Method for producing a one-piece lock striker

A one-piece, locking technology, applied in the direction of manufacturing tools, applications, building locks, etc., can solve the problems of high mold load, high forming force, etc., and achieve the effect of improving bearing capacity, improving surface characteristics, and good absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

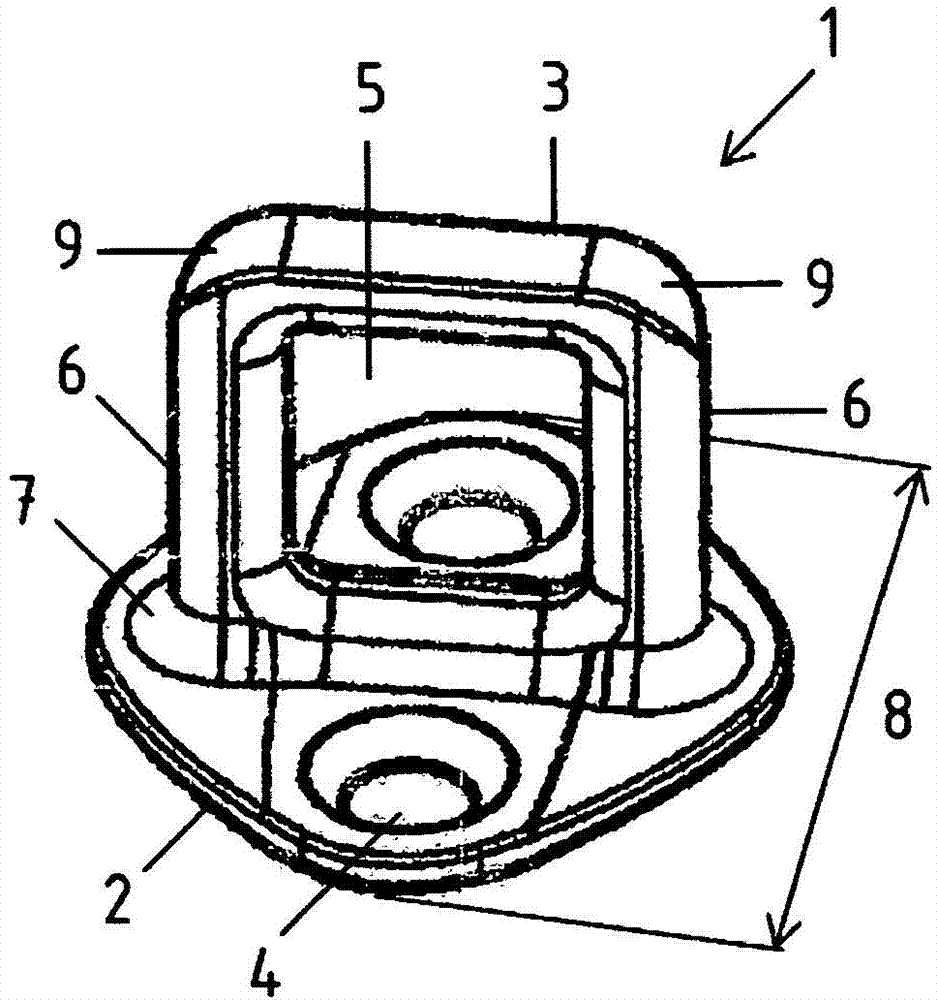

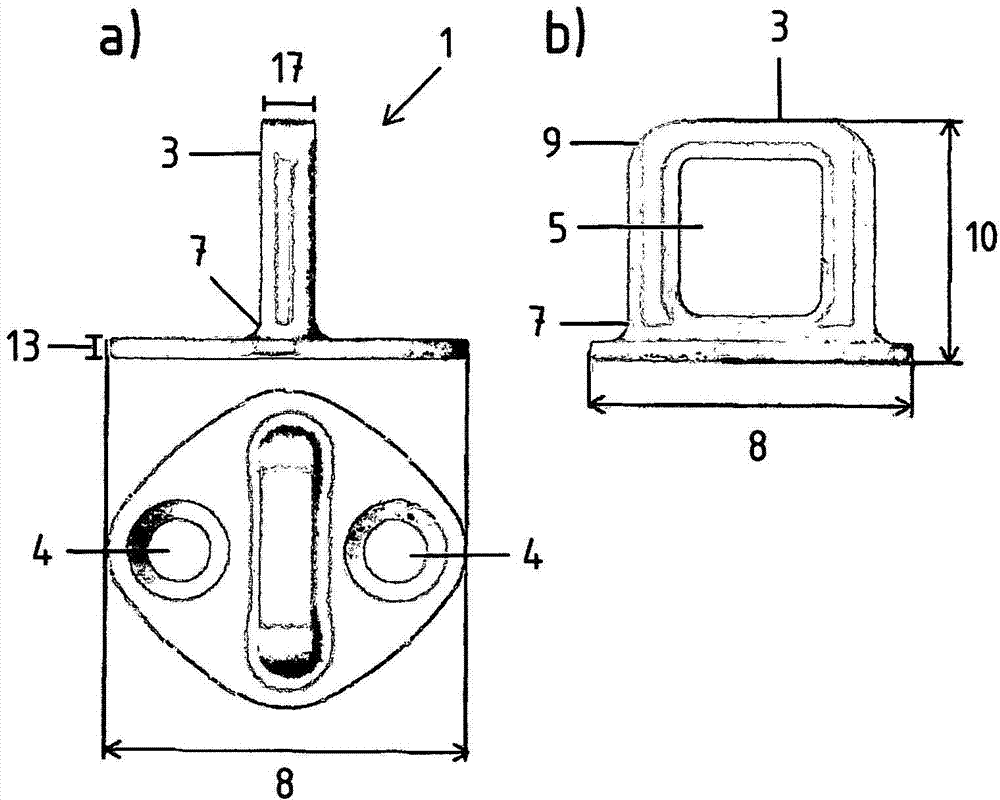

[0037] exist Figure 1 to Figure 2 The buckle 1 shown in is a typical application of the proposed solution. The proposed solution is explained below on the basis of a strike for a motor vehicle lock. However, this should not be construed as limiting the invention thereto.

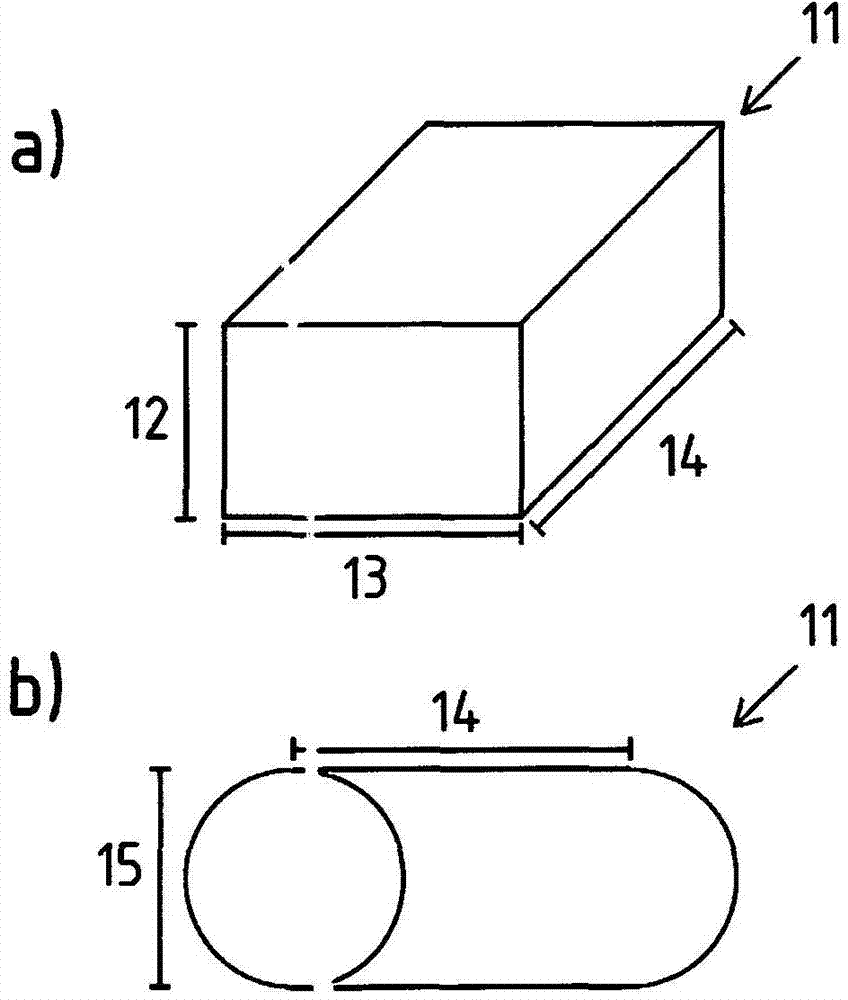

[0038] exist figure 1 The catch shown in has a base plate 2 and a bow 3 . The locking bow 3 has a recess 5 in the center in order to be able to engage with a rotary fork of the lock in the mounted state. The recess 5 can already be formed by a corresponding tool during the shaping of the original blank 11 or can be formed in a subsequent processing step, for example by stamping or cutting. Arranged on both sides of the recess 5 on the locking bow 3 are two legs 6 which are connected to the base plate 2 . The base plate 2 has in this case two openings 4 in the form of holes, which are conically designed and can be fastened, for example, to the body of a vehicle. The region between the base plate 2 and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com