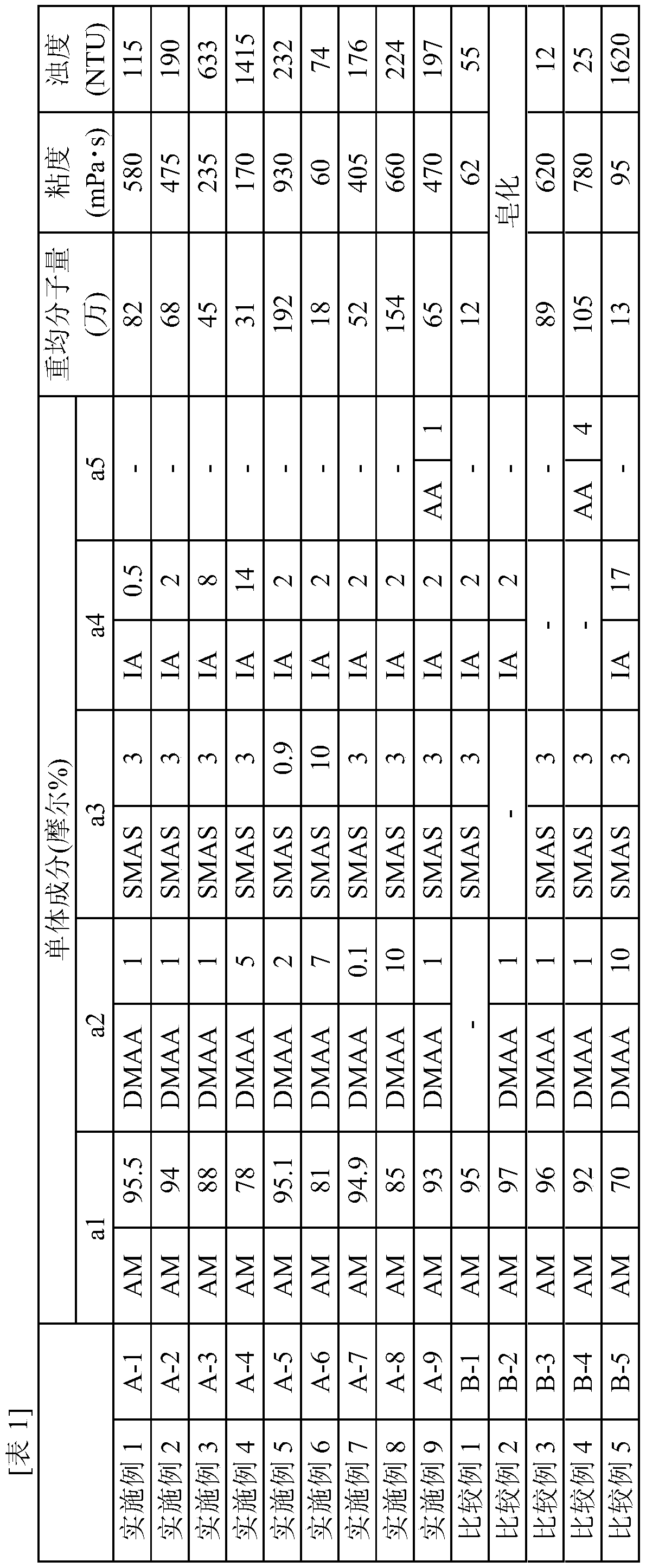

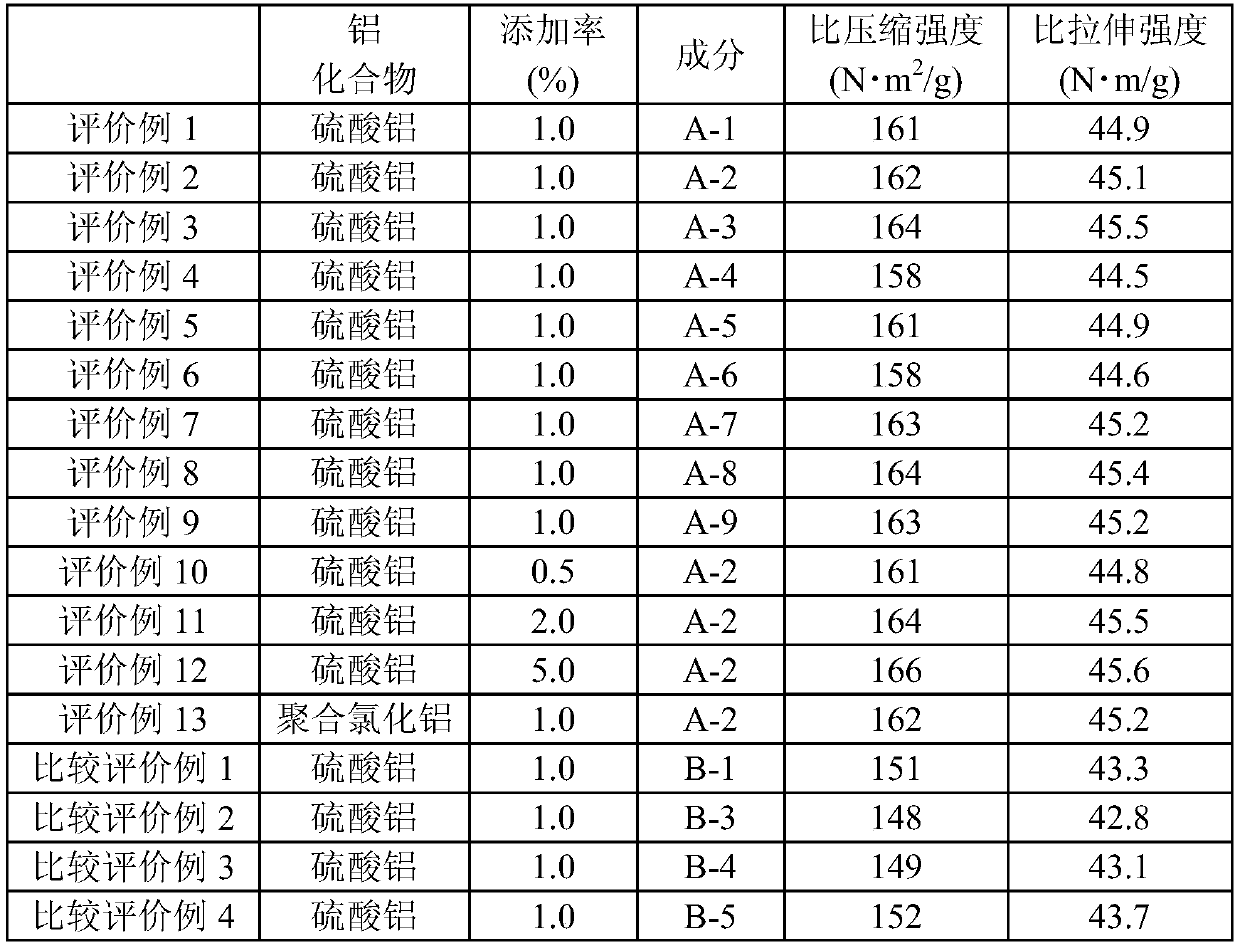

[0078] Add 522 parts of ion-exchanged water to a reaction device equipped with a stirrer, a thermometer, a reflux condenser, a nitrogen gas introduction tube, and two dropping funnels, feed nitrogen gas to remove oxygen in the reaction system, and heat to 85°C. Separately, 767.8 parts of 50% AM aqueous solution, 5.6 parts of DMAA, 26.8 parts of SMAS, 3.7 parts of IA and 305 parts of ion-exchanged water were put into the dropping funnel (1). In addition, 1.5 parts of APS and 150 parts of ion-exchanged water were charged into the dropping funnel (2). Then, it was added dropwise to the reaction device (1) from the dropping funnel (1) and the dropping funnel (2) over 3 hours. After the dropwise addition, 0.5 parts of APS and 10 parts of ion-exchanged water were added, and when the estimated viscosity measured by a B-type viscometer reached about 550 mPa·s (temperature 25° C., solid content concentration 20%), the polymerization was terminated and carried out. After cooling, polym...

Embodiment 2~9、 comparative example 1~5

[0080] Using the same method as in Example 1, it was converted into the monomer components shown in Table 1 and synthesized to obtain components (A-2) to (A-9) and (B-1) to (B-5) Ingredients. In addition, since (B-2) component gelled during manufacture, it was not used for the following evaluation.

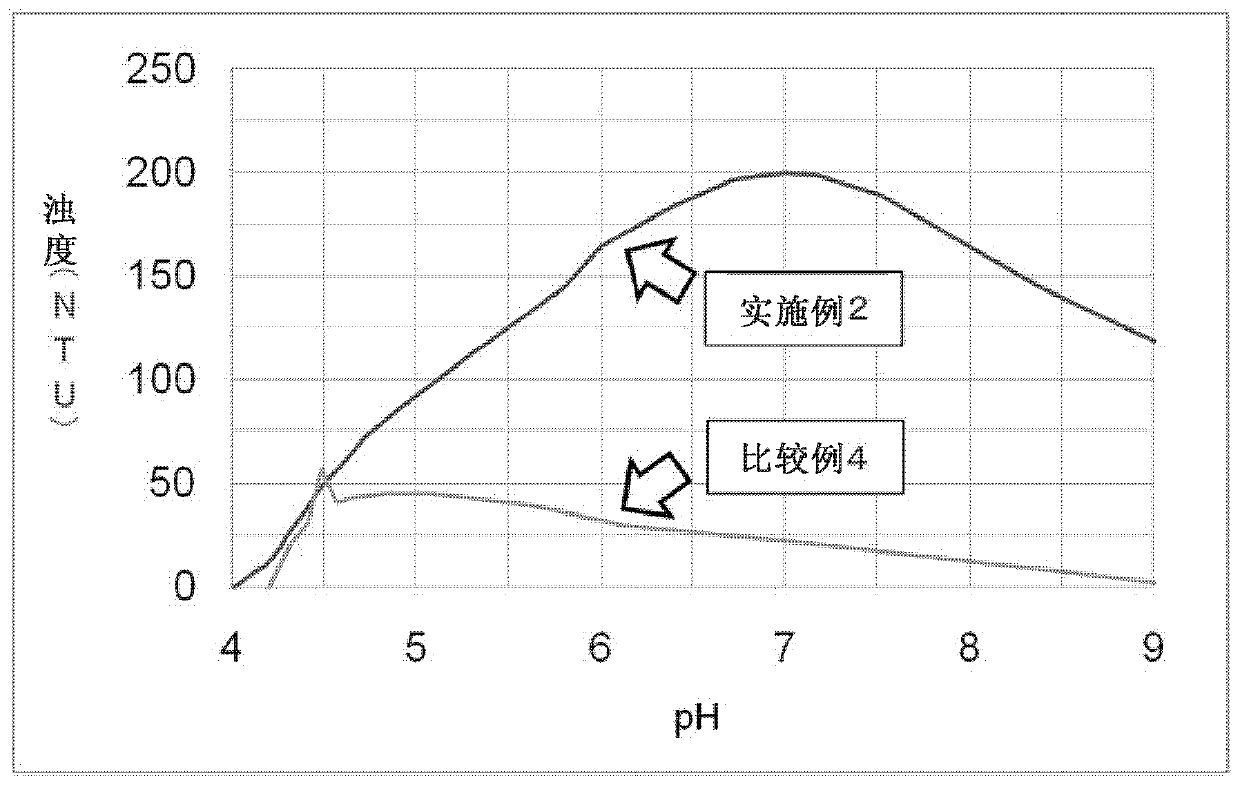

[0081] [Preparation of aqueous solution for turbidity measurement]

[0082] 10 parts of aluminum sulfate·14-18 hydrate (manufactured by Wako Pure Chemical Industries, Ltd.) and 990 parts of ion-exchanged water were mixed in advance to prepare an aqueous aluminum sulfate solution with a solid content concentration of 1%. Next, after mixing 5 parts of component (A-1) (solid content: 1 part) and 45 parts of ion-exchanged water, 50 parts of the above-mentioned aluminum sulfate aqueous solution was added to prepare an aqueous solution for turbidity measurement (solid content concentration-(A) ingredients 1%, aluminum sulfate 0.5%). Moreover, the aqueous solution was prepared similar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| Adhesion amount | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com