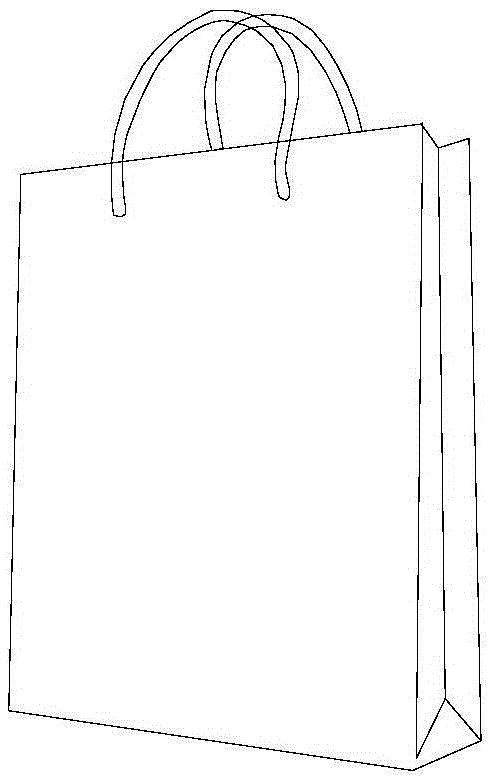

A kind of automatic production equipment and method of handbag sheet and handbag semi-finished products

A handbag sheet material and production equipment technology, which is applied in the direction of handbags, travel goods, transportation and packaging, etc., can solve the problems of unstable quality of handbags, low processing efficiency, and many forming steps, so as to improve production efficiency and speed up production. Adhesive speed, ease of penetration and volatilization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

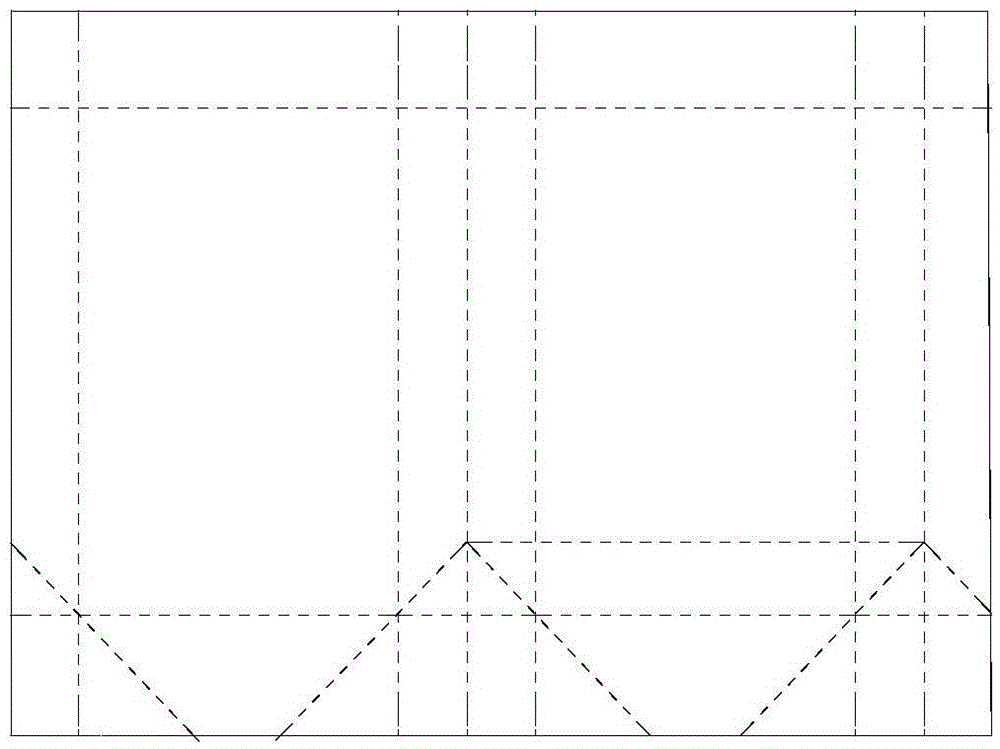

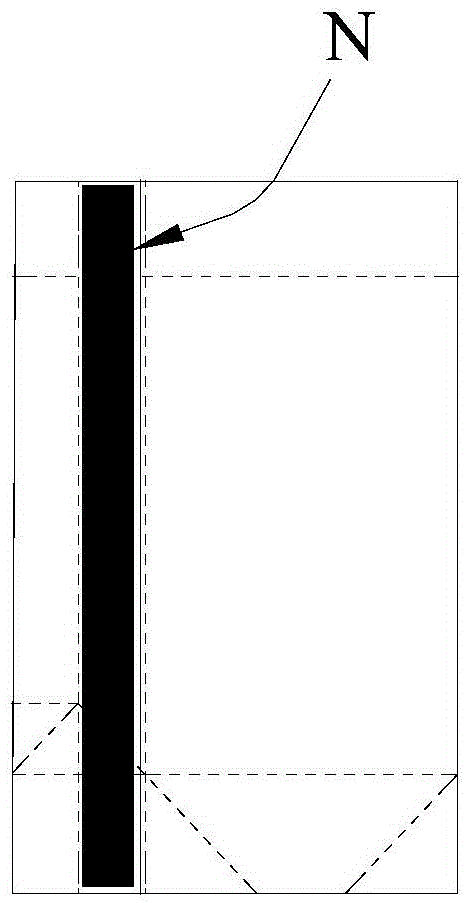

[0054] Such as image 3 As shown, the handbag sheet of the present invention includes a rectangular sheet body, and the rectangular sheet body is provided with first to third transverse indentation lines x2 to x4 from top to bottom, and the first to third horizontal indentation lines from right to left. The first to sixth longitudinal indentation lines y2 to y7, and the first to fifth oblique indentation lines k1 to k5 are arranged in sequence from right to left, and the first to third transverse indentation lines x2 to x4 are all parallel to the rectangular sheet The upper transverse side x1 and the lower transverse side x5 of the sheet body, the first to sixth longitudinal indentation lines y2~y7 are all parallel to the right longitudinal side y1 and left longitudinal side y8 of the rectangular sheet body, the first and third transverse indentations Both the crease lines x2 and x4 run through the rectangular sheet body, the second transverse crease line x3 is located between...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com