Papermaking additive, paper, and paper manufacturing method

A manufacturing method and additive technology, which is applied in the direction of adding paper forming aids, papermaking, and reinforcing agents, which can solve the problems of paper quality reduction and inability to obtain paper strength enhancement effects, and achieve excellent paper strength effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0111] 323.60 g of water, 136.13 g of a 50% acrylamide aqueous solution as monomers (1), and 80% dimethyl methacrylate were charged into a 1-liter four-neck flask including a stirrer, a thermometer, a reflux cooling tube, and a nitrogen gas introduction tube. Aminoethyl ester methyl chloride quaternary salt 36.35g, sodium methallylsulfonate (methallylsulfonate) 3.06g, N,N-dimethylacrylamide 0.28g, 1%N,N'-methylene bisacrylamide 4.32 g, adjusted to pH 3.0 with 30% sulfuric acid aqueous solution. Next, under a nitrogen atmosphere, the temperature was raised to 65°C, and ammonium persulfate was added as a polymerization initiator to start polymerization, and the reaction temperature was raised to 90°C. Then, ammonium persulfate was added, and when the polymerization rate reached 95%, 274.0 g of water, 229.48 g of 50% acrylamide aqueous solution, 7.29 g of itaconic acid, and 1.11 g of sodium methallylsulfonate were added, N,N -Monomers (2) of 0.28 g of dimethylacrylamide and 4.32...

Embodiment 2~4

[0112] Embodiment 2~4, embodiment 6~16,18,21 comparative example 1~4,6,7,9,10

[0113] Except changing the composition of monomers as shown in Table 4 and Table 5, and changing the viscosity of the additive for papermaking as shown in Table 6, it carried out similarly to Example 1, and obtained the additive for papermaking of a polyacrylamide type.

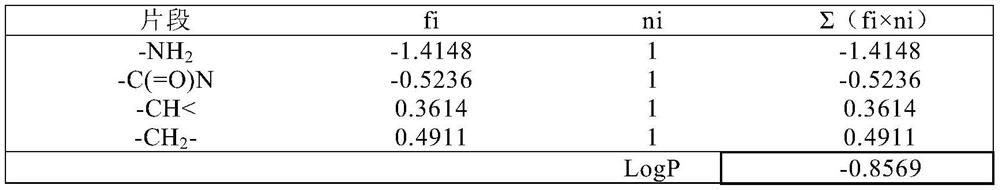

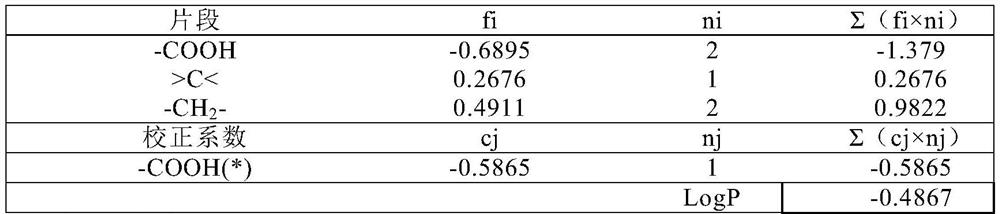

[0114] The obtained additive for papermaking was adjusted to a solid content of 20.0% and a pH of 3.0 in the same manner as in Example 1, and the results obtained by measuring viscosity, peak molecular weight, molecular weight distribution, and surface tension, and the peak molecular weight calculated from the measurement results Table 6 shows the ratio to the viscosity, the ratio of the anion equivalent to the cation equivalent calculated from the monomer composition, and the octanol / water partition coefficient.

Embodiment 5

[0116] 753.0 g of water, 329.07 g of 50% acrylamide aqueous solution, 32.45 g of 80% dimethylaminoethyl methacrylate methyl chloride quaternary salt are charged into a 1 liter four-necked flask comprising a stirrer, a thermometer, a reflux cooling pipe and a nitrogen inlet pipe. g, 6.51 g of itaconic acid, 1.38 g of sodium methallyl sulfonate, 23.13 g of 1% N,N'-methylenebisacrylamide, and then adjusted to pH 3.0 with 30% sulfuric acid aqueous solution. Under a nitrogen atmosphere, the temperature was raised to 60° C., ammonium persulfate was added as a polymerization initiator, and under a nitrogen atmosphere, the temperature was raised to 85° C. and kept warm. Ammonium persulfate was additionally added 1 hour after the start of the polymerization, and the polymerization was stopped 2 hours after the start of the reaction. After cooling, an additive for papermaking with a solid content of 20.1% was obtained. The obtained additive for papermaking was adjusted to a solid conte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface tension | aaaaa | aaaaa |

| surface tension | aaaaa | aaaaa |

| surface tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com