Polyacrylamide-based additive for papermaking, method for producing same, and method for producing paper

A polyacrylamide-based, polyacrylamide technology, used in papermaking, reinforcing agent addition, textiles and papermaking, etc., can solve the problems of paper strength enhancement effect and unsatisfactory water drainage, and achieve good water drainage and paper production. Excellent force enhancement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

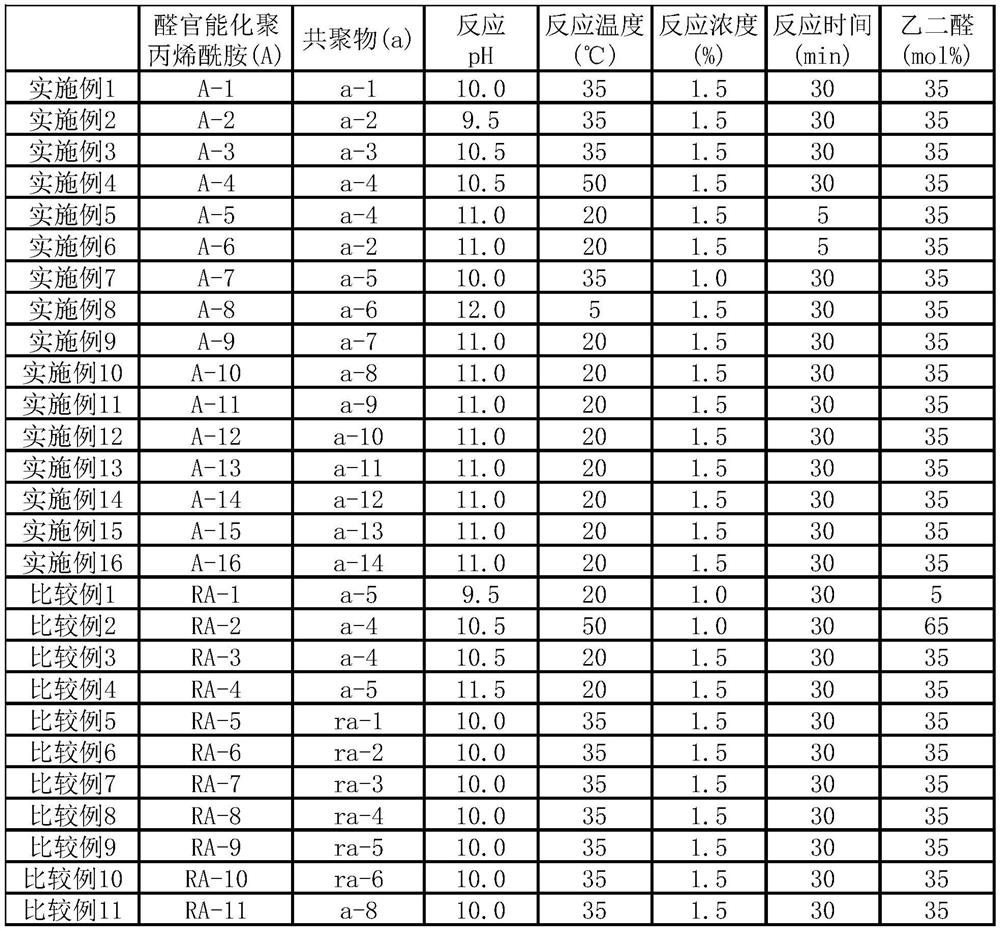

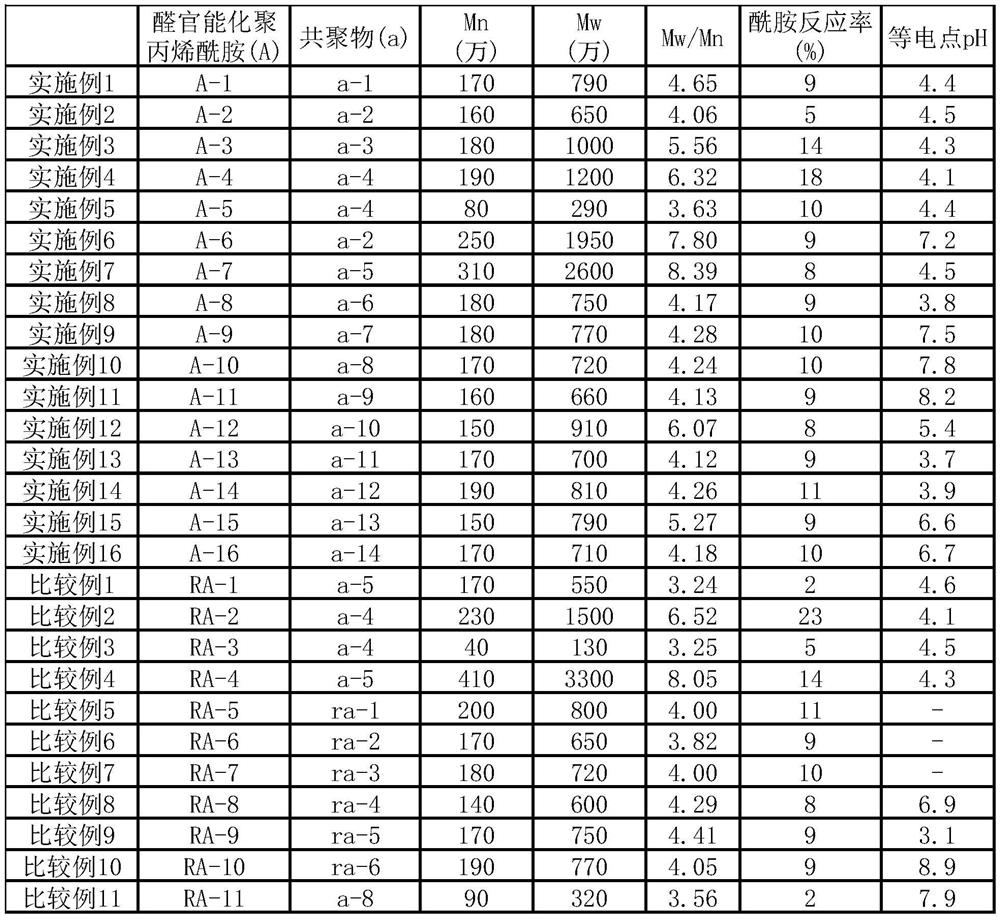

Examples

Embodiment

[0083] The following examples and comparative examples are given to further specifically describe the present invention, but the present invention is not limited by these examples. It should be pointed out that in each example, unless otherwise stated, parts and % are based on mass. The physical property value of each example is the value measured by the following method.

[0084] The number average molecular weight, weight average molecular weight, and molecular weight distribution were obtained by the GPC-MALS method in which a multi-angle light scattering detector was connected to the GPC under the following measurement conditions.

[0085] HPLC: Agilent1100 series

[0086] Column: Showa Denko Co., Ltd. SHODEX SB806MHQ

[0087] Eluent: Phosphate buffer containing sodium nitrate (pH3)

[0088] Flow rate: 1.0ml / min

[0089] Detector 1: Multi-angle Light Scattering Detector DAWN manufactured by Wyatt Technologies, USA

[0090] Detector 2: Differential Refractive Index Det...

manufacture example 1

[0093] Put water 260.00g, 50% acrylamide aqueous solution 126.81g, dimethylacrylamide 0.10g, 30 15.60 g of aqueous sulfuric acid solution, 15.72 g of dimethylaminoethyl methacrylate, and 1.27 g of sodium methacrylate. Next, the temperature was raised to 60° C. under a nitrogen atmosphere, 0.24 g of ammonium persulfate was added as a polymerization initiator to start polymerization, and the reaction temperature was raised to 90° C. Thereafter, 180.00 g of water, 132.49 g of a 50% aqueous solution of acrylamide as monomers (2), 0.10 g of dimethylacrylamide, 5.40 g of acrylic acid, and 1.27 g of sodium methacrylsulfonate were added, and ammonium persulfate was further added. 0.48 g, when the estimated viscosity at 25° C. reached 3000 mPa·s, 290.0 g of water was immediately added to obtain an amphoteric polyacrylamide copolymer (a-1) with a solid content of 15.0%. Table 1 shows the measurement results of the proportion (mol %), number average molecular weight, weight average mole...

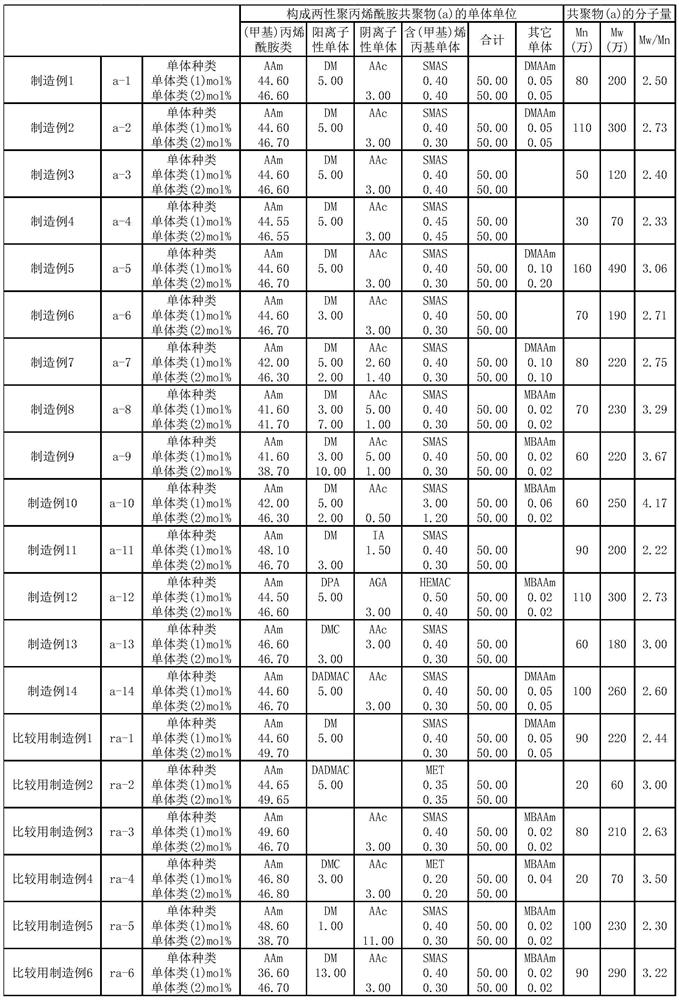

manufacture example 2~14、 comparative manufacture example 1~6

[0095] Except that the composition of monomers (1) and monomers (2) has been changed as shown in Table 1, it is all carried out the same as Manufacturing Example 1, and an amphoteric polyacrylamide copolymer ( a-2)~(a-14), (ra-1)~(ra-6). Ratio (mol%), number average molecular weight, weight average molecular weight, molecular weight The measurement results of the distribution are given in Table 1.

[0096] [Table 1]

[0097]

[0098] The meanings of the abbreviations in Table 1 are as follows:

[0099] AAm: acrylamide

[0100] DM: Dimethylaminoethyl methacrylate

[0101] DMC: 2-(methacryloyloxy)-N,N,N-trimethylethylammonium chloride

[0102] (2-(methacryloyloxy)-N,N,N-trimethylethanammonium chloride)

[0103] DPA: N-(2-dimethylaminoethyl)acrylamide (N-[2-(dimethylamino)ethyl]acrylamide)

[0104] DADMAC: Diallyl Dimethyl Ammonium Chloride

[0105] IA: itaconic acid

[0106] AGA: 2‐Acrylamide-N-glycolic acid

[0107] AAc: acrylic acid

[0108] SMAS: Sodium Methacry...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com