Paper strength enhancer for high-ash paper, method for producing high-ash paper, and high-ash paper

A paper strength enhancer and paper separation technology, which can be used in the field of paper strength enhancer for high ash paper and high ash paper, can solve problems such as unreachable, and achieve reduced paper texture disorder, excellent internal strength, and paper strength. Enhance the effect of good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

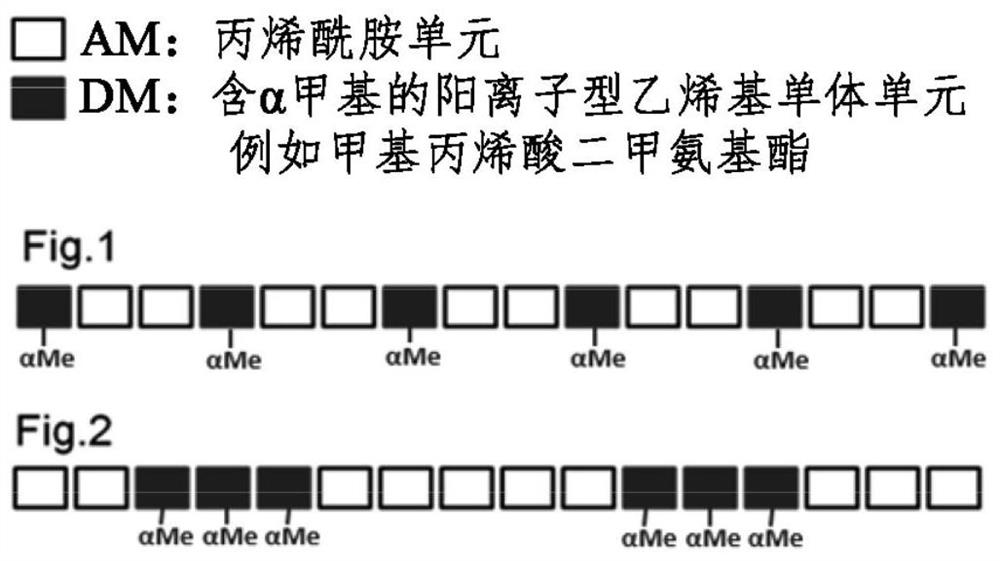

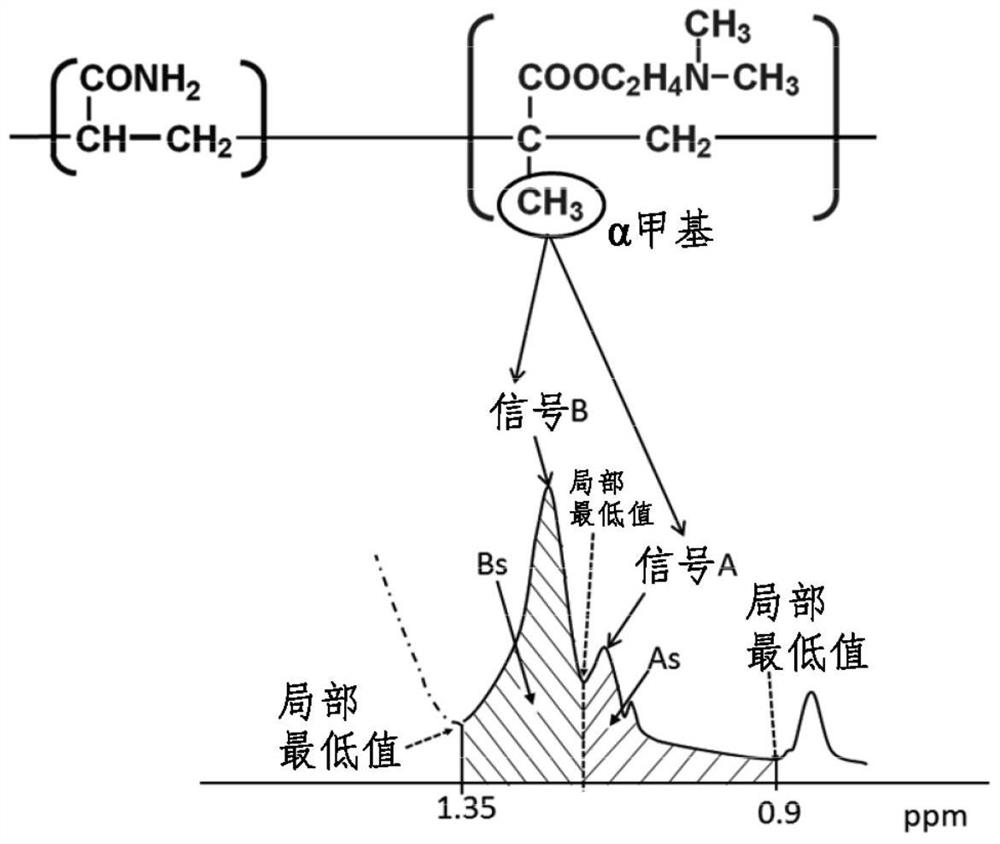

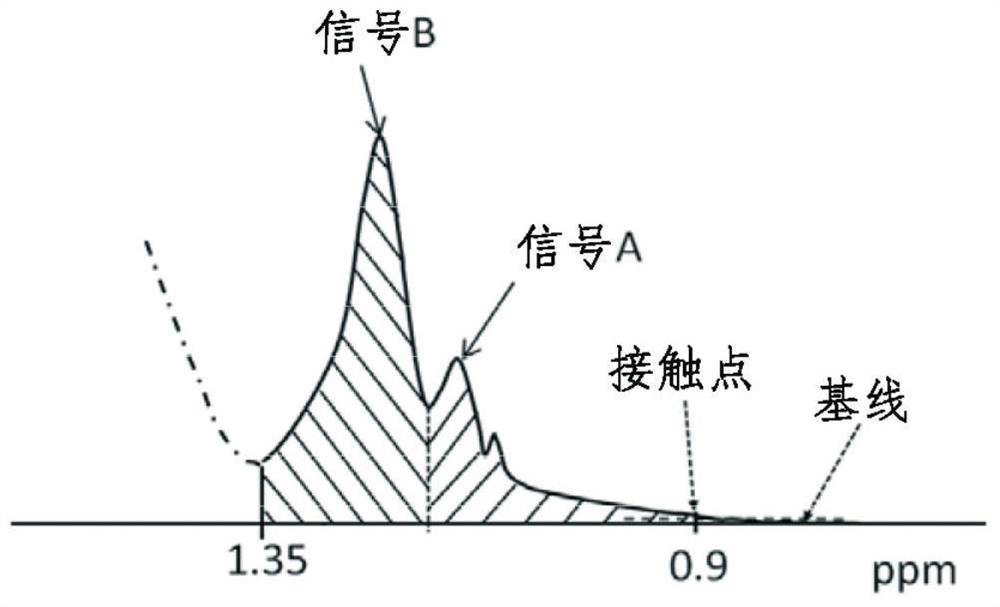

Method used

Image

Examples

Embodiment 1

[0114] Add 401.4 parts of ion-exchanged water to a reaction vessel equipped with a stirrer, a thermometer, a reflux condenser, a nitrogen conduit, and three dropping funnels (hereinafter referred to as funnel 1, funnel 2, and funnel 3 in turn), After directly blowing nitrogen gas to remove oxygen in the reaction vessel, the temperature of the ion-exchanged water was set to 90°C.

[0115] Then, in the funnel 1, as the monomer mixture (I), 79.04 parts of 50% acrylamide aqueous solution, 24.37 parts of dimethylaminoethyl methacrylate, 3.99 parts of 80% acrylic acid, N,N-dimethylacrylamide 0.18 parts, 0.292 parts of sodium methallyl sulfonate, 11.91 parts of 62.5% sulfuric acid, and 61.42 parts of ion-exchanged water were further adjusted to pH 4.5 with sulfuric acid.

[0116] Then, in the funnel 2, as the monomer mixture (II), 386.98 parts of 50% acrylamide aqueous solution, 10.44 parts of dimethylaminoethyl methacrylate, and quaternized benzyl chloride of 75% dimethylaminoethyl ...

Embodiment 2~15

[0121] Except that monomer mixture (I) and monomer mixture (II) and initiator solution are changed into the mixture of composition as shown in Table 1, other obtain amphoteric polyacrylamide (any one) with the same method as Example 1 Solid content concentration 15.0%).

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com