A self-contained heated shoe formwork unit for circular conveyor lines

A transport line, heating technology, applied in the field of independent heating shoe mold base units, can solve the problems of prolonging the time of polyurethane foaming and curing, adverse effects of foaming and curing effect, low utilization rate of heat energy, etc., and achieves high heating efficiency, The effect of ideal effect and high utilization rate of heat energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

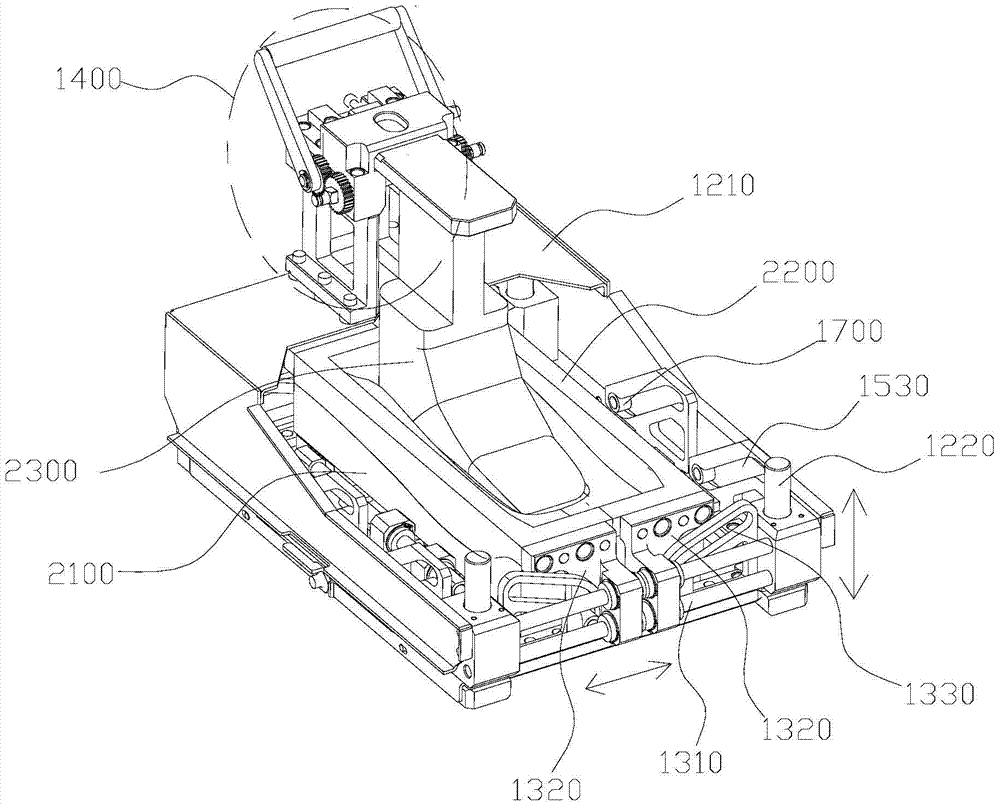

[0027] In order to make the object, technical solution and advantages of the present invention more clear and definite, the present invention will be further described in detail below with reference to the accompanying drawings and examples.

[0028] The invention discloses an independently heated shoe mold frame unit used in a circular transportation line, which includes a shoe mold frame body and a shoe mold installed in the shoe mold frame body, and also includes an independent heating mechanism. The main body of the frame is equipped with an independent heating mechanism to complete the controllable heating of the main body of each shoe mold frame, so that the heating accuracy is higher and the utilization rate of heat energy is higher.

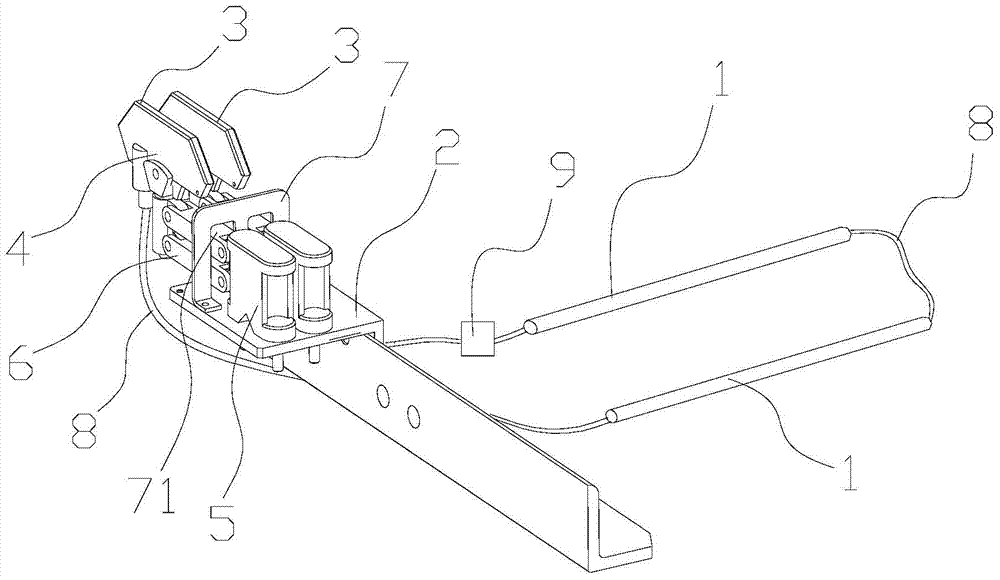

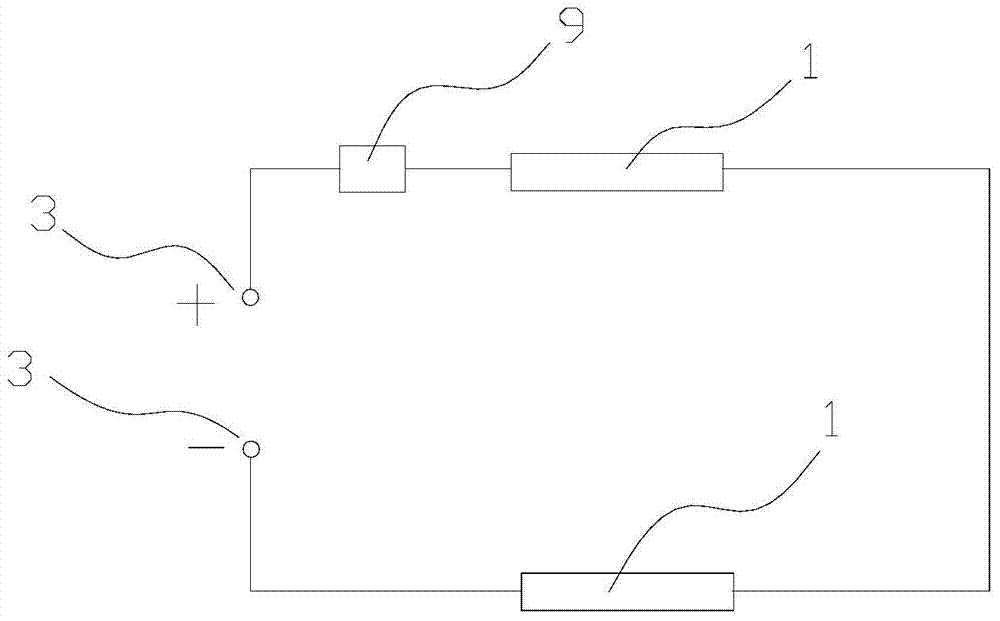

[0029] Such as figure 1 As shown, the independent heating mechanism includes at least one electric heater 1 fixedly embedded in the bottom of the shoe mold (the main body of the shoe mold frame and the shoe mold are not shown in the figur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com