A large roll material automatic edge banding tape system

A roll material and adhesive tape technology, applied in the field of automatic edge banding tape equipment, can solve the problems of high production cost, poor edge banding quality, high labor intensity, etc., achieve the effect of improving packaging quality, realizing automatic production, and avoiding unraveling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Below in conjunction with embodiment and accompanying drawing, describe the present invention in detail. The specific embodiments are only further illustrations of the invention.

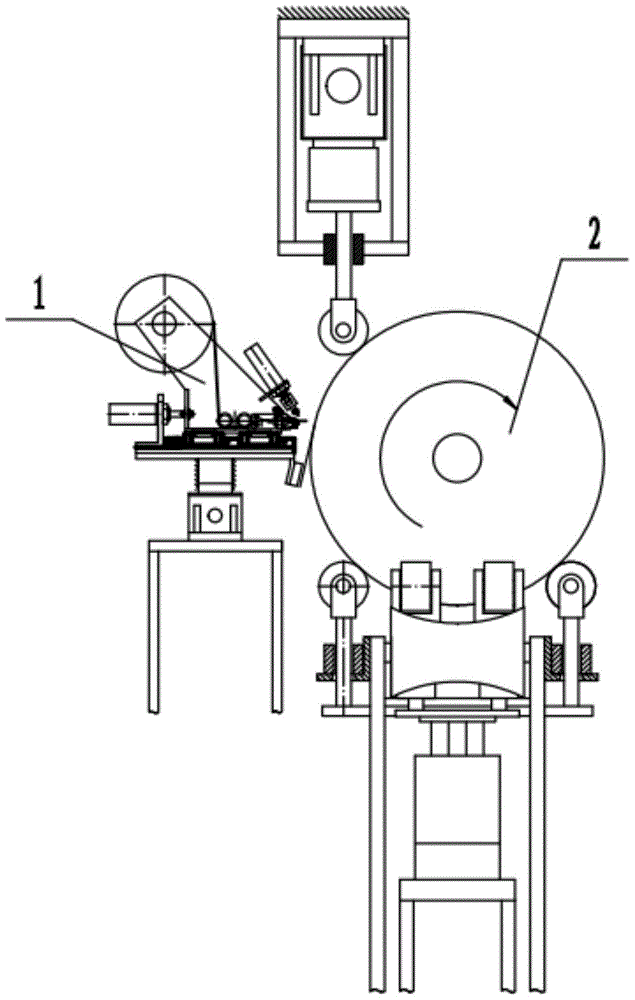

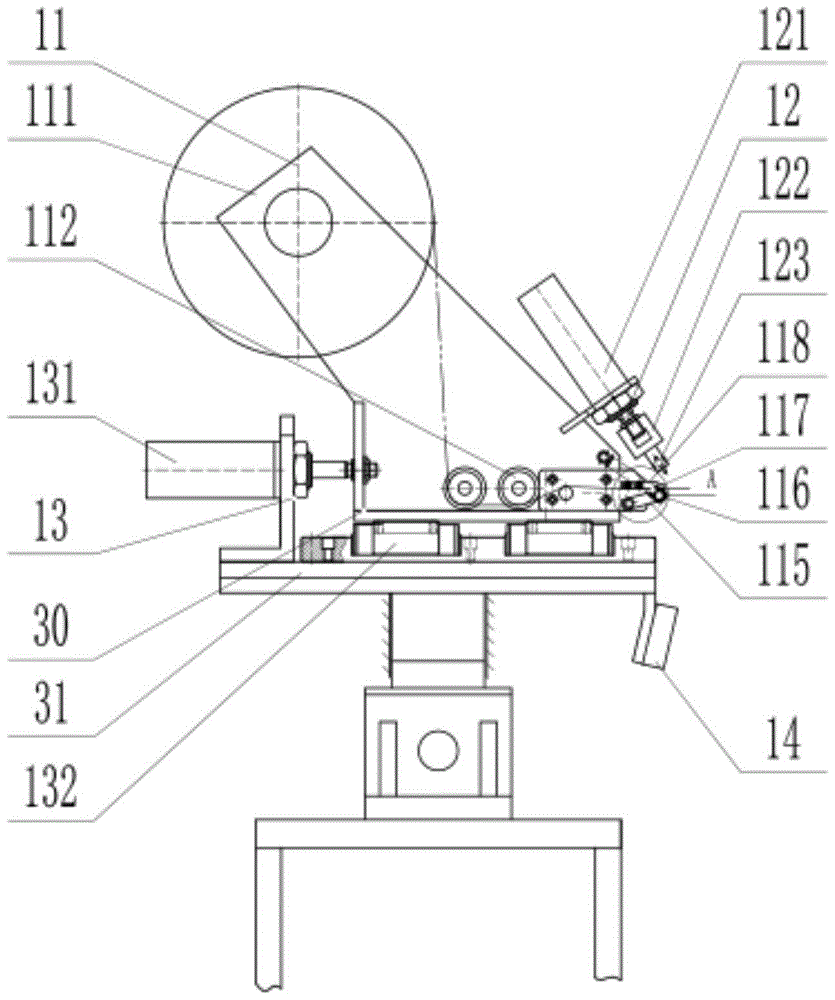

[0037] Large-scale roll material of the present invention sticks edge sealing adhesive tape system automatically (referring to Figure 1-5 ) includes an automatic roll material gluer 1 and an automatic roll material lifting and rotating device 2 .

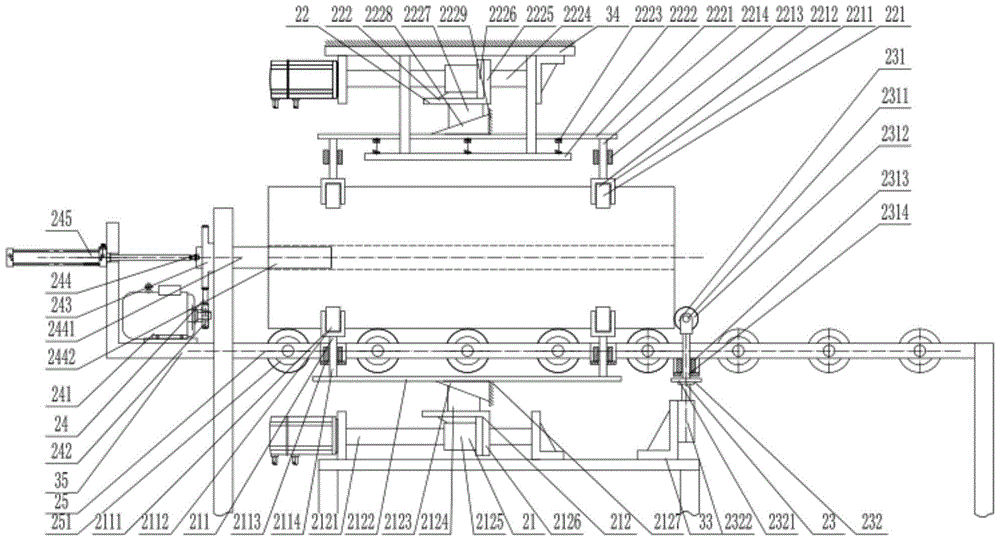

[0038] The coil material holds up the rotating device 2 (referring to figure 2 ) includes a coil material holding module 21, a coil material pressing module 22, a lateral roll blocking module 23, a power rotation module 24 and a coil material conveyor 25, and each module of the coil material supporting rotating device is installed on the coil material conveyor on the conveyor rack.

[0039] The width of the coil conveyor can accommodate the longitudinal passage of the coil, including the conveyor frame 36, the roller 251, the roller stepper mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com